Chapter 5 Adjustment Procedures

5-10 750-177

Final adjustment to fuel input must be made to produce a

minimum of smoke. A maximum smoke spot density of a No.

2 for light oil, as measured in conformance to ASTMD 2156-

63T.

Through the use of the manual flame control, slowly bring the

unit to high fire by stages while monitoring combustion for

overly rich or lean conditions. At the high fire position, the air

damper should be fully opened and the air and oil pressure

readings should be on the order of the readings given in

Chapter 5.

U. LOW OIL PRESSURE SWITCH

The L.O.P.S. prevents burner ignition, or stops its operation,

when the oil pressure is below the setpoint. Adjust the control

by turning the screw on top of control case to an indicated

pressure 10 psi below the established primary oil pressure

setting indicated on the oil supply pressure gauge. The switch

will remain in a closed position as long as the oil pressure

exceeds this setting. The control normally used automatically

resets when pressure is restored after a drop.

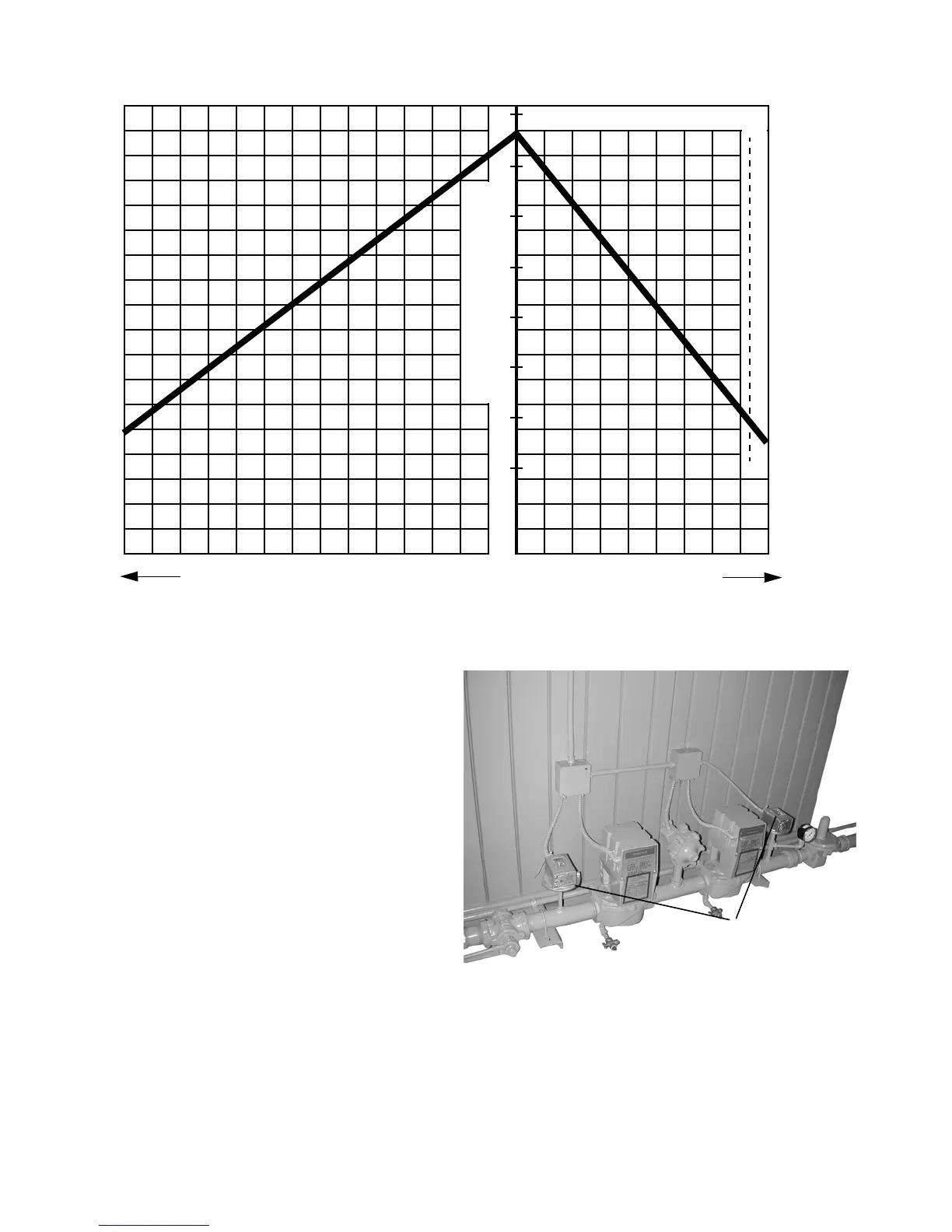

PER CENT O

2

IN FLUE GAS PER CENT CO

PER CENT EXCESS AIR

1020

3040

5060

5

6

7

8

9

10

11

12

1122334455 6

67

890

PER CENT CO

2

IN FLUE GAS

Figure 5-5: Flue Gas Analysis Chart for Natural Gas

FIRST VISIBLE TRACE OF STACK HAZE

1/10 of 1% CO = 1,000 PPM

15

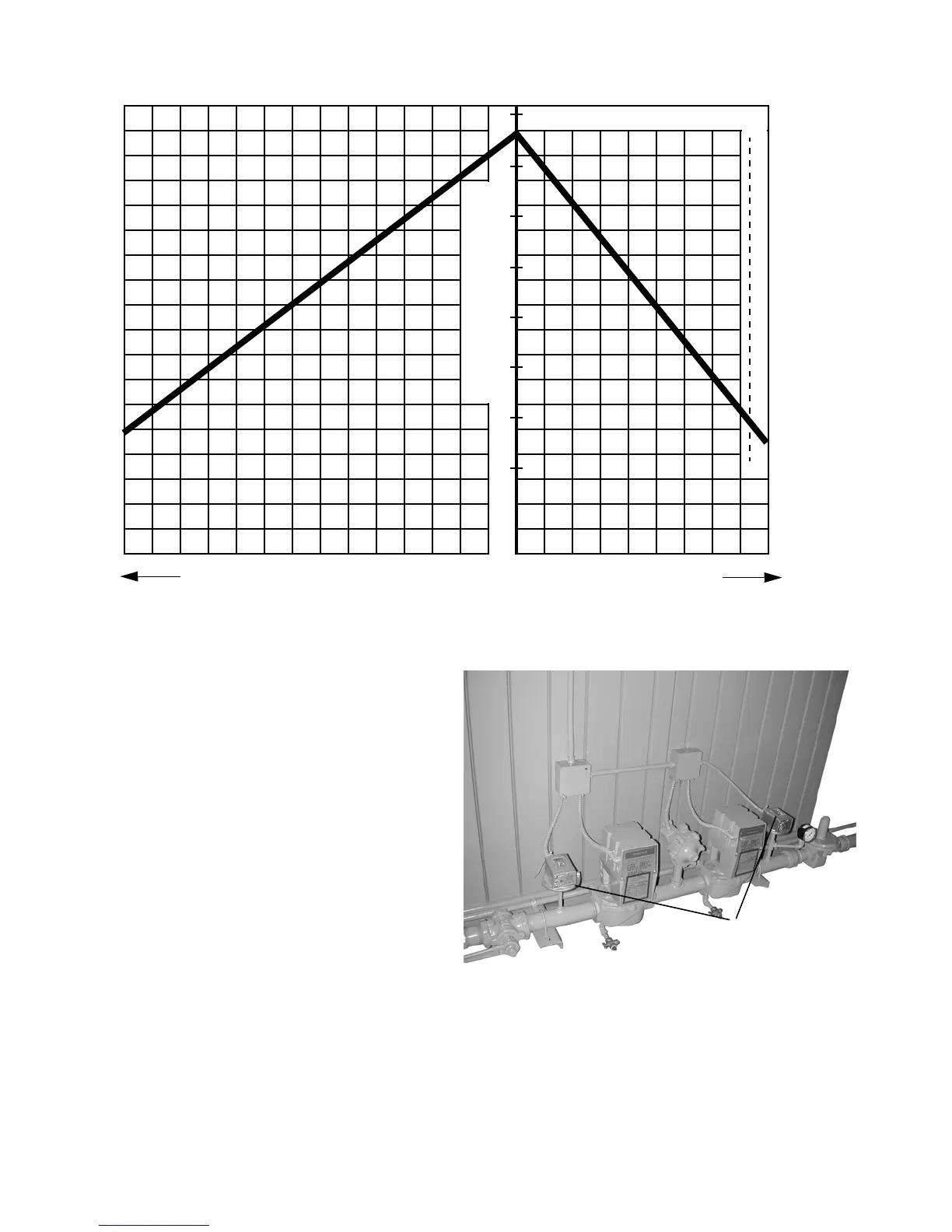

Figure 5-6: Gas Train With High and Low Pressure

Switches

Pressure Switches

Loading...

Loading...