Adjustment Procedures Chapter 5

750-177 5-9

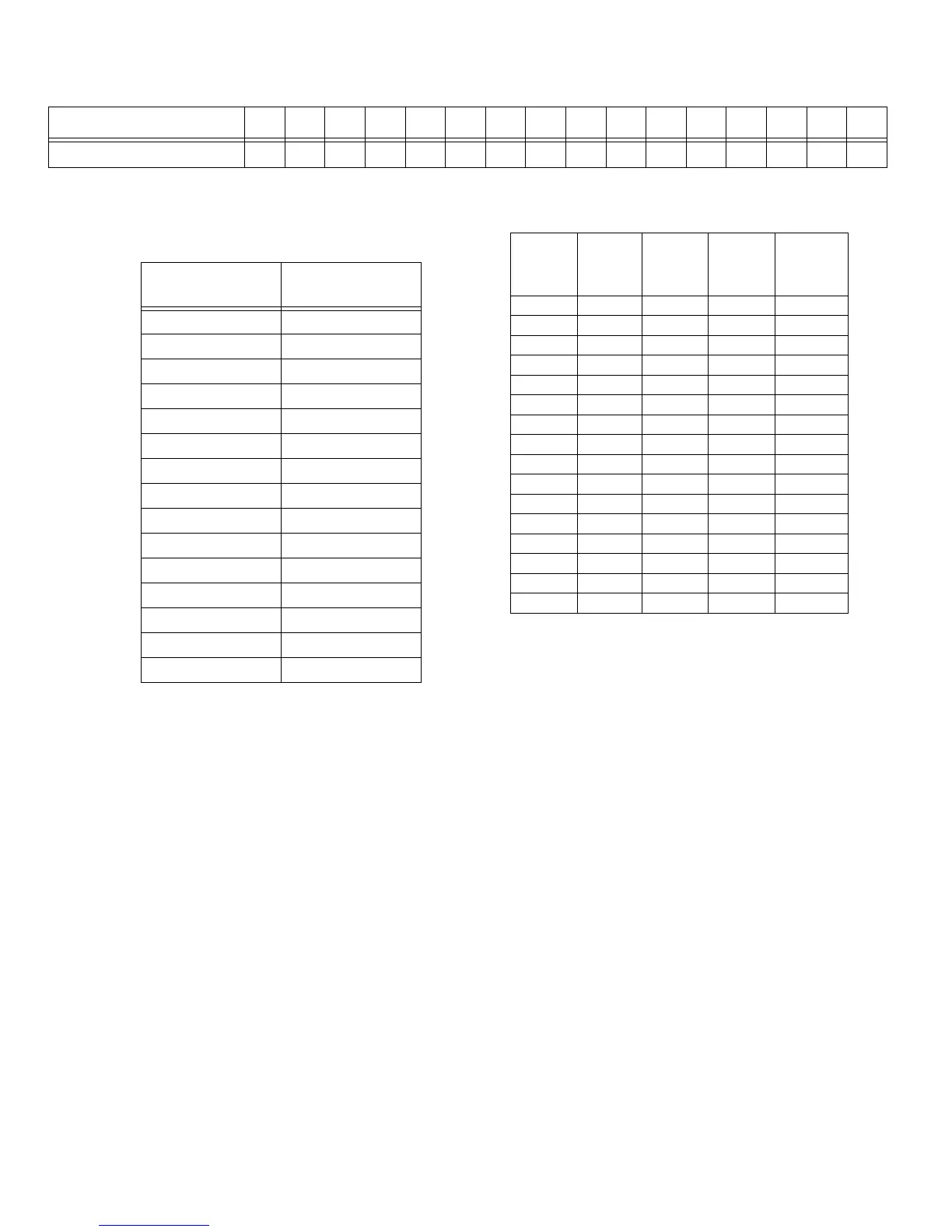

MODEL NO.

STD GAS

TRAIN SIZE

(IN.) Note 3

MIN. GAS

PRESSURE

(IN.W.C.)

Note 4

MIN. GAS

PRESSURE

(IN.W.C.)

Note 5

BURNER

MODEL

FLX-150 1 11.2 12.5 PFVG-15

FLX-200 1 19.4 21.7 PFVG-20

FLX-250 1.5 12.4 15.7 PFVG-25

FLX-300 1.5 15.9 20.7 PFVG-30

FLX-350 1.5 15.5 22.0 PFVG-35

FLX-400 1.5 18.7 27.2 PFVG-40

FLX-450 2 16.0 26.7 PFVG-45

FLX-500 2 17.6 21.0 PFVG-50

FLX-550 2 22.9 27.1 PFVG-55

FLX-600 2 20.0 24.9 PFVG-60

FLX-700 2 25.2 31.9 PFVG-70

FLX-800 2.5 19.9 22.2 PFVG-80

FLX-900 2.5 24.7 27.7 PFVG-90

FLX-1000 2.5 31.6 31.6 PFVG-100

FLX-1100 2.5 37.3 37.3 PFVG-110

FLX-1200 2.5 38.2 38.2 PFVG-120

Notes:

1. Table is based on 1,000 Btu/cu.ft natural gas and elevation to 1000

feet.

2. Minimum gas pressure also applies to 200 fuel series.

3. As an option, the standard gas train can be replaced with an

oversized design to reduce inlet gas pressure requirements.

4. Use this column for all U.S. Installations.

5. Use this column for all Canadian Installations.

T. FUEL OIL COMBUSTION

ADJUSTMENT

After operating for a sufficient period of time to assure a

warm boiler, adjustments should be made to obtain efficient

combustion.

Burner efficiency is measured by the amount or percentage of

O

2

present in the flue gas. O

2

readings determine the total

amount or excess air in the combustion process, above the

point of stoichiometric combustion or perfect combustion.

Stoichiometric combustion however, is the reference point

used when setting fuel/air ratios in a boiler.

There must always be excess air in the combustion process to

account for changes in boiler room conditions and to ensure

the combustion is on the proper side of the combustion curve .

Proper setting of the air/fuel ratios at all rates of firing must

be established by the use of a combustion gas analyzer.

Efficient combustion cannot be solely judged by flame

condition or color, although they may be used in making

approximate settings. Combustion settings should be done so

that there is a bright sharp flame with no visible haze.

Most flue gas analyzers in use today measure the content, by

percentage, of oxygen (O

2

) and in some cases, smoke.

Carbon dioxide (CO

2

) is not normally measured with modern

gas analyzers, but may be displayed as a calculation.

The O

2

levels through the entire firing range of the burner,

low fire to high fire should be tested. Cleaver-Brooks

recommendations on turndown should also be followed and

the turndown range of the burner should not be exceeded.

It is required to set the burner to operate with a reasonable

amount of excess air to compensate for minor variations in

the pressure, temperature, or burning properties of oil. Fifteen

to 20% excess air is considered reasonable. This would result

in an O

2

reading of 3% to 4%, at high fire.

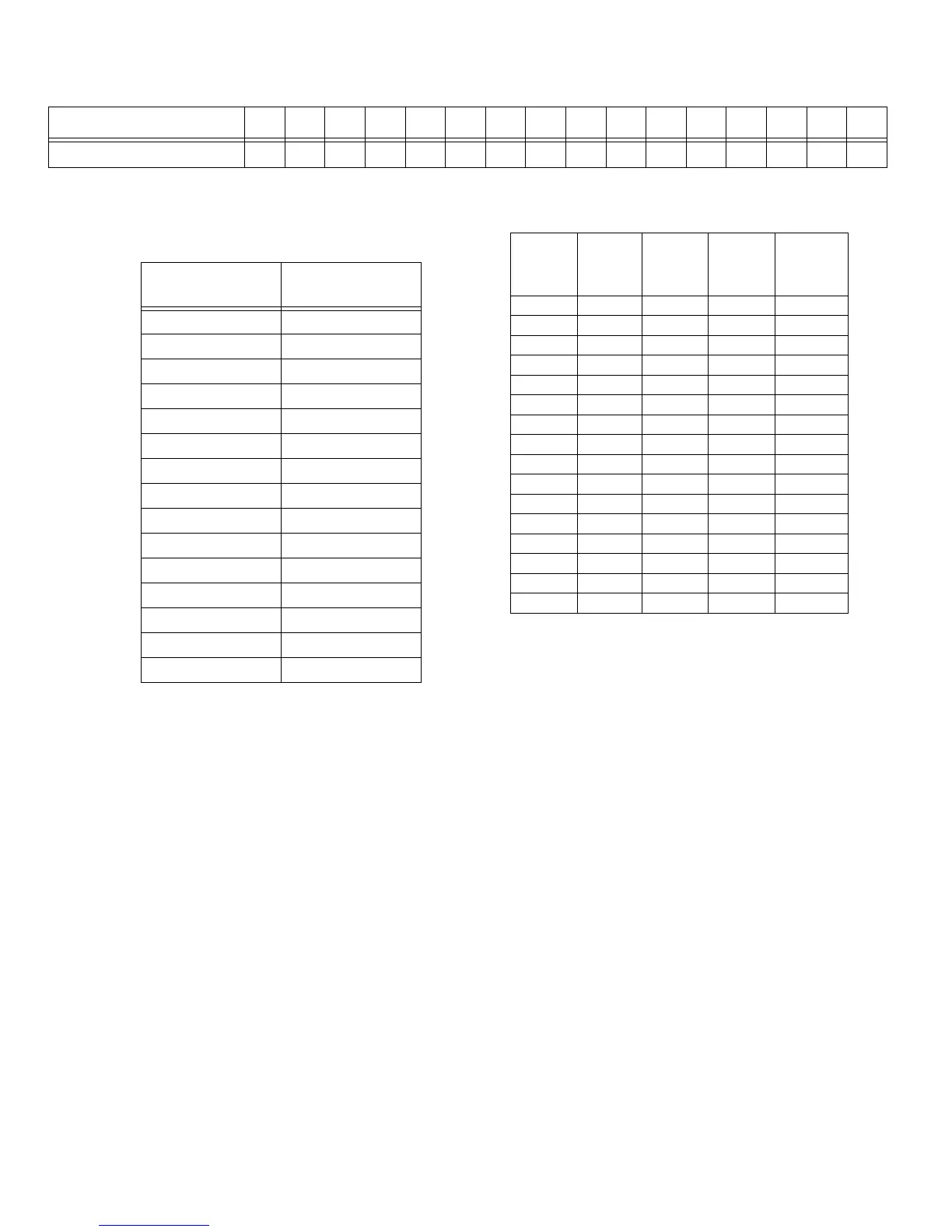

REGULATOR INLET

PRESSURE (PSIG)

PRESSURE FACTOR

11.05

21.11

31.18

41.25

51.32

61.39

71.45

81.53

91.59

10 1.66

11 1.72

12 1.81

13 1.86

14 1.93

15 2.00

Table 6-2: Pressure Correction Factors

MODEL NO. 150 200 250 300 350 400 450 500 550 600 700 800 900 1000 1100 1200

Fuel Consumption Gas (cfh)

A

1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 7000 8000 9000 10000 11000 12000

A. Natural Gas @ 1000 Btu/cu-ft.

Table 6-1: Fuel Consumption (Natural Gas)

Table 6-3: Minimum Required Gas Pressures

Loading...

Loading...