GENERAL DESCRIPTION Chapter 1

750-177 1-3

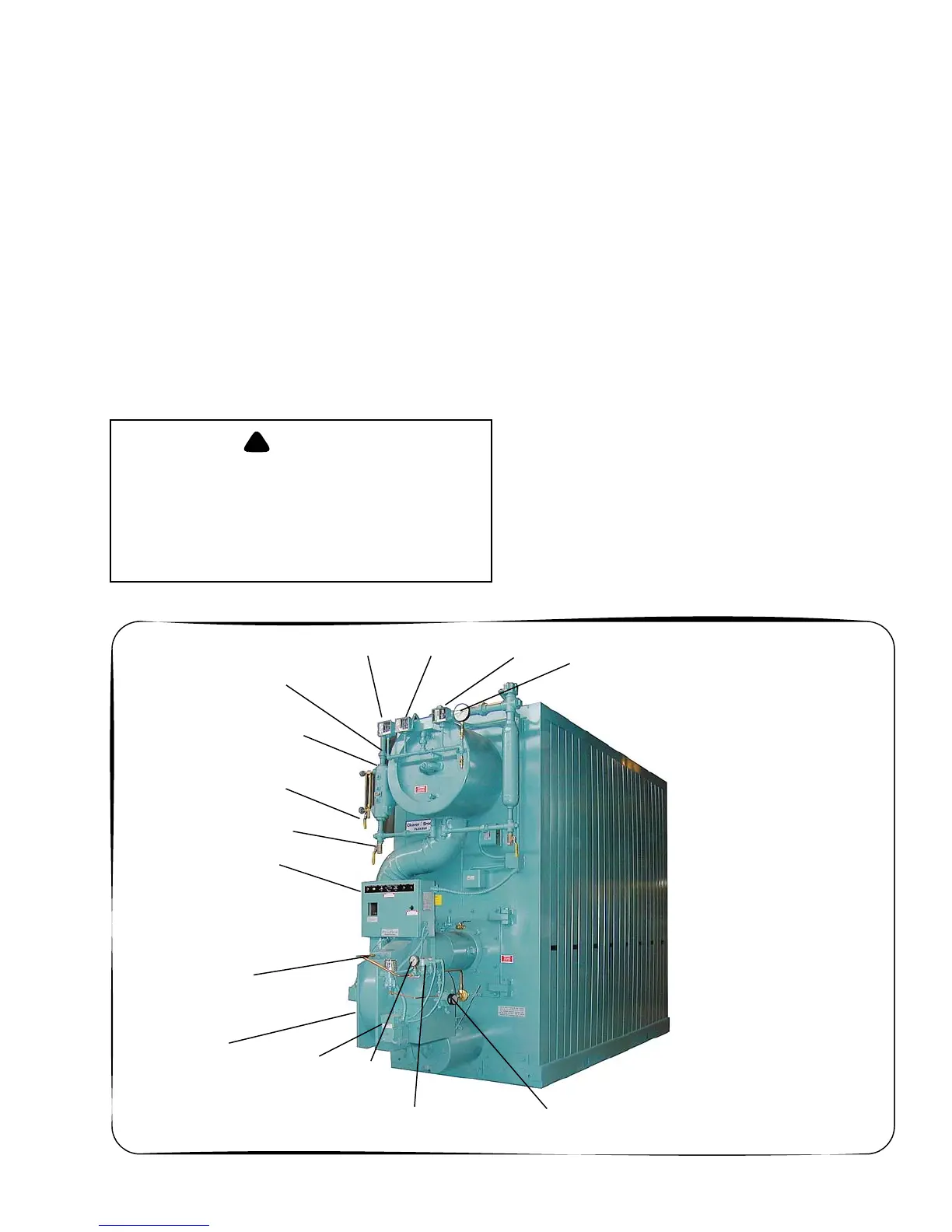

3. Modulating Limit Pressure Control (Figure 1-2 and 1-3):

Senses changing boiler pressures and transmits the

information to the modulating motor to change the

burner firing rate when the manual-automatic switch is

set on “automatic.”

4. Low Water Cutoff and Pump Control (Figure 1-2, 1-4

and 1-5): Float-operated control responds to the water

level in the boiler. It performs two distinct functions:

•Stops firing of the burner if water level lowers below the

safe operating point. Energizes the low-water light in the

control panel; also causes low-water alarm bell (optional

equipment) to ring. Code requirements of some models

require a manual reset type of low-water cutoff.

•Starts and stops the feedwater pump (if used) to maintain

water at the proper operating level.

!

DANGER

CAUTION

Determine that the main and auxiliary low

water cutoffs and pump control are level af-

ter installation and throughout the equip-

ment’s operating life. Failure to follow these

instructions could result in equipment dam-

age.

5. Water Column Assembly (Figure 1-2): Houses the low-

water cutoff and pump control and includes the water

gauge glass, gauge glass shutoff cocks.

6. Water Column Drain Valve (Figure 1-2): Provided so

that the water column and its piping can be flushed

regularly to assist in maintaining cross-connecting

piping and in keeping the float bowl clean and free of

sediment. A similar drain valve is furnished with

auxiliary low-water cutoff for the same purpose.

7. Gauge Glass Drain Valve (Figure 1-2): Provided to flush

the gauge glass.

8. Safety Valve(s) (Figure 1-6 and 1-8): Prevent buildup

over the design pressure of the pressure vessel. The size,

rating and number of valves on a boiler is determined by

the ASME Boiler Code. The safety valves and the

discharge piping are to be installed to conform to the

ASME code requirements. The installation of a valve is

of primary importance to its service life. A valve must be

mounted in a vertical position so that discharge piping

and code-required drains can be properly piped to

prevent buildup of back pressure and accumulation of

foreign material around the valve seat area. Apply only a

moderate amount of pipe compound to male threads and

Figure 1-2: Typical Steam Boiler - Light Oil Fired

WATER COLUMN

GAUGE GLASS

DRAIN VALVE

LOW WATER CUTOFF

AND PUMP CONTROL

CONTROL PANEL

FORCED DRAFT

FAN MOTOR

FLAME

DETECTOR

MODULATING

MOTOR

OIL SOLENOID

VALVES

OIL SUPPLY

PRESSURE

GAUGE

HIGH LIMIT

PRESSURE

MODULATING LIMIT

PRESSURE

CONTROLCONTROL

OPERATING LIMIT

PRESSURE

CONTROL

STEAM PRESSURE

GAUGE

WATER COLUMN

DRAIN VALVE

OIL PUMP

Loading...

Loading...