8 PL12EN-1001 2011-01 en01d441_bedingt.fm, 07.04.2011

Set-Up Guide

1

• Location of printer

• Attachment of a data collection unit, if desired.

• Attachment of remote annunciators, socket nest, or remote parameter select.

• Attachment of the unit in a network to a computer.

• Operation convenience/safety – keep cables off the floor or dangling in operator areas.

1.5.3 Power source

The controller requires a power supply connection of:

• 104–126 VAC or 207– 253 VAC / 50–60 Hz single phase / 1A Input current (rated), 16A (peak)

1.5.4 Intended use

The mPro400GC may be used only under the following conditions:

• Industrial EMC limit value class A

• Only cables of type authorized by DGD may be used.

• Only accessory parts authorized by DGD may be used.

• Unauthorized alterations, repairs and modifications are prohibited for reasons of safety and product lia-

bility.

1.5.5 EMC measures

• The filters required to satisfy the EMC regulations are built into the unit.

• The sealed control cabinet and shielded cable provide very good protection against irradiated and radi-

ated interference.

• The tool complies with the following applicable EMC standards:

- EN 61000-6-2:2005

- EN 55011:2007

- EN 61000-4-2:1995 + A1: 1998 + A2: 2001

- EN 61000-4-3:2006 + A1:2008

- EN 61000-4-4:2004

- EN 61000-4-5:2006

- EN 61000-4-6:2009

- EN 61000-4-8:1993 + A1: 2001

- EN 61000-4-11:2004

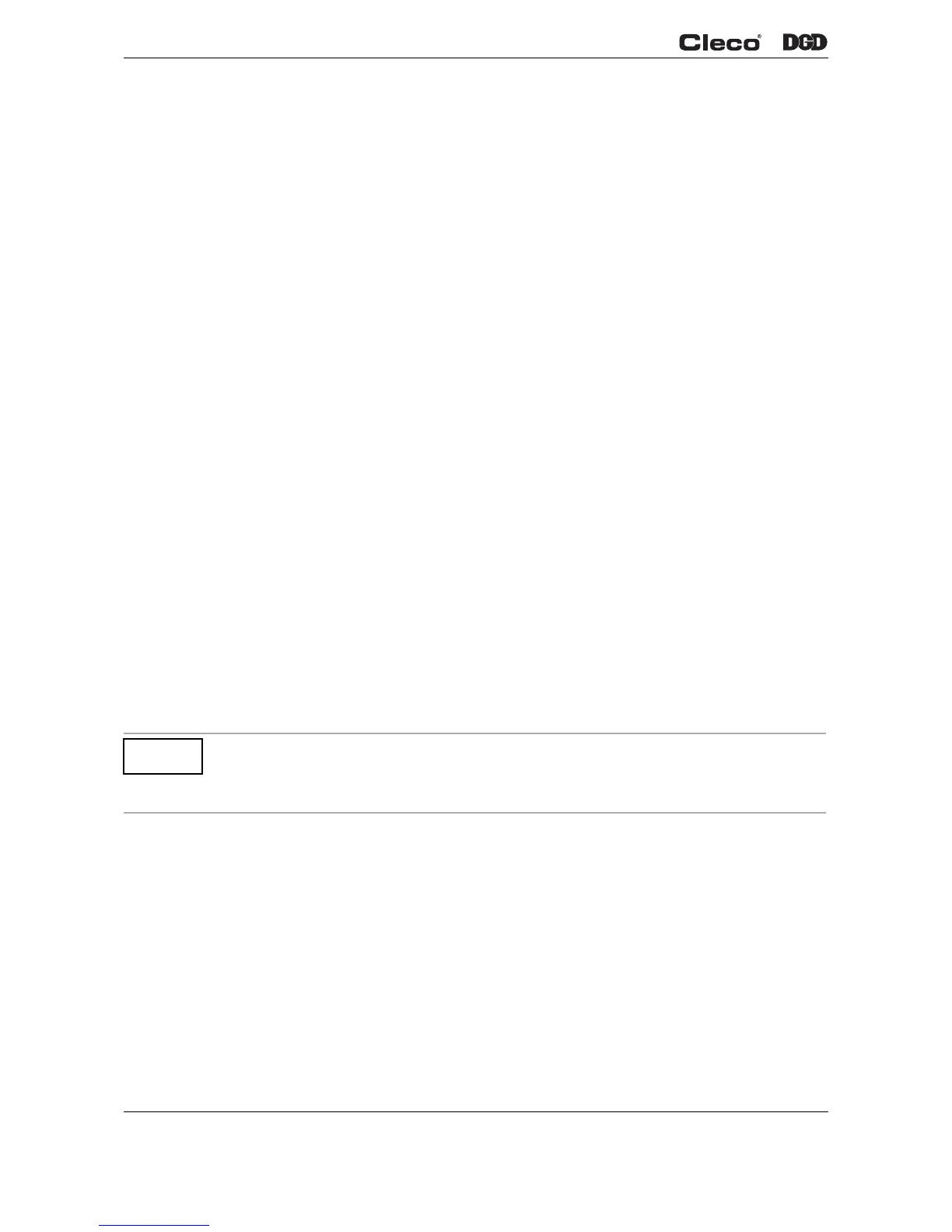

1.6 Mounting the Controller

1. Loosen the two long mounting screws at the bottom of the controller so the mounting plate can be

separated from the controller. See Fig. 2-2.

2. Fig. 2-3 illustrates the bolt pattern for hanging the mounting plate on a wall. Note the hole size dimen-

sions so the correct size bolts are chosen. Size ¼“ or M6 bolts (4) should fit the mounting plate holes

and support the controller.

3. Once the mounting plate is installed in its location the controller can be hung on the bracket utilizing

the four studs protruding from the back of the controller. Once in place, the controller can be secured

at the bottom using the two long screws removed in Step 1.

This is a Class A device. The device may cause signal interference; in this case, the operator may be

required to implement suitable EMC measures.

➔ It is prohibited to operate the unit unless the control cabinet is closed. The properties of the shielding

would change and the noise emission would increase.

ATTENTION!

Loading...

Loading...