97

climatemaster.com

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Packaged Units

Rev.: 1/06/09B

Functional Troubleshooting - S.I. Units

Note: Never connect refrigerant gauges during startup procedures. Conduct water-side analysis

using P/T ports to determine water fl ow and temperature difference. If water-side analysis shows

poor performance, refrigerant troubleshooting may be required. Connect refrigerant gauges as a

last resort.

Rev. 11/06

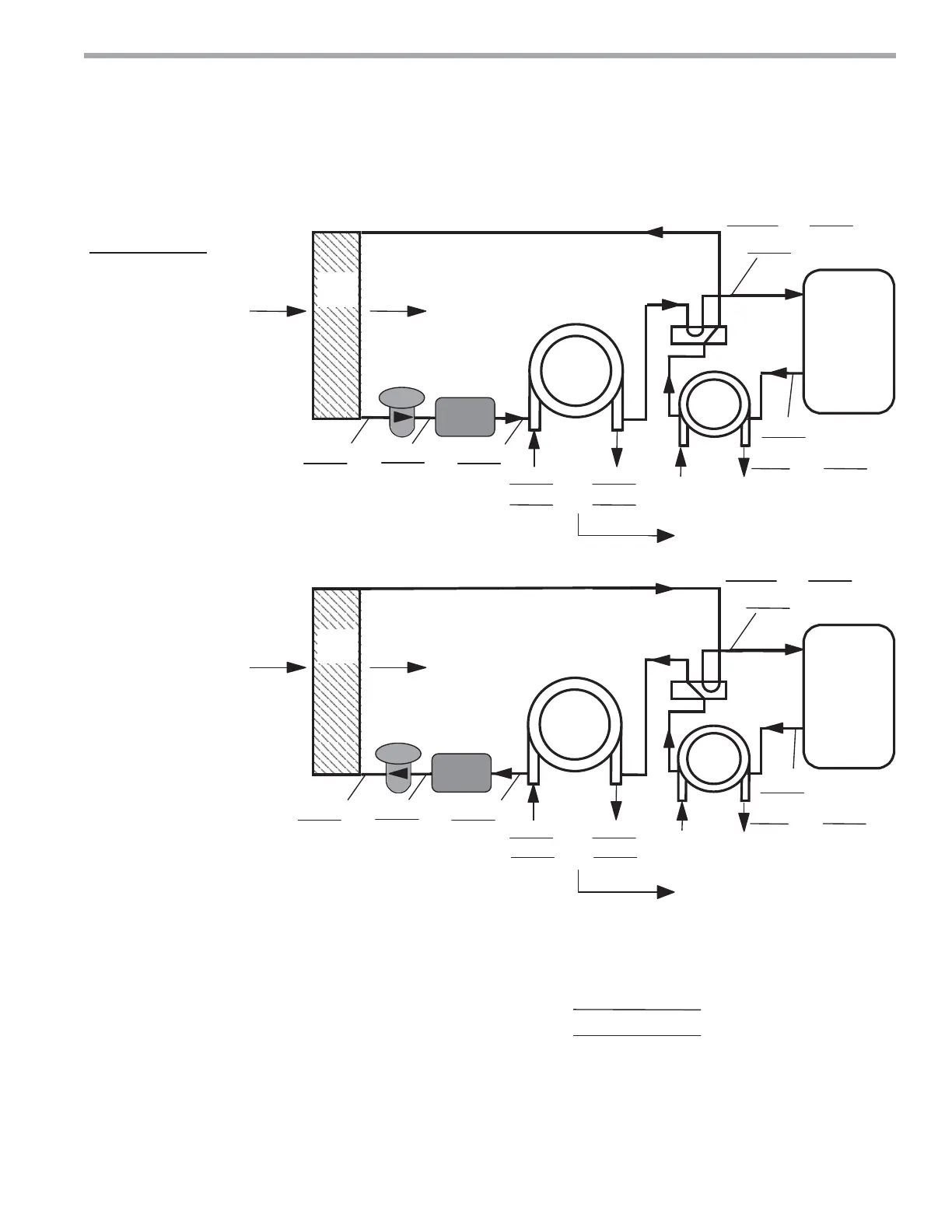

COAX

COMPRESSOR

DISCHARGE

SUCTION

HWG

COOLING CYCLE ANALYSIS -

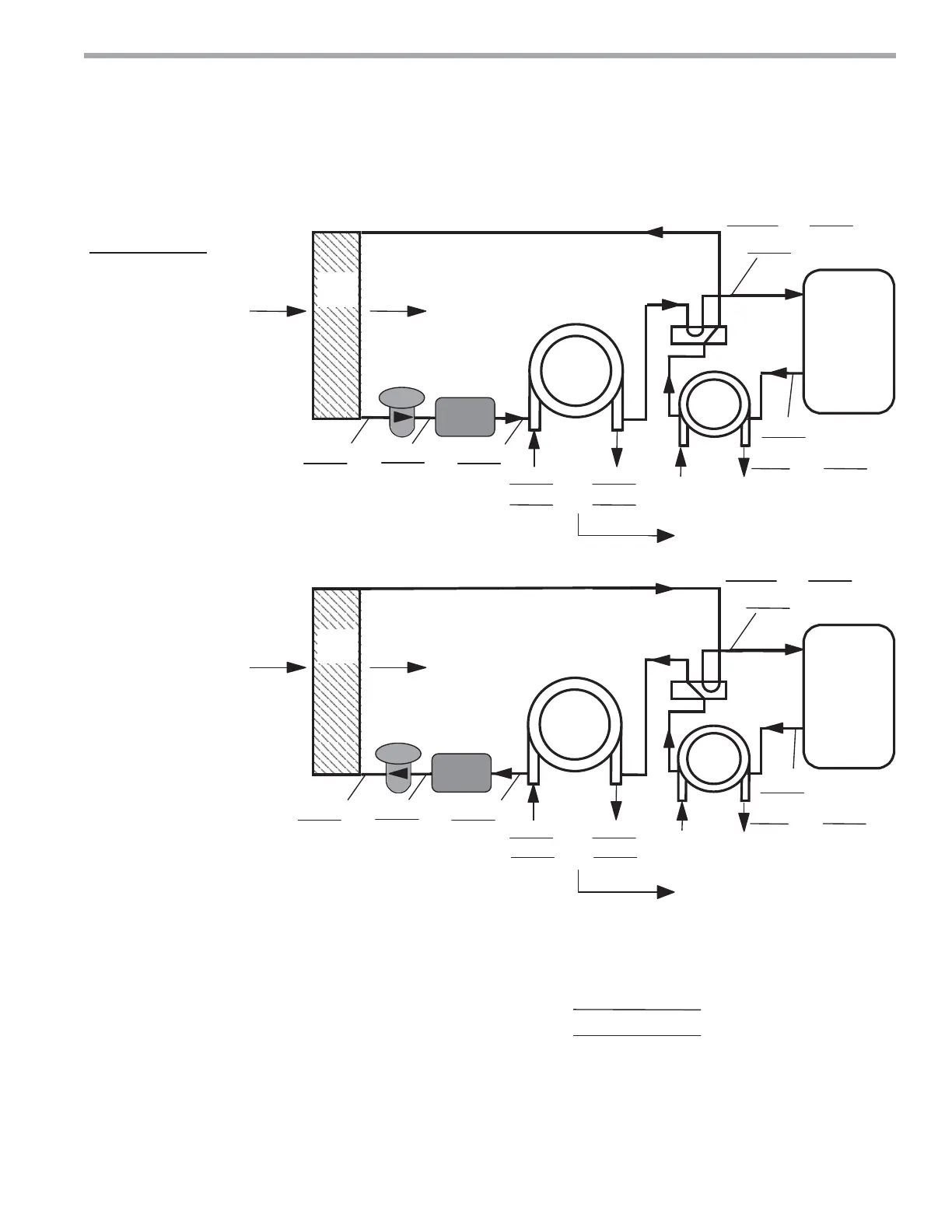

COAX

COMPRESSOR

DISCHARGE

SUCTION

HWG

HEATING CYCLE ANALYSIS -

bar

SAT

bar

SAT

C

C

AIR

COIL

CC

FP2: HEATING

LIQUID LINE

C

EXPANSION

VALVE

AIR

COIL

CC

bar

SAT

bar

SAT

C

C

CC

WATER IN WATER OUT

kPa kPa

CC

WATER IN WATER OUT

kPa kPa

Look up pressure drop in

I.O.M. or spec. catalog to

determine flow rate.

Look up pressure drop in

I.O.M. or spec. catalog to

determine flow rate.

†

Use 4.18 for water, 4.05 for antifreeze

FILTER

DRIER*

FLASH

GAS LINE

C

FP1

SENSOR

C

EXPANSION

VALVE

FILTER

DRIER*

FP2: FLASH

GAS LINE

C

OTHER SIDE

OF FILTR DR

C

FP1: CLG

LIQ LINE

C

*Filter drier not on some units with R22 refrigerant.

Refrigerant Type:

R410A

R22

R407C

Heat of Extraction (Absorption) or Heat of Rejection =

________flow rate ( diff. ( factor = _____________

(kW)

Superheat

Subcooling

Suction temperature - suction saturation temp.

Discharge saturation temp. - liquid line temp.

=

=

=

=

(deg C)

(deg C)

l/s) x _________ temp. deg. C) x ________ fluid

†

Voltage: ________

Comp Amps: _______

Total Amps: ________

˚

˚

˚

˚

˚

˚

˚

˚

˚

˚

˚˚˚

˚

˚

˚

˚

˚

Loading...

Loading...