35

5 - ELECTRICAL CONNECTIONS

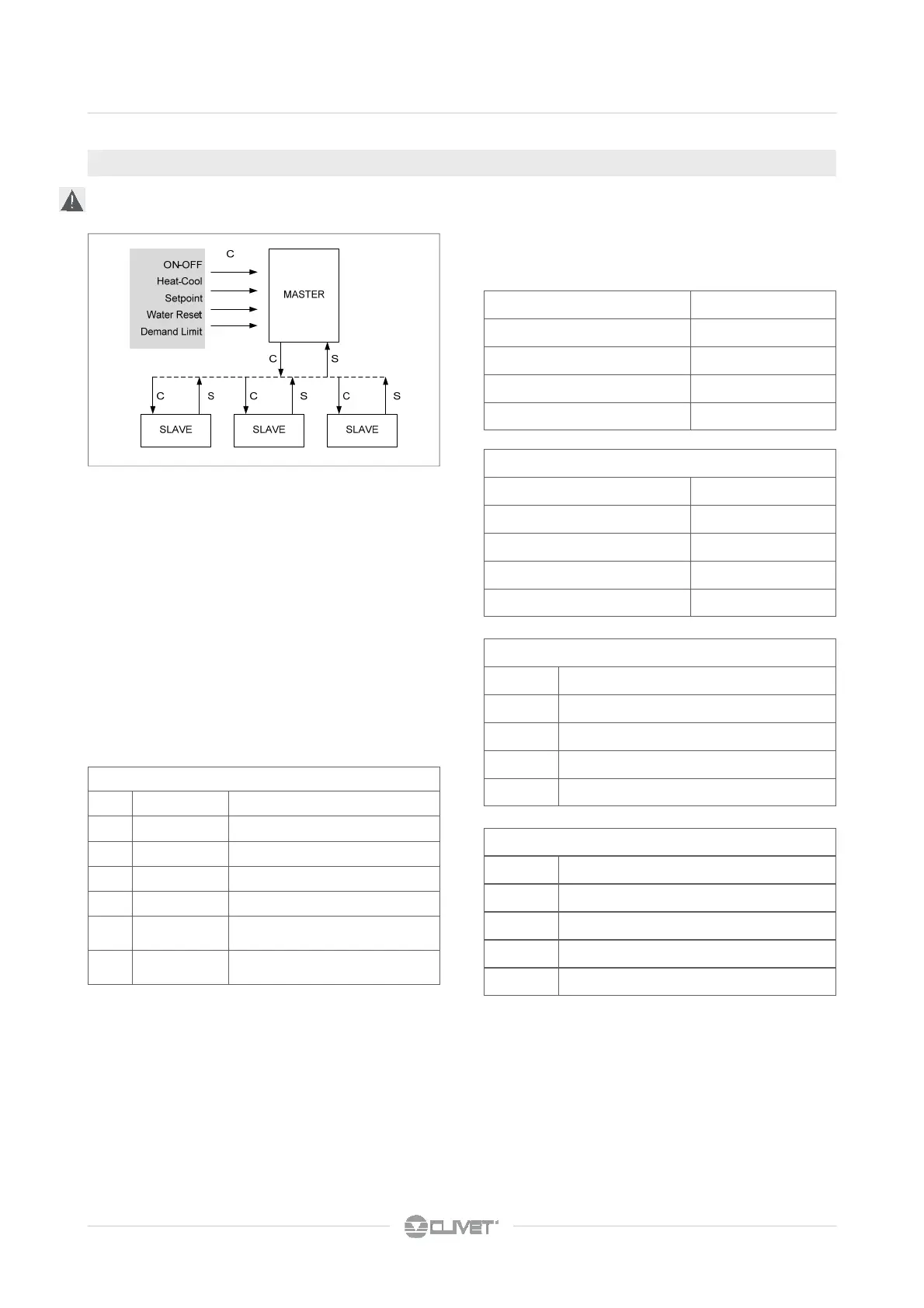

5.29 MASTER SLAVE

1. max : 1 master + 5 slave

2. Perform the electrical connections as indicated in the

diagram

3. OFF unit

4. Set the DIP1 and DIP4 on the master unit, as indicated in

the diagram

5. Set the DIP1 and DIP4 on the slave units, as indicated in

the diagram

6. Switch on the master and slave

7. Set the parameters on the master unit

C controls

S signaling

Unit Total hours

Address1 13536

Address 2 12456

Address 3 14234

Address 4 13765

Unit Total hours

Address 2 12456

Address1 13536

Address 4 13765

Address 3 14234

Unit ranking based on hours of operation

Master unit configuration parameters *

306 NumberMachine N. of units connected in Mininet

308 NumSleep N. of units in standby for rotation

309 ControlAlarm Enables the exclusion of the unit in alarm

310 OffsetMS Offset between the unit SetPoint

313 TimeAlarm Alarm duration before the standby

314 TimerUnitMS Sturt-up delay of 1°capacity step of each

unit in mininet

317 ACSSleepMode Enabling (only) DHW when the unit is in

Sleep

Example:

4 unit

OffsetMS: value of the offset between the setpoint = 1,5 °C

Unit setpoint

Address 2 SetCool = 6,5 °C

Address1 SetCool + Offset = 8,0 °C

Address 4 SetCool + (2xOffset) = 9,5 °C

Address 3 SetCool + (3xOffset) = 11,0 °C

Cool operation

Unit setpoint

Address 2 SetHeat = 45,0 °C

Address1 SetHeat - Offset = 43,5 °C

Address 4 SetHeat - (2xOffset) = 42,0 °C

Address 3 SetHeat - (3xOffset) = 40,5 °C

Heat operation

* Parameters accessible through the installer password 115).

The access by pwd is reserved to qualified personnel;

The parameters changes may cause malfunctions.

The function is not compatible with the boiler option.

Loading...

Loading...