19

Starter/Generator

GASOLINEVEHICLE-ELECTRICAL

COMPONENTS

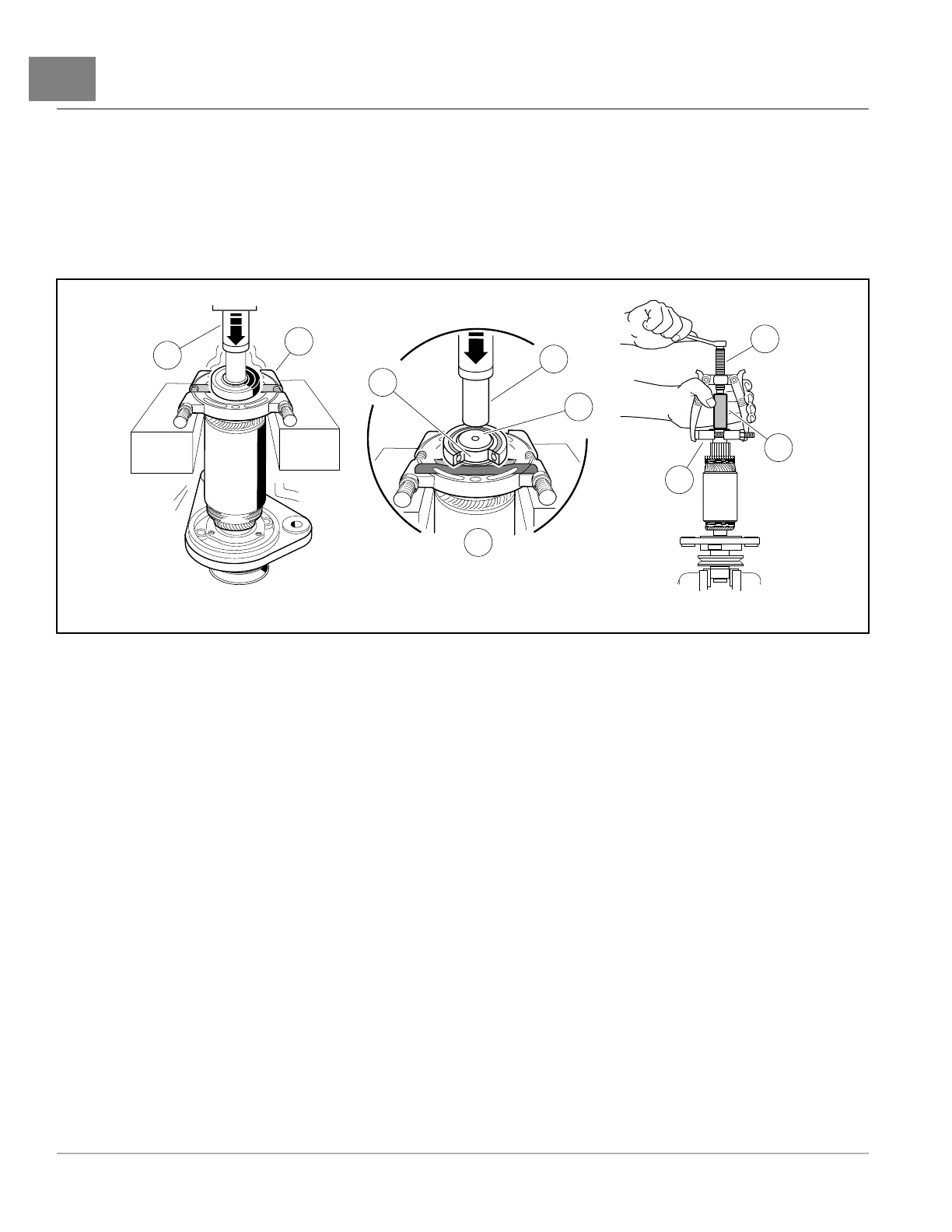

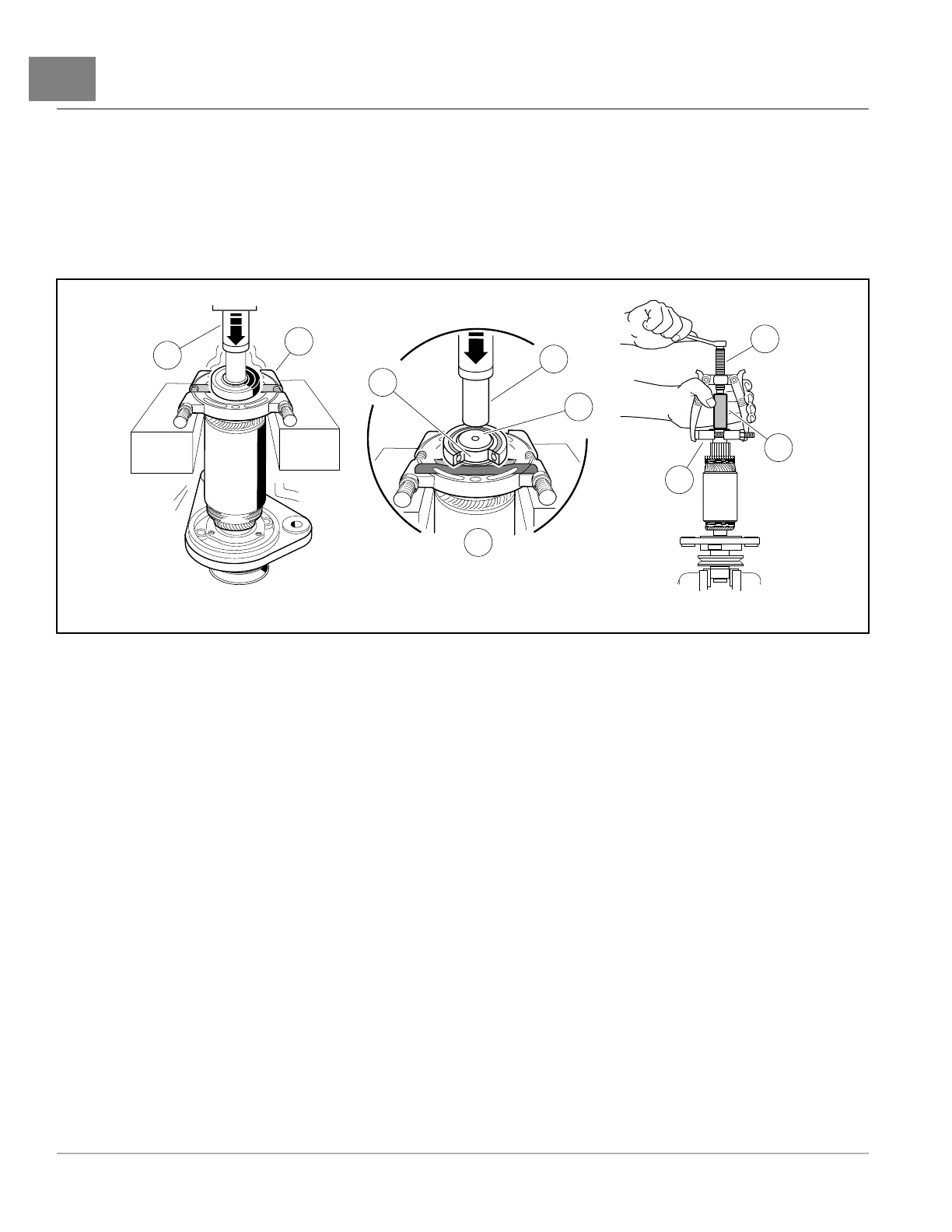

BEARINGREMOVAL

1.Placethewedgeattachmenttoolbetweenthebearingandthearmature.Makesurethewedgeattachmenttool

issupportingtheinnerraceofthebearing.Ifapressisnotavailable,secureabearingpullertothewedge

attachmenttoolandpullthebearingoffoftheendofthearmatureshaft.Supportthearmaturesothatitwillnot

dropwhenthebearingisremoved(Figure19-8,Page19-6).

2.Slidethebearingretainerring(32)offoftheoutputendoftheshaft(Figure19-6,Page19-5).

1.PressRam2.WedgeAttachmentT ool3.Bearingsectionedforclarity4.Supportinnerraceofbearing5.Usea1/2inchsocketorpipe6.

Pressagainstarmatureshaft7.Usebearingpullerifapressisnotavailable

494

Figure19-8BearingRemoval

FIELDCOILASSEMBLY

Replaceentireeldcoilhousingassemblyifcoils,poleshoesorterminalsaredamaged.(Figure19-9,Page19-7).

VISUALINSPECTIONOFARMATURE

Obviousdefectscanbeseenbyexaminingthearmature.Ifanarmaturehasfrayedorcharredinsulation,brokenwires

orthrownsolder,itisobviouswithouttestingthatitshouldbereplaced.Faultsseenduringthevisualinspectioncanaid

indiagnosingtheoriginalcauseofthefailure.Itemstolookforarelistedbelow.

•Burned,charred,orcrackedinsulation

•Improperlycuredvarnish

•Thrownsolder

•Flaredarmaturewindings

•Worn,burned,orglazedcommutator

•Looseorraisedcommutatorbars

•Bruisedordamagedarmaturecorelaminations

•Wornarmaturebearingorshaft

•Dirtyoroilycommutator

Page19-62019PrecedentVillager2MaintenanceandServiceManual

Loading...

Loading...