IS-NT-Async-SPI, SW Version 1.2, ©ComAp – February 2011

IS-NT-Async-SPI-1.2.PDF

78

GCB open del [ s ] (FV)

The timeout to unload the gen-set. Should the load ramp fail to bring the gen-set power down to GCB open

level to allow the opening of GCB, the breaker will open after GCB open del.

Step: 1 s

Range: Load ramp – 1800 s

Force value possibility: Yes

GCB close TOut [s]

Maximum allowed time for RPM matching procedure.

Step: 1 s

Range: 1 – 1800 s, NO TIMEOUT

RPM matching /load control adjustment

Hint:

Use isochronous speed governor.

Two wire shielded connection from controller SPEED GOVERNOR output (SG OUT, SG COM) to Speed

governor auxiliary input is recommended.

A full range change of the IS speed governor output (from –10V to 10V) should cause 5-10% change of the

engine speed (-10V ~ 95% RPM

nom

, 0V ~ 100% RPM

nom

, +10V ~ 105% RPM

nom

IMPORTATNT

Speed governor has to be adjusted for optimum performance before controller RPM match / load

control adjusting.

Check generator phase sequence before the first GCB connection.

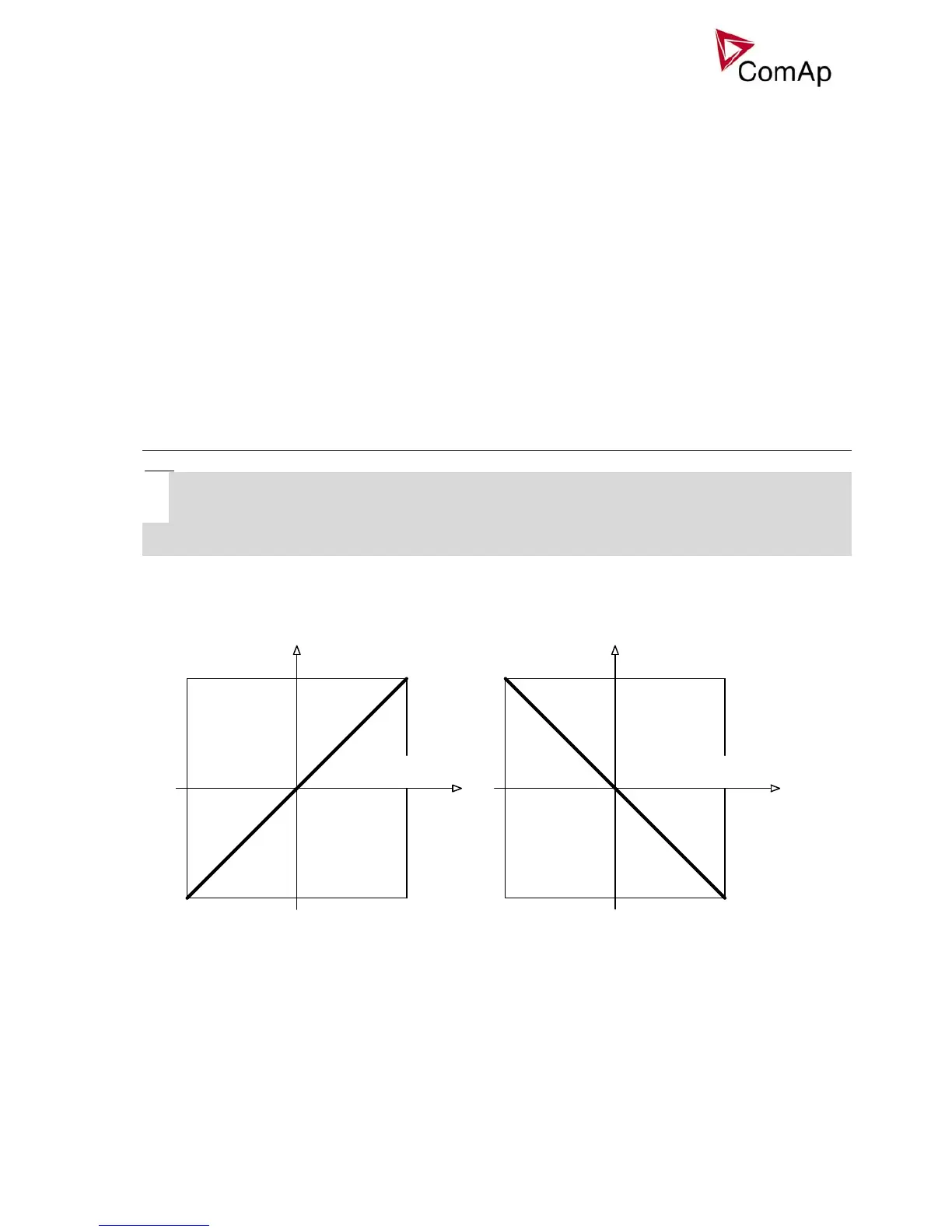

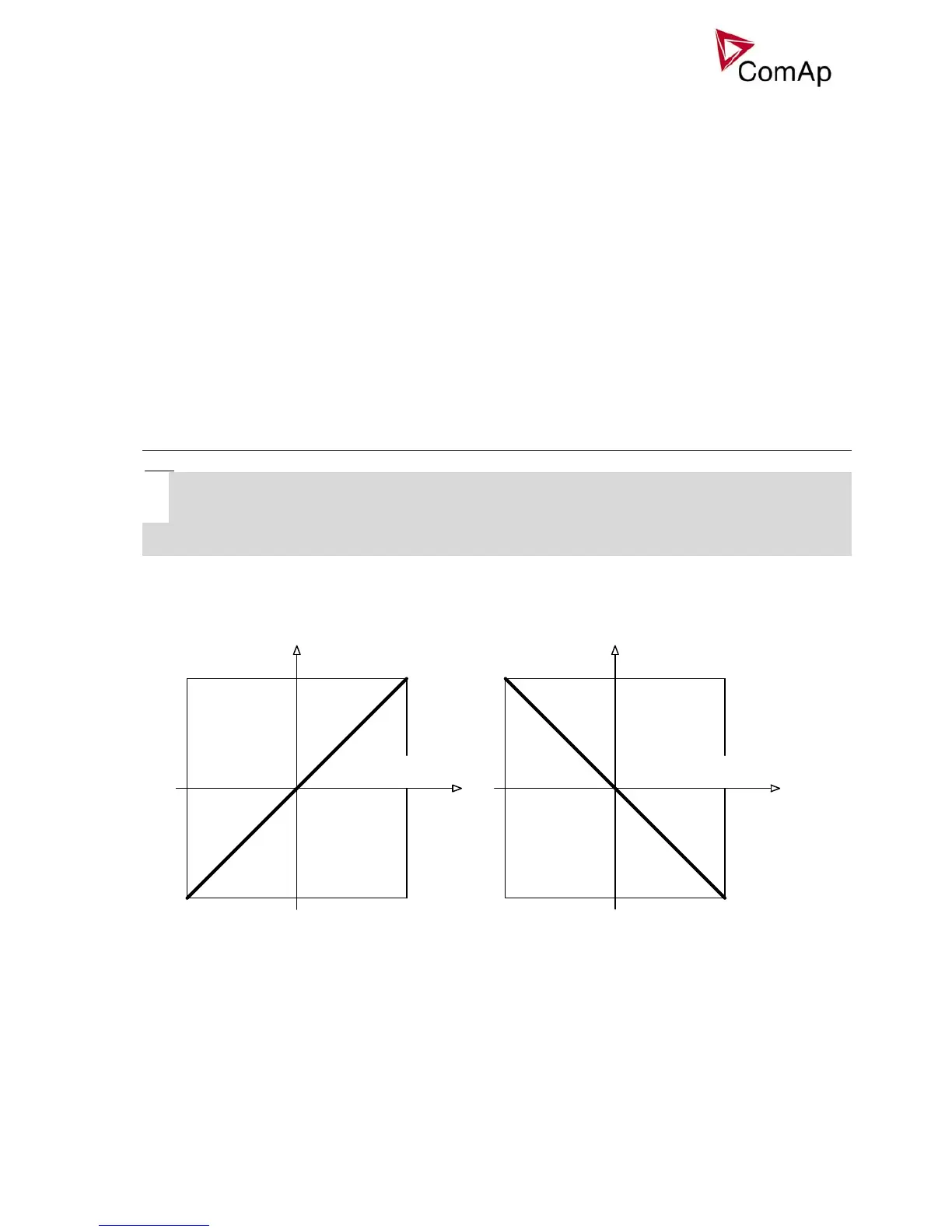

RPMRPM

Volt [V] Volt [V]

0 V

+10 V- 10 V

Speed governor

voltage output1500

50

1575 RPM

52.5 Hz

1425 RPM

47,5 Hz

0 V

- 10 V

1500

50

1575 RPM

52.5 Hz

1425 RPM

47,5 Hz

+10 V

Speed governor

voltage output

+ 2.5 % of nominal+ 2.5 % of nominal

- 2.5 % of nominal - 2.5 % of nominal

SpeedRegChar = POSITIVE SpeedRegChar = NEGATIVE

Before optimalization of RPM/Load ctrl setpoint group adjusting disconnect GCB OPEN/CLOSE output or

set RPM matching = 0 to avoid paralleling.

RPM matching adjustment

1) Start the engine in MAN Mode.

2) Set the engine RPM by speed trim on speed governor or by Speed gov bias and SpeedGovLowLim

to Nominal frequency.

Loading...

Loading...