9. Service and maintenance

46

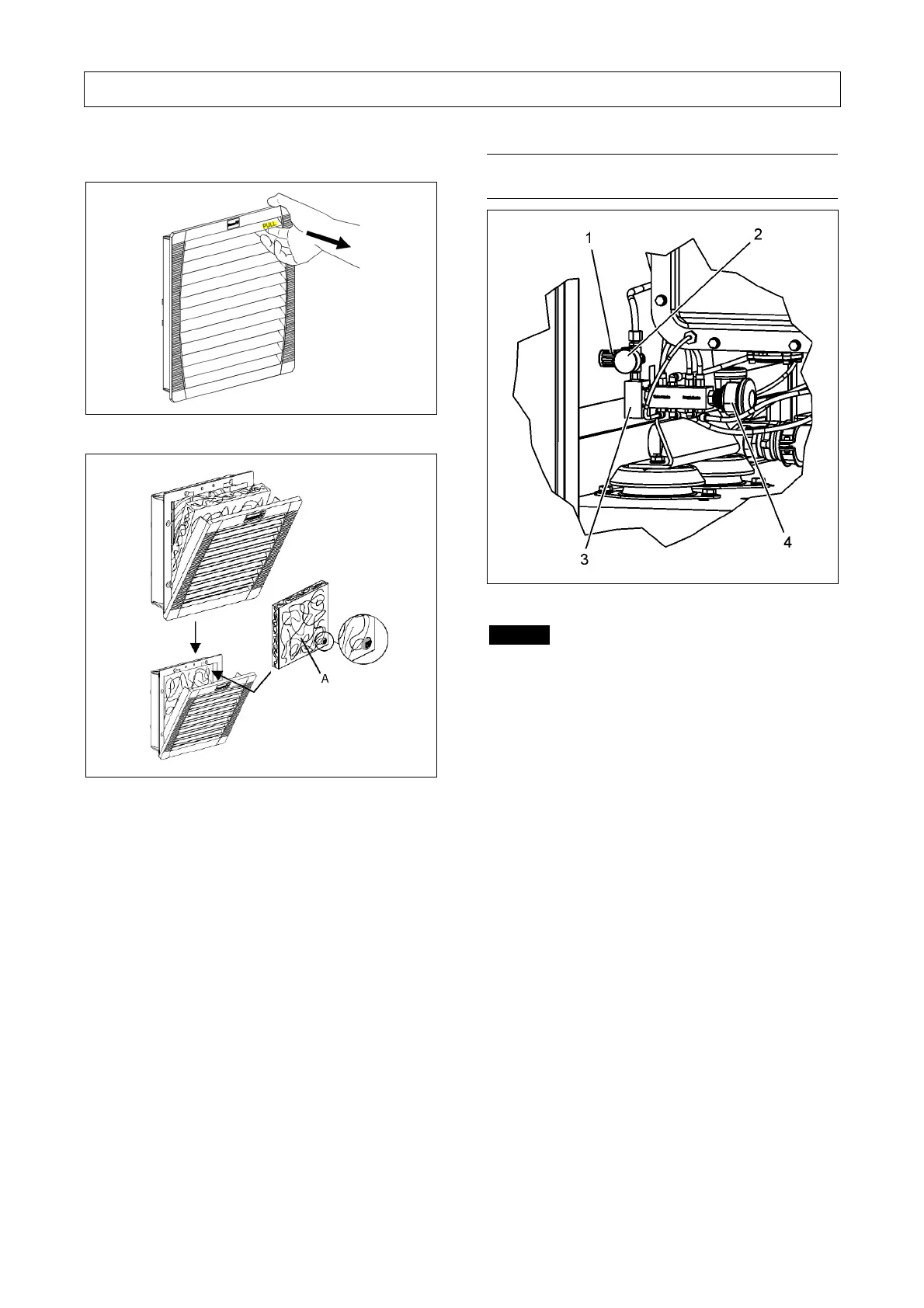

b) Control-cabinet inlet filter (-4- Fig. 25)

Fig. 26

Fig. 27

Perform filter mat change as follows:

• Open the louvred grilles of the inlet filter (Fig. 26).

• Remove the filter pad.

• Insert the new filter pad into the louvred grille.

Ensure that the smooth side (-A- Fig. 27) of the filter

pad faces the air inlet side.

• Place the louvred grille back onto the filter housing.

Changing times for the filter mat

The operating modes and the quality of the suctioned

air (e.g. dust content) has a strong influence on the filter

service life.

The filter should be checked on a weekly basis,

eventually daily basis, for dust build-up.

In these operational cases, shorter change intervals are

possible.

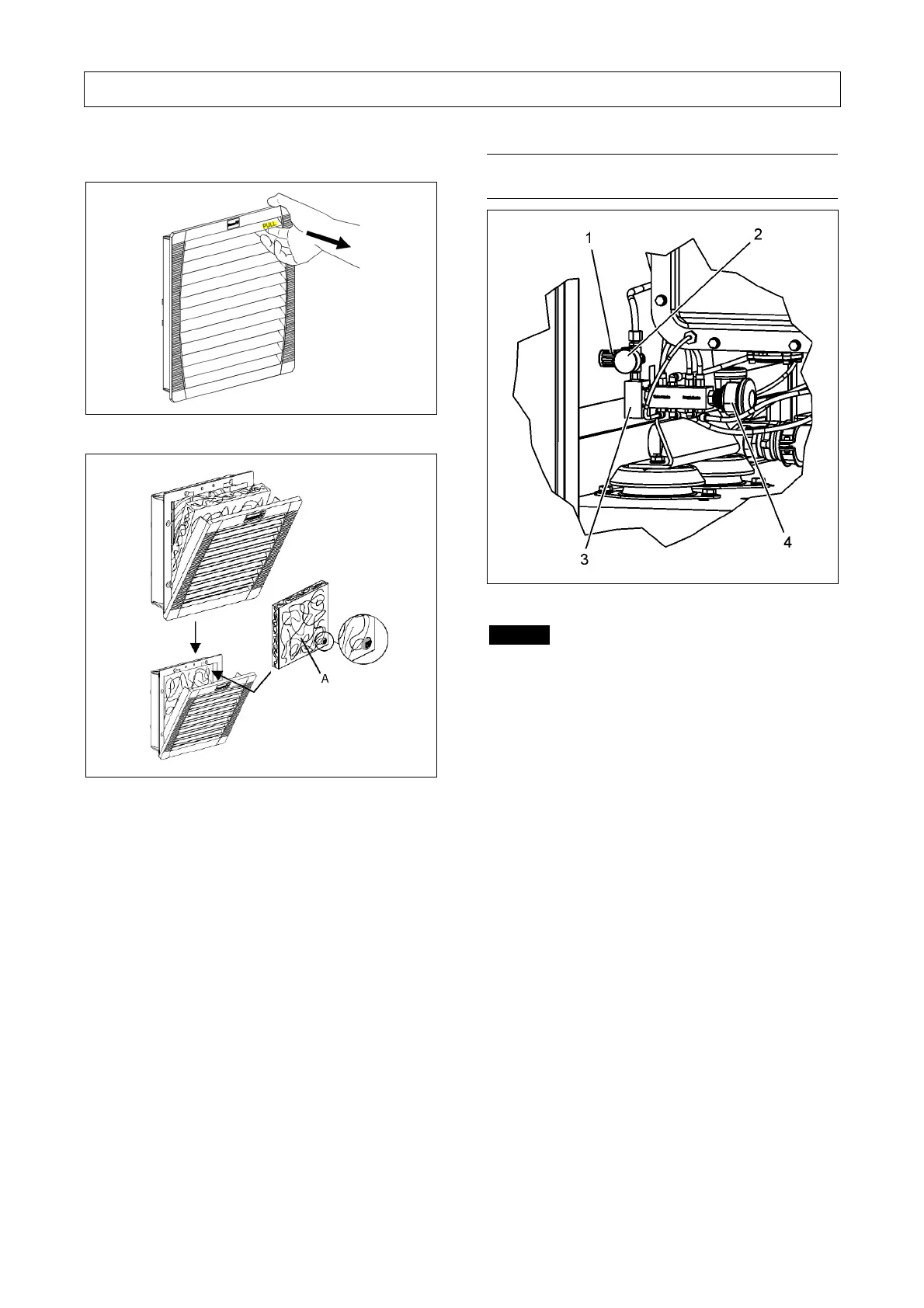

9.13 Cleaning of the bearing flushing

system

Fig. 28

Danger

Only ever clean the blow-off silencer and ejector

nozzle with the compressor stopped and

depressurized..

• Check the blow-off silencer (-1+2- Fig. 28) and

ejector nozzle (-3- Fig. 28) for fouling.

• Clean or replace if severely fouled.

• The blow-off silencer must be replaced in

accordance with the data in Section 9.3 at the latest,

however.

Loading...

Loading...