28

K09657H02 | PROC-CAL/002/03 USER MANUAL | V. 11/07/2023

. MAINTENANCE

From that point, if your grinder is an E5 keep

following the next the steps until 12.3.5. if not

skip until the point 12.3.6.

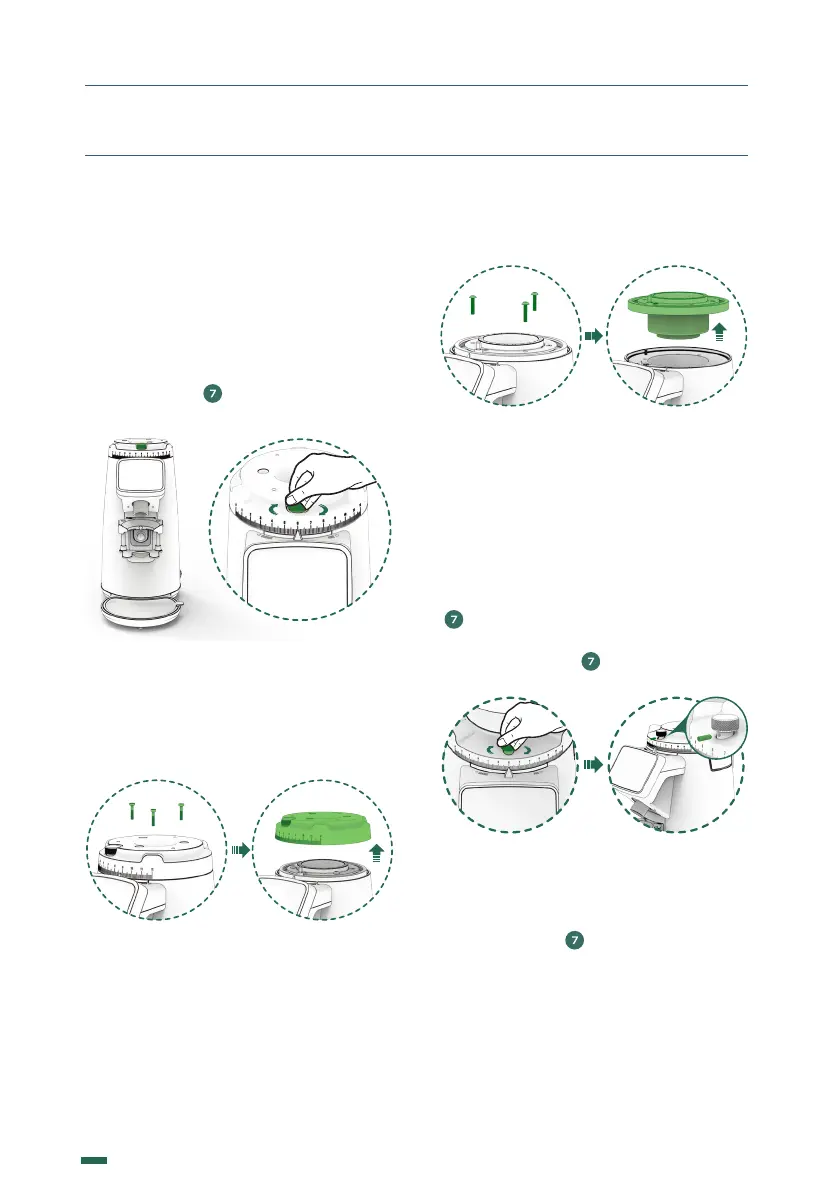

12.3.3. To avoid losing the position of the

regulator scale with respect to the current

grinding point, it is essential to tighten the

setting of the grinding regulator using the

adjusting brake ( ) by turning it clockwise

(Fig. 3).

Fig. 3

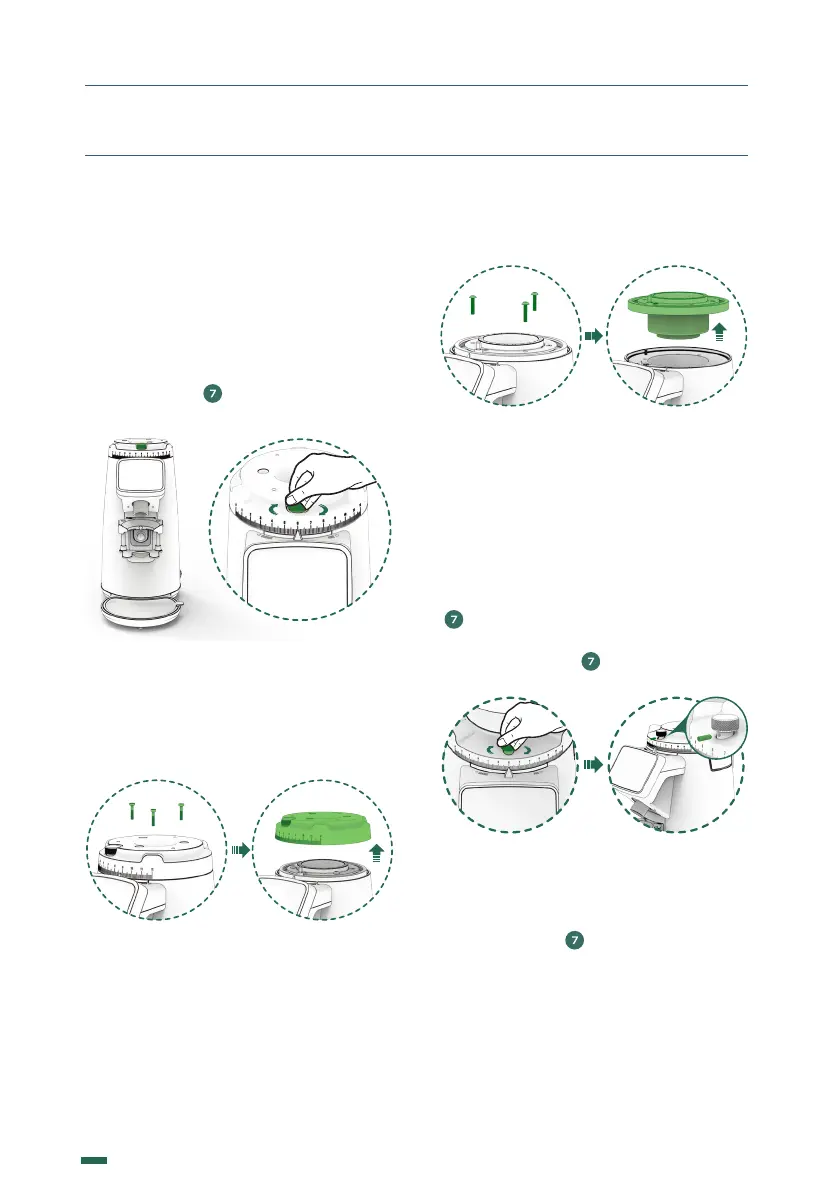

12.3.4. Loosen the grinding regulator screws

using an #3 Hex Allen key, according to

(Fig.4). Remove the regulator by pulling up.

(Fig.5).

Fig. 4 Fig. 5

12.3.5. Loosen the upper burrs support

screws using a #3 Hex Allen key, according

to (Fig.6). Remove the upper holder by

pulling upwards to access the grinding cavity,

clean the interior with the help of a brush

or vacuum cleaner and remove any coee

residue from the grinding cavity (Fig.7).

Fig. 6 Fig. 7

12.3.6. From this point, if your grinder has

Lock Load System skip until the point

12.3.11. if not, keep following the next steps.

To avoid losing the position of the regulator

scale with respect to the current grinding

point, it is essential to tighten the setting of the

grinding regulator using the adjusting brake

( ) by turning it clockwise (Fig. 8). Remove

the screw with a #2 Hex Allen key located in

the adjusting brake ( ). (Fig. 9).

Fig. 8 Fig. 9

12.3.7. Remove the regulation brake by

pulling upwards ( ) (Fig. 10). Loosen the

grinding regulator screws using a #3 Hex

Allen key, according to (Fig. 11).

Loading...

Loading...