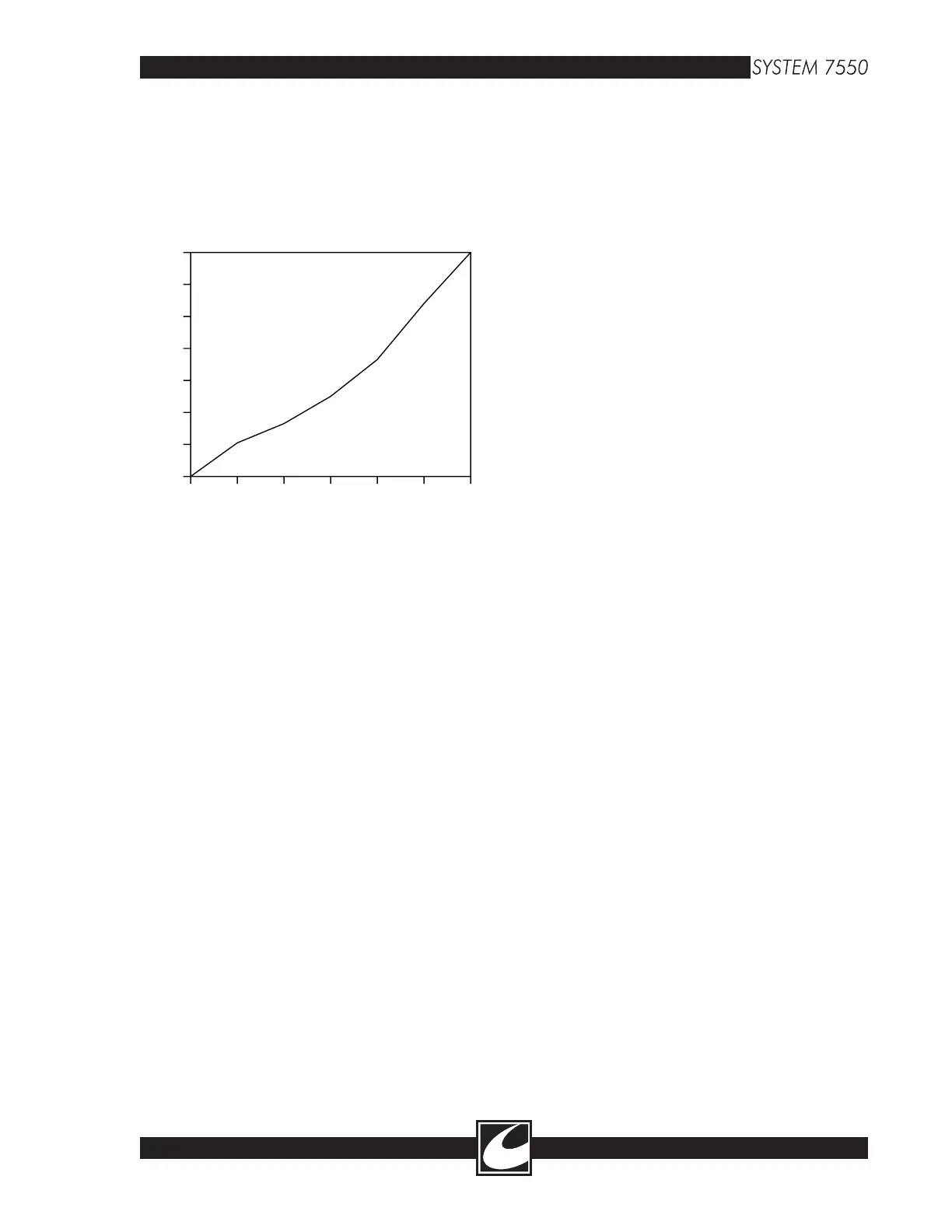

150

130

110

90

70

50

30

10

2

4

6

8

RESISTANCE (OHMS)

RESISTANCE BARS

Figure 6.4 Resistance vs. Bargraph

6-19

a drive time that occurs on the diode of U6. A

logic device on the Display Assembly drives this

diode with a square wave, and when this diode is

conducting current, and if ABC™ is requested ,

then both U8 and U9 will be switched on and the

collectors of both will go low.

mizing the RF voltage appearing across T4 wind

-

ings. T4 also acts to step-up the return imped

-

ance by about 10:1.

The A.R.M. oscillator generates a low power sin

-

ewave voltage of about 36 KHz. This frequency

is determined by the inductance of T2 in paral

-

lel with C25, and that of C27 and C30 reflected

through T4. Transistors Q2 and Q3 are cross

coupled via R28 and R32, so that when one tran

-

sistor is conducting, the other is off due to lack of

base drive. The conducting transistor turns off at

the next zero crossing of the sinusoidal voltage on

the primary of T2. This allows its collector volt

-

age to rise and thus provide base current to the

other transistor to switch on. The collector volt

-

ages appear like half-wave rectified AC, with each

collector 180 degrees out of phase.

The A.R.M. oscillator is powered by a constant

0.5mA DC current driven from the V

ARM signal

line. This current feeds into the center tap of T2

primary. The voltage on the center tap is the aver

-

age of the two collector voltages, so it appears

as a full-wave rectified sinewave. Inductor L1

holds the current supplied to T2 constant regard

-

less of these voltage variations, while C18 serves

as a bypass to limit the noise conducted from the

VARM line to the amplifier, U1D.

Diode VR2 is a +1.235V regulator whose output

voltage appears across the 2.49K ohm resistor

R20, thus driving a constant current of 0.5mA in

the V

ARM line. The voltage at TP3 is a 2X VARM

as U1D is a 2X amplifier.

The ASSIST resistance indicator (bargraph) will

be illuminated when the pad resistance is 10 to

150 ohms. At just over 10 ohms, the two left

segments are illuminated. As V

ARM increases,

additional segments illuminate in proportion to

VARM, progressing to the right until the resistance

approaches 150 ohms, where eight bars are illumi

-

nated. When the resistance exceeds 150 ohms, all

ten segments are illuminated.

In Dual Foil Mode, the microprocessor declares a

Return Fault if the resistance is less than 10 ohms

or greater than 150 ohms. If V

ARM is within

acceptable limits (10 - 150 ohms), the Return

Fault Indicator will turn off when the Monitor

Set switch is pressed. A Return Fault is declared

when the resistance increases about 20% above

the stored value or goes out of range. When a

Return Fault condition occurs, and if the resis

-

tance is within acceptable 2V

ARM limits, the new

6.11.2 Aspen Return Monitor (A.R.M.)

The A.R.M. circuit converts the electrical resis

-

tance appearing in the return electrode circuit

into a digital value which can be processed by the

microprocessor. Software processes use this value

in conjunction with the SINGLE PAD/DUAL

PAD and MONITOR SET/ buttons to determine

when a RETURN FAULT condition exists. The

ASSIST resistance indicator is also driven by soft

-

ware to indicate the value of the measured DUAL

FOIL resistance in the 10 to 150 ohm range.

Figure 6.4 shows the approximate resistance vs.

number of illuminated bars in the resistance indi

-

cator. If no bars are lit, then the resistance is less

than approximately 10 ohms, and if 10 bars are

lit, the resistance is greater than approximately

150 ohms. It is not possible for just 1 or 9 bars

to be lit, unless a segment has failed.

The Handsense/A.R.M. schematic (Figure C-20)

contains the A.R.M. circuitry. It is comprised of

an oscillator section and an isolation section. The

isolation section employs a toroidal transformer,

T4, to couple the return electrode impedance to

the A.R.M. oscillator while isolating that circuit

from the effects of applied RF electrosurgical cur

-

rent and voltage. C27 and C30 split the return

current evenly between the two legs, thus mini

-

Loading...

Loading...