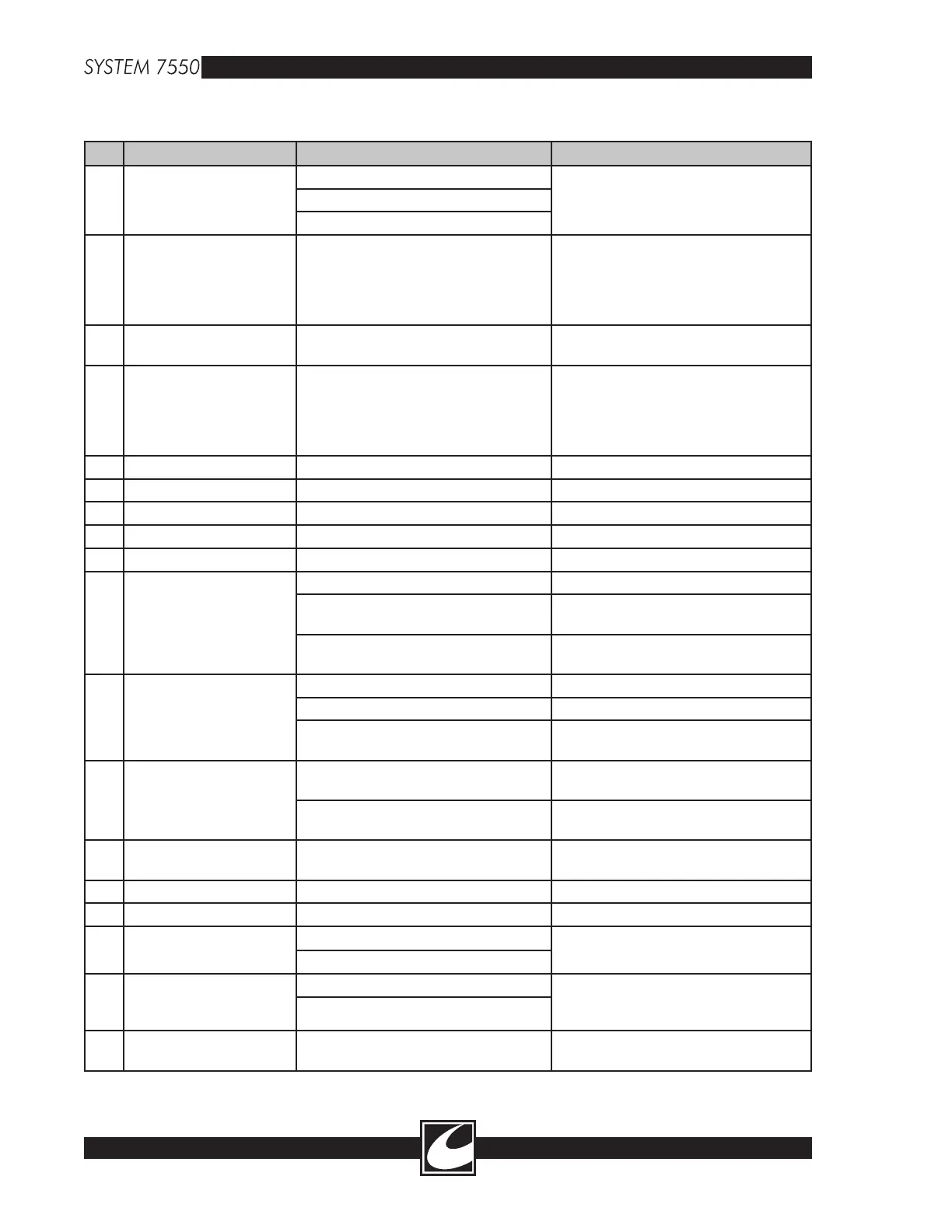

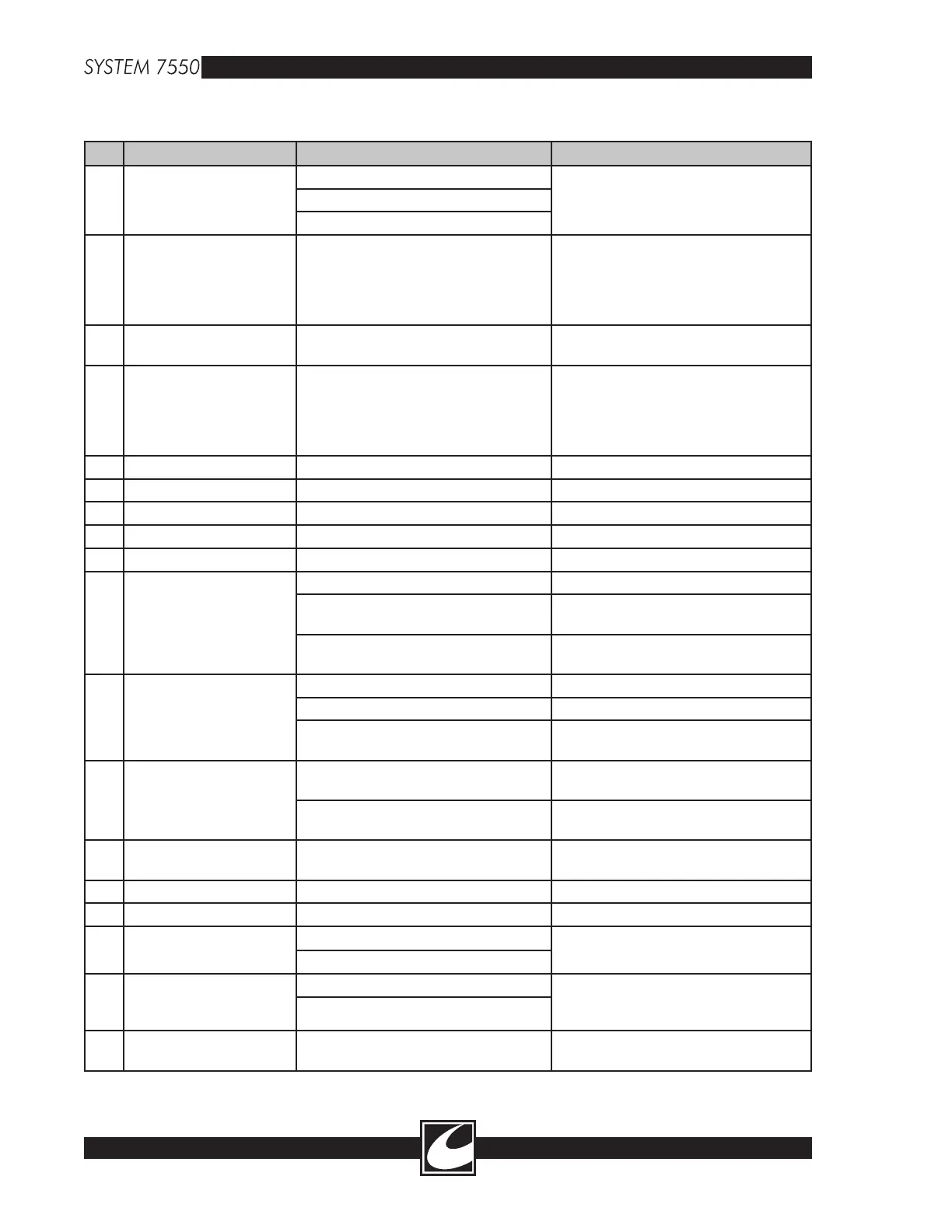

B-2

Control Microcontroller Failure Codes and Troubleshooting Tips

Err Reason Probable Problems Suggested Solutions

1 Stuck Front Panel Switch User pressing switch during power up. Disconnect J1 on the Display Panel and

power up again. If Err 1 is displayed,

then U5 on (A5) may be defective.

Front Panel overlay failed.

U5 (A5) failed.

2 Stuck Hand or Foot

Activation Request

• User pressing switch during power

up.

• Failed Handcontrol or Footcontrol.

• Failed component (A5 or A11)

• Disconnect accessories one at a time to

identify failed accessory - start with the

handcontrol if connected.

• Handcontrol signals - Active low.

• Footcontrol signals - Active high.

20 Illegal Default Switch

Setting

Default switch position 1 or 6 is ON. Position 1 and 6 should be OFF (see

maintenance section for TEST Mode).

26 Stuck encoder bits/Logic

device failed

Failed Logic Device (A5). • Identify which encoder causes the

error.

• Swap U16 & U33 for power encoder.

• Swap U31 & U32 for Blend or Flow

(look for a difference when swapping).

41 ARMCAL_10 Calibration Tolerance Error too low. Recalibrate - See Calibration Section.

42 ARMCAL_10 Calibration Tolerance Error too high. Recalibrate - See Calibration Section.

43 ARMCAL_150 Calibration Tolerance Error too low. Recalibrate - See Calibration Section.

44 armcal_150 Calibration Tolerance Error too high. Recalibrate - See Calibration Section.

55 Watchdog Reset Timing Error in U15 (A5).

111 FMON out of tolerance FMON out of calibration (A1). Recalibrate - See Calibration Section.

Flow Control Valve Driver shorted

(A1).

R58 (A1)should be 0 Volts in idle.

Argon tubes to X1 (A1) reversed. If A1 has been pulled from the card cage,

insure the tubes are connected correctly.

112 Flow Error FMON out of Calibration (A1). Recalibrate - See Calibration Section.

Handpiece occluded. Test at other flow rates.

Flow control circuit has failed. Flow too high for accessory (test in

Manual Mode or lower flow rate.

120 Controller and Monitor

do not agree on power

level.

Bad data transfer (A5). If only occurs once, then may be a tim

-

ing error.

PIA with encoder logic failed (A5). U16 or U33 may be bad - swap and

check for a different effect/code (A5).

200 Interrupt Unused Interrupt tripped. Reset System - Note Error code if it

reoccurs.

201 Mailbox Monitor did not read message (A5). If persistent, U19 may have failed (A5).

202 Mailbox Monitor did not respond (A5). If persistent, U19 may have failed (A5)

203 Mailbox error Bad data transfer (A5). Reset system - try again.

Mailbox failed (A5).

210 Bad Cal Data Calibration Data bad (A5). Recalibrate - see Calibration Section

(only the section for ABC at 11 & 149;

spray at 49, and A.R.M. open circuit).

EEPROM failed (A5).

216 RAM Failure External RAM has failed (U2)(A5). Reset System - Note error code if it reoc-

curs.

Loading...

Loading...