Service Handbook OGS/OGB

Step 8: Adjust MIN Speed

Instructions:

To adjust the burner for partial load you have to be in the Service programme

in Service point c27/c38 ="Nmax" (!) the value of the MIN speed setting (only

used while measuring the gas exhaust values at partial load!).

Instructions for adjusting the Service point are similar to those in Step 6.

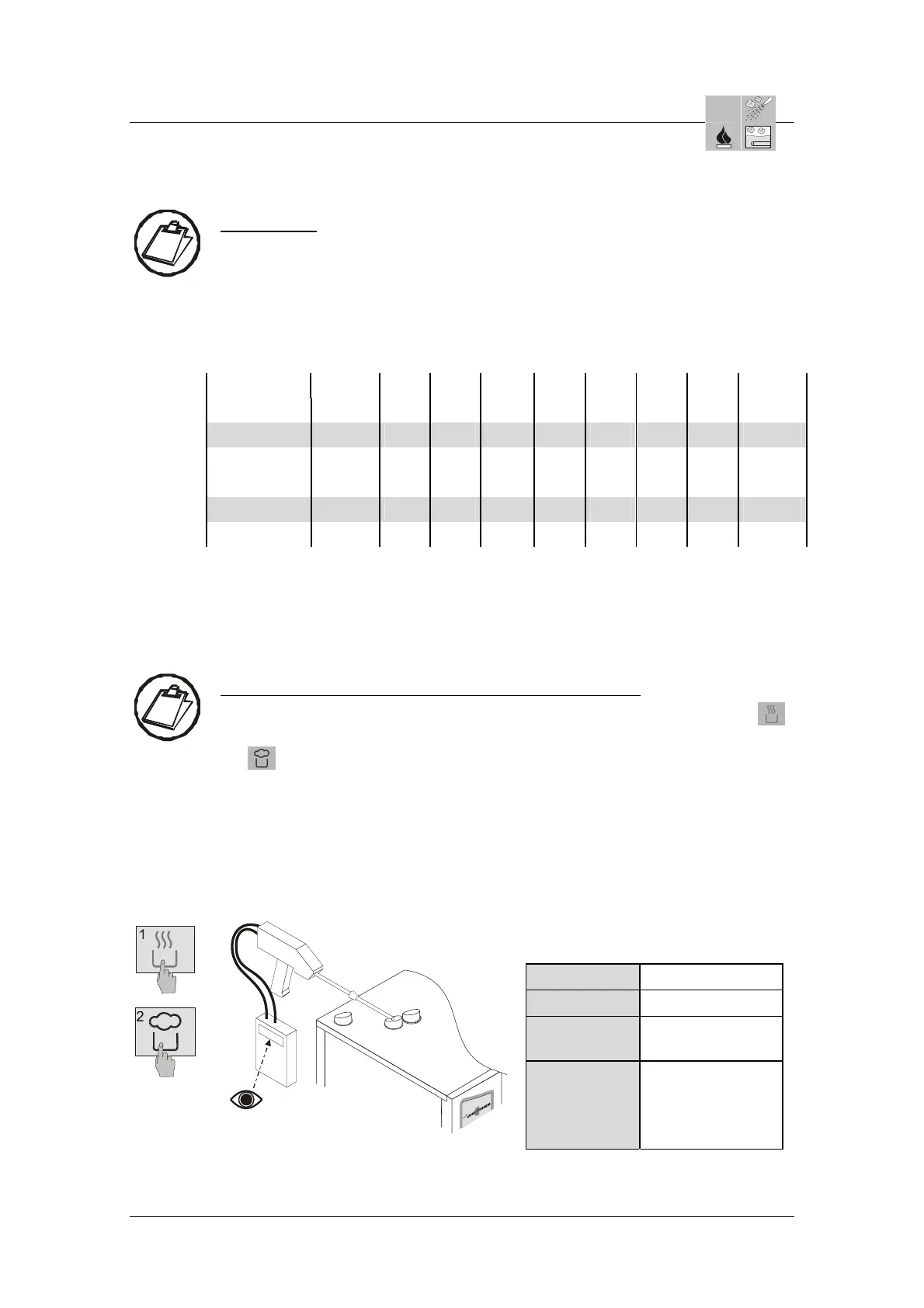

Chart 3: Speed (Start speed = Start)

6.10 6.20 10.10 10.20 12.20 20.10 20.20

HL MIN c26

4800 2800 2800 2800 2800 2800 2800

HL MAX c27

4800 2800 2800 2800 2800 2800 2800

HL START c28

4800 4200 4200 4500 4500 4200 4500

DE MIN c37

4500 4700 3000 3200 3200 3200 3200

DE MAX c38

4500 2800* 3000 3200 3200 3200 3200

DE START c39

4500 2800 3000 3200 3200 3200 3200

* Exception for 6.20 (adjust the Start speed, not the Min speed value)

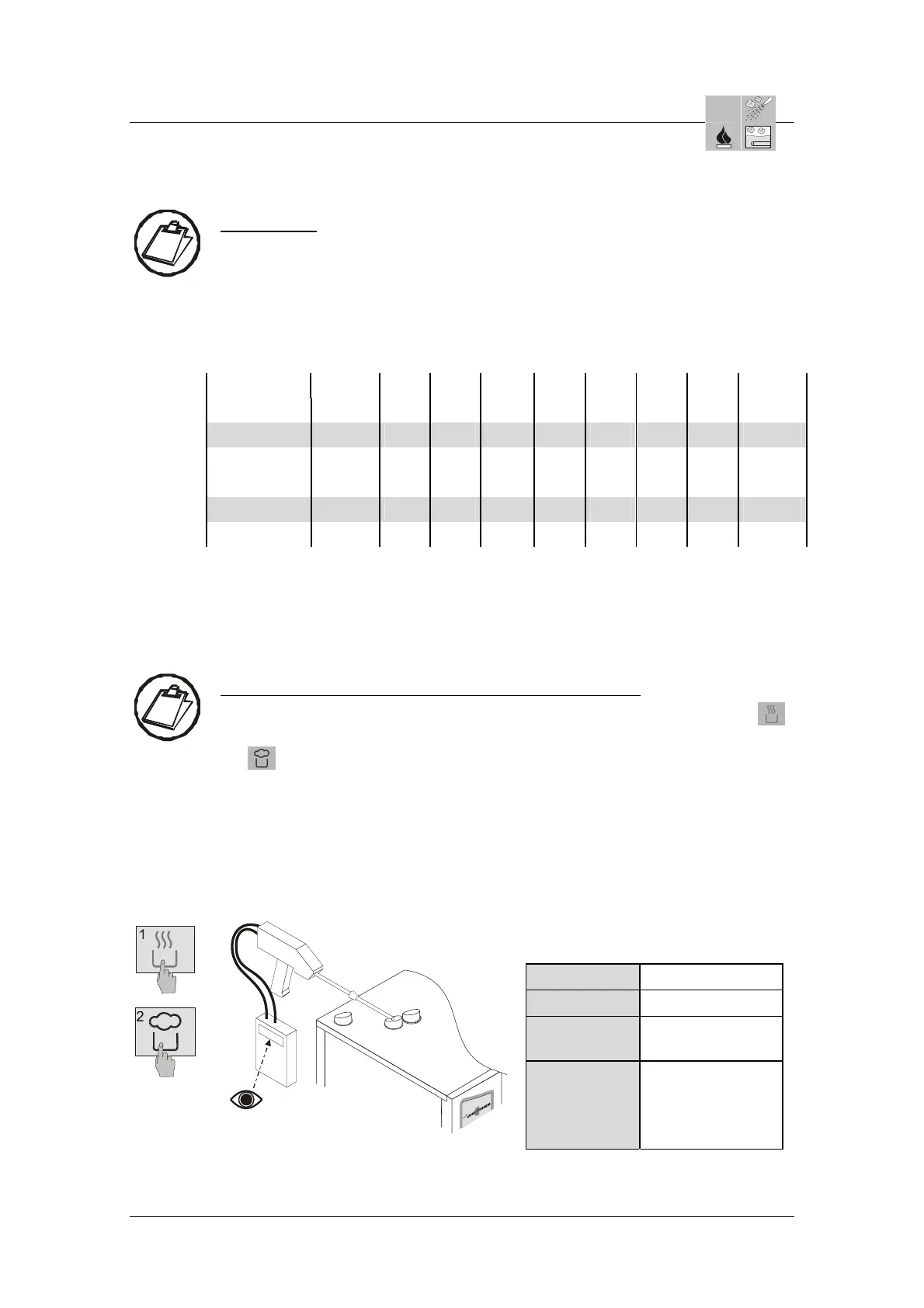

Step 9: Start burner and measure the gas exhaust values at

MIN speed

Instructions: Start unit and measure gas exhaust values

When adjusting the convection burners Start the Convection programme ;

When adjusting the steam generator burners Start the Steam programme

.

The burner blower runs at the Start speed. After successful ignition of the

burner, it is automatically decreased to MIN speed.

Measure the gas exhaust values, after 1 minute read the measured value and

check with the CO

2

value on Chart 5 "Gas exhaust value @ Min “.

Record the CO

2

and CO values. At a CO value > 500 ppm switch off the unit

and check the cause of the excessive CO value.

Page 8 / 12

Chart 5: Gas exhaust value @ Min

All gas types

O

2

.= 5,5%±0,3%

All gas types

= 1,35±0,02

Erdgas /

Natural Gas

CO

2

= 8,8%±0,1%

LP Gas =

Propan

Butan

CO

2

=

10,3%±0,2%

CO

2

=

11,6%±0,3%

AS/11-2011 / Part No.: 7016396 6_25e_Readjusting the Gas valves_d

Loading...

Loading...