Form 6 Recloser Control Testing

Instructions

These instructions describe the testing of the Form 6

recloser control.

Communication Ports

Verify that the communication settings have been appropri-

ately configured for your selected communication protocol.

For information on configuring communications refer to

the appropriate instructions:

• S280-70-4 Form 6 Control Programming Guide

• S280-70-9 Form 6 Triple-Single Control

Programming Guide

Contact Input/Outputs

Standard Default Supervisory Input

Control and Output Status Contacts

Test inputs/outputs by asserting appropriate alarms per

the ProView™ software to verify that all contact outputs

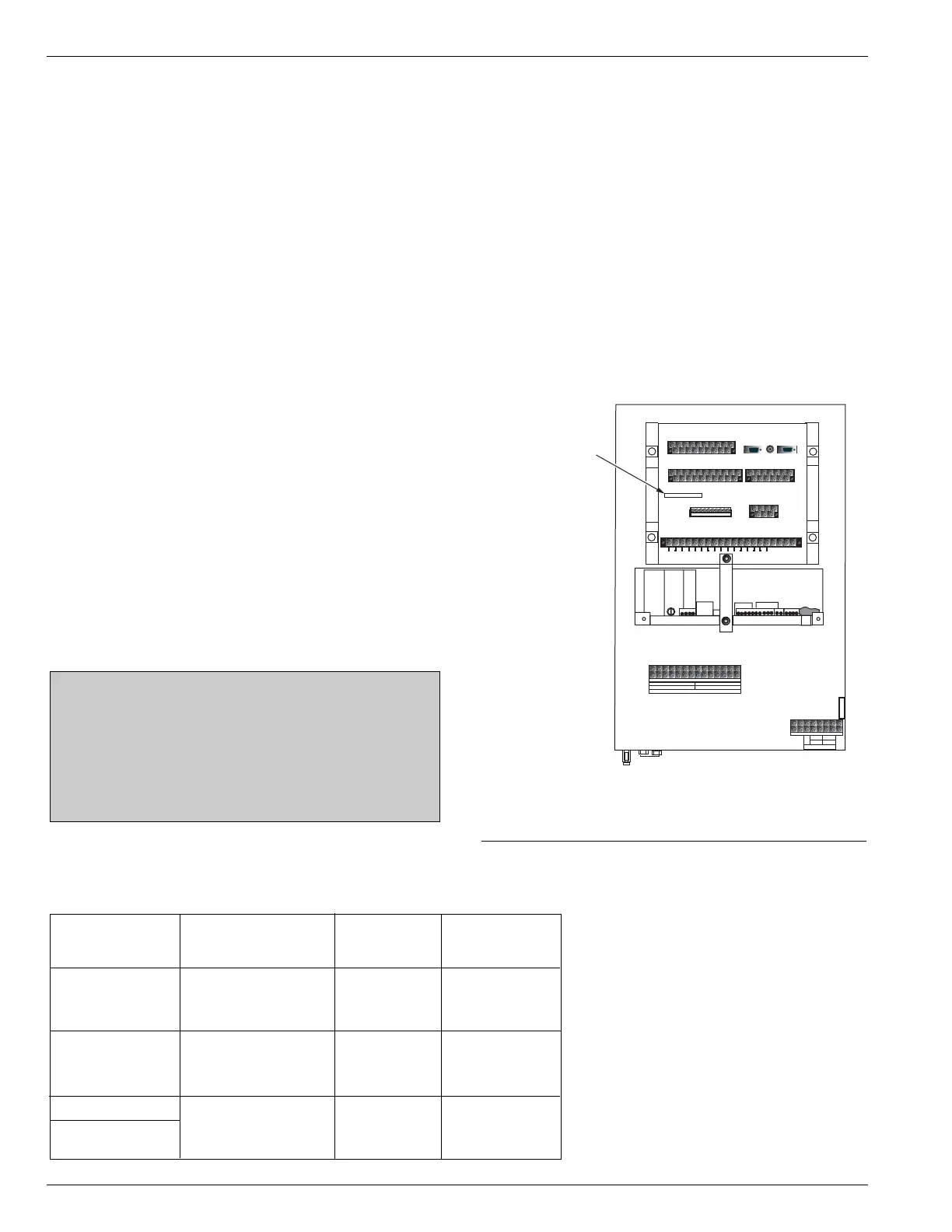

operate (open and close). Figures 8 and 9 show the loca-

tion of the controls module manufacturing numbers.

Refer to Tables 2 and 3 for Operating Voltage

Requirements for Standard and Optional Supervisory

Inputs.

For information on testing refer to the appropriate

instructions:

• Service Information S280-70-1 Form 6 Rack Mount

Control Installation and Operation Instructions

• Service Information S280-70-2 Form 6 Yard Mount

Control Installation and Operation Instructions

• Service Information S280-70-3 Form 6 Pole Mount

Control Installation and Operation Instructions

• Service Information S280-70-7 Form 6 Triple-Single

Pole Mount Control Installation and Operation

Instructions

Form 6 Recloser Control Disassembly, Reassembly, and Testing Instructions

10

TESTING

CAUTION: Equipment damage; misoperation.

External leads must be shielded and the shield must be

grounded at both ends. Terminate each lead with a 320

Vac, 160 Joules metal oxide resistor (MOV), or equiva-

lent, at the remote end. Attach MOVs between the

leads and ground. Failure to properly shield and protect

leads can result in equipment damage and/or uninten-

tional operation. G117.3

Figure 8.

Module Mfg. No. location on back of Form 6 pole

mount control.

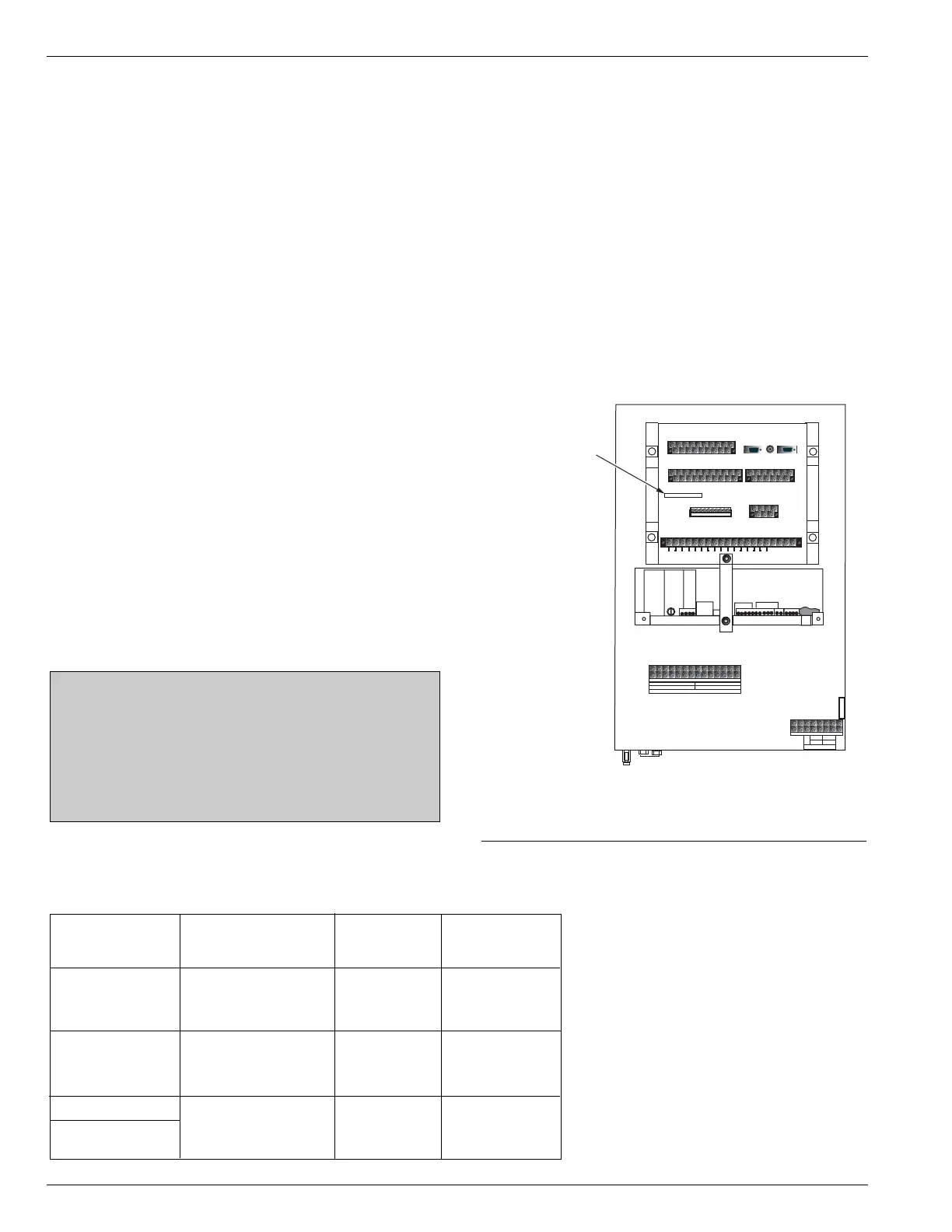

Mfg. No. 6A0016010XX

Module Mfg. No.

Minimum

Module Nominal Operating

Mfg. No.* Input Voltage Current Time

6A00160101 12 Vdc – 48 Vdc 5 mA 5 milliseconds

through

6A00160104

6A00160105 48 Vdc – 125 Vdc, 5 mA 5 milliseconds

through 120 Vac

6A00160108

6A00160161 12 Vdc – 250 Vdc, 5 mA 5 milliseconds

6A00160160 120 Vac-240 Vac

(Triple-Single)

TABLE 2

Operating Voltage Requirements for Standard and Optional

Supervisory Inputs for Form 6 Pole Mount Recloser Control

Refer to Figure 6 for location of Module Mfg. No.

Loading...

Loading...