Form 6 Recloser Control

Disassembly Instructions

These instructions describe the disassembly of the Form

6 recloser control.

1. Remove the Form 6 Control from Service. Refer to

appropriate Service Information Instructions:

• Service Information S280-70-1 Form 6 Rack Mount

Control Installation and Operation Instructions

Remove the Control from Service section

• Service Information S280-70-2 Form 6 Yard Mount

Control Installation and Operation Instructions

Remove the Control from Service section

• Service Information S280-70-3 Form 6 Pole Mount

Control Installation and Operation Instructions

Remove the Control from Service section

• Service Information S280-70-7 Form 6 Triple

Single Pole Mount Control Installation and

Operation Instructions Remove the Control from

Service section

2. Carefully transport the recloser control to a suitable

service facility.

Note: The entire disassembly, reassembly, and testing

process should be conducted in a clean environ-

ment, such as a repair shop.

This step applies to Form 6 Pole and Yard mount controls.

3. Remove module from cabinet as applicable.

A. For complete scheme structure and verification

refer to appropriate instructions:

• Service Information S280-70-4 Form 6 Control

Schemes section

• Service Information S280-70-9 Form 6-TS

Control Schemes section

B. Disconnect SCADA communications to the Form 6

control.

C. Remove all applicable connecting wires from

module.

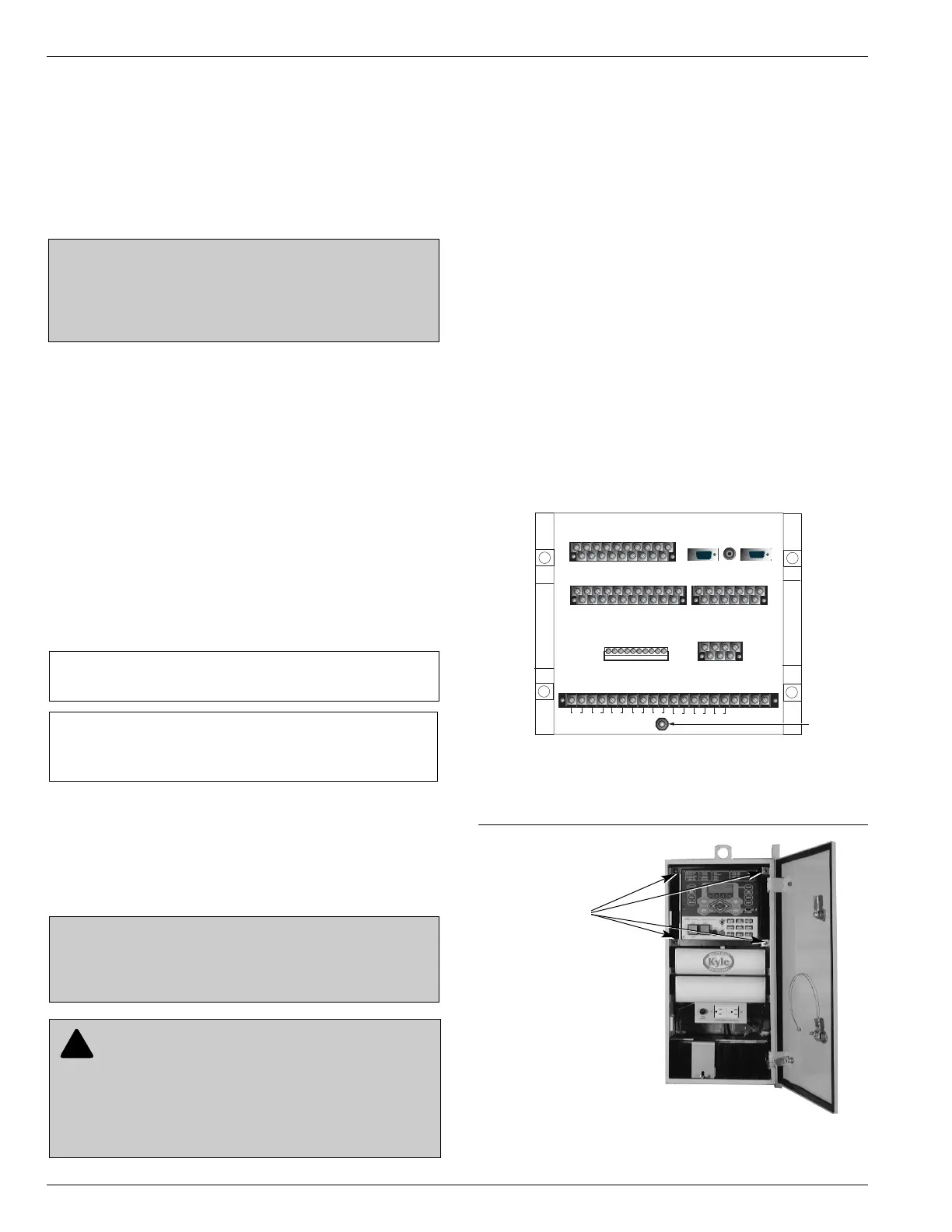

D. Remove the 7/16 inch grounding nut and lock-

washers located on the bottom of the control mod-

ule (Figure 2).

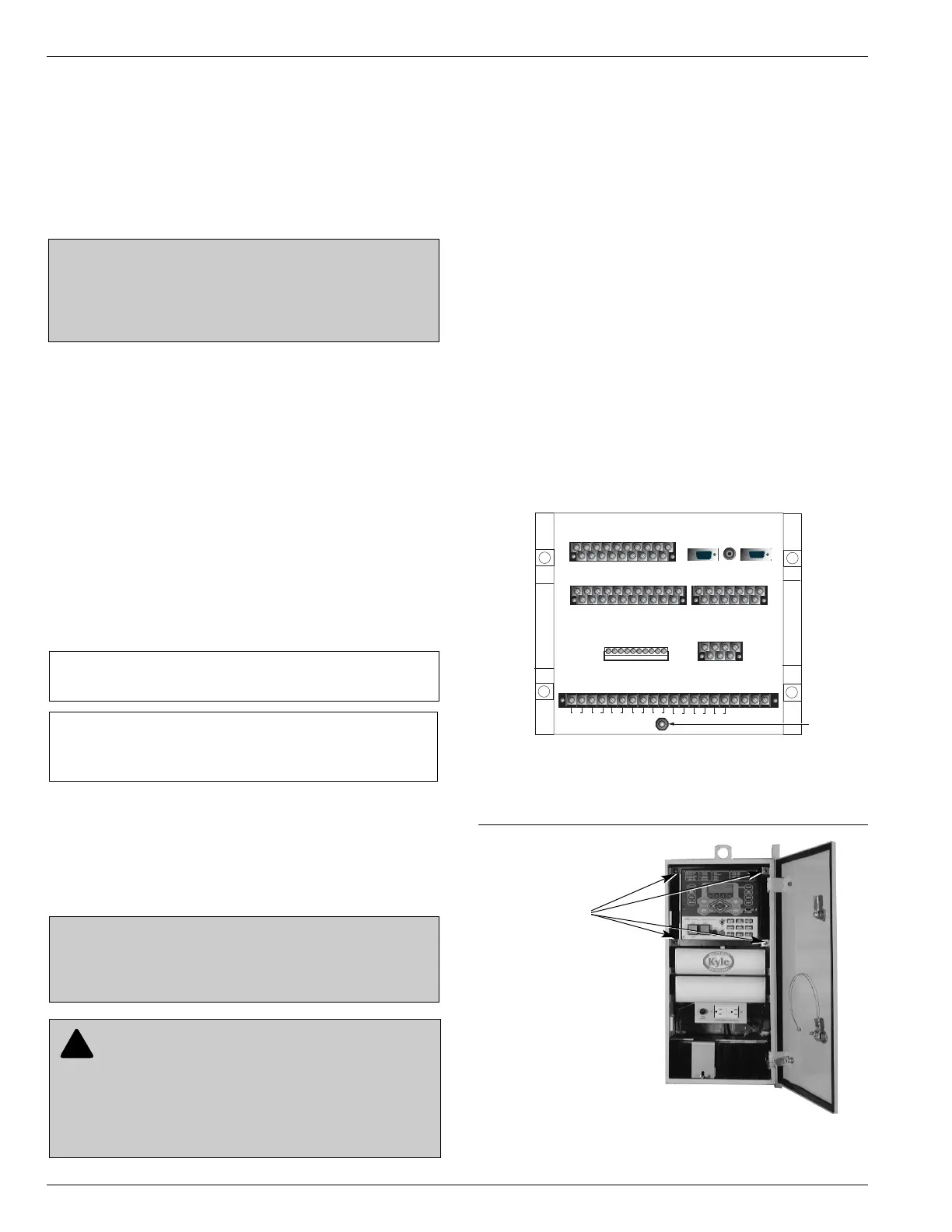

E. Remove the four mounting nuts that secure the

front of the module to the cabinet (Figure 3).

Form 6 Recloser Control Disassembly, Reassembly, and Testing Instructions

4

DISASSEMBLY

CAUTION: Recloser misoperation. The control must

be removed from service prior to performing any main-

tenance, testing, or programming changes. Failure to

comply can result in misoperation (unintentional oper-

ation) of the recloser. T216.2

IMPORTANT: Isolate all power connections to the

Form 6 recloser control, i.e., AC voltage sensing and

SCADA, before removing control from service.

IMPORTANT: Make sure the power is turned off and

the battery is disconnected.

CAUTION: Equipment damage. Always wear a

grounding wrist strap to control static electricity before

handling circuit boards. Failure to use this strap may

result in circuit board damage.

T253.1

Figure 2.

Location of grounding nut and lockwashers on the

rear panel of the Form 6 pole mount control (below

SN 10000).

CAUTION: Recloser misoperation. Before

downloading configuration files or settings to the

equipment, verify that the files and settings are correct

for the location and application. Downloading configu-

ration files or settings designed for a different location

or application can result in severe personal injury and

equipment damage. G133.0

Loading...

Loading...