i i illll, ii,i ii ,ll .... , ....................................

i/ J iui

MBLY

TO INSTALL THE UPPER HANDLE AND

CRANK ASSEMBLY

• Removethe screws,flatwashers,to.washers and

hexnutssecudngthe shifterplateinthe lowerholes

ofthelowerhandle..

• Loosen,t_Jtdonotremove,thescrews,flatwashers,

lockwashers, and hex nutsinthe upperholesof the

lowerhandle_

• Raiseupperhandle into operatingposition.,Upper

handleshouldbeto theoutsideof the lower handle

and shifterplate to the inside.

• Replacethe screws0flatwashers,lockwashers, and

hexnutsthroughthehandlesandshifterplate.Donot

lightenuntilallboltsare in ptace_T'_jhtenlefthand

sidefirst.

NOTE: Unless you have the assistanceof anotherper-

son,itmay beeasiertoinstallonesideofthehandleatthe

time.

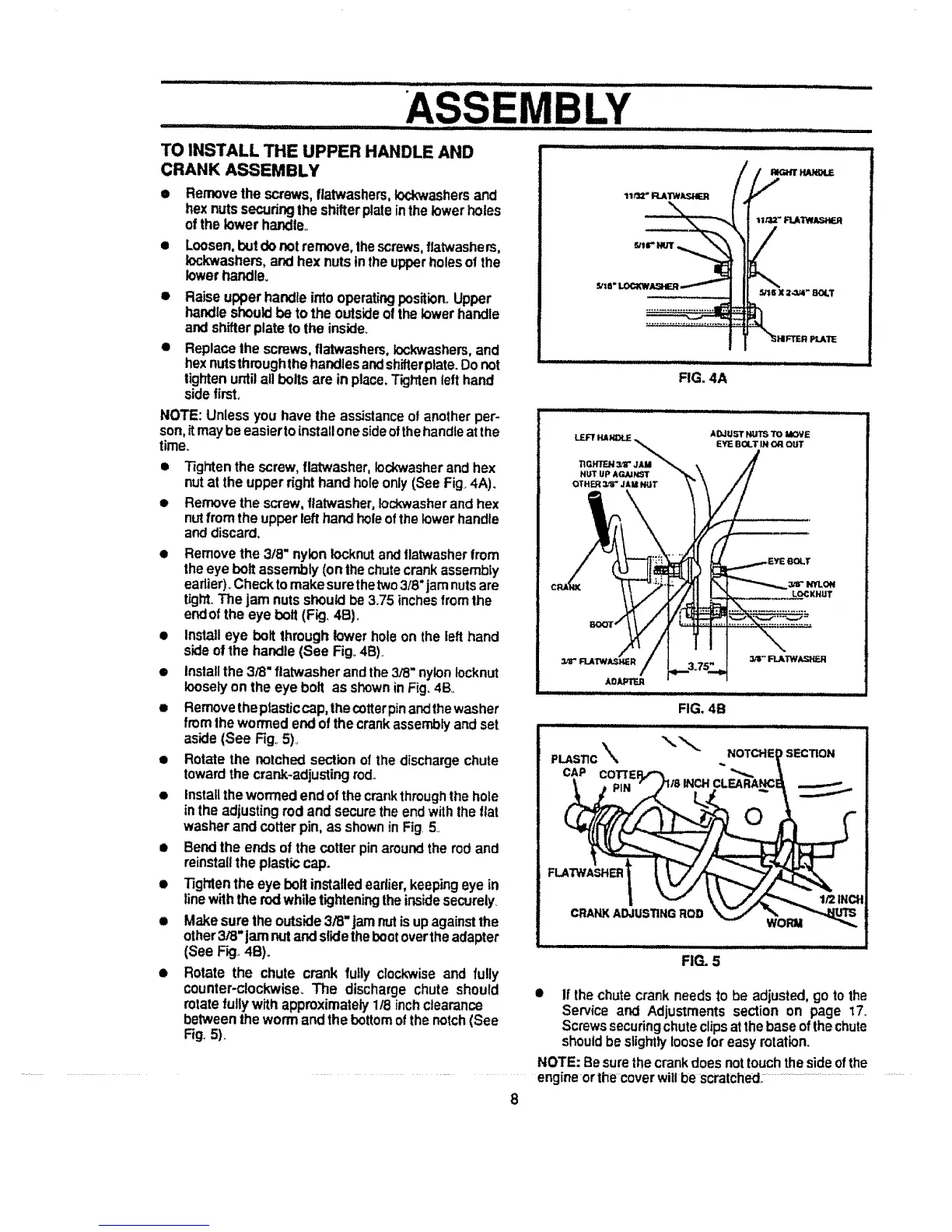

• Tightenthe screw,flat'washer,Iockwasherand hex

nutat the upperdght hand holeonly (See Fig,4A),

• Removethe screw,flatwasher,Iockwasherandhex

nutfrom the upperlefthand holeofthe lowerhandle

and discard,

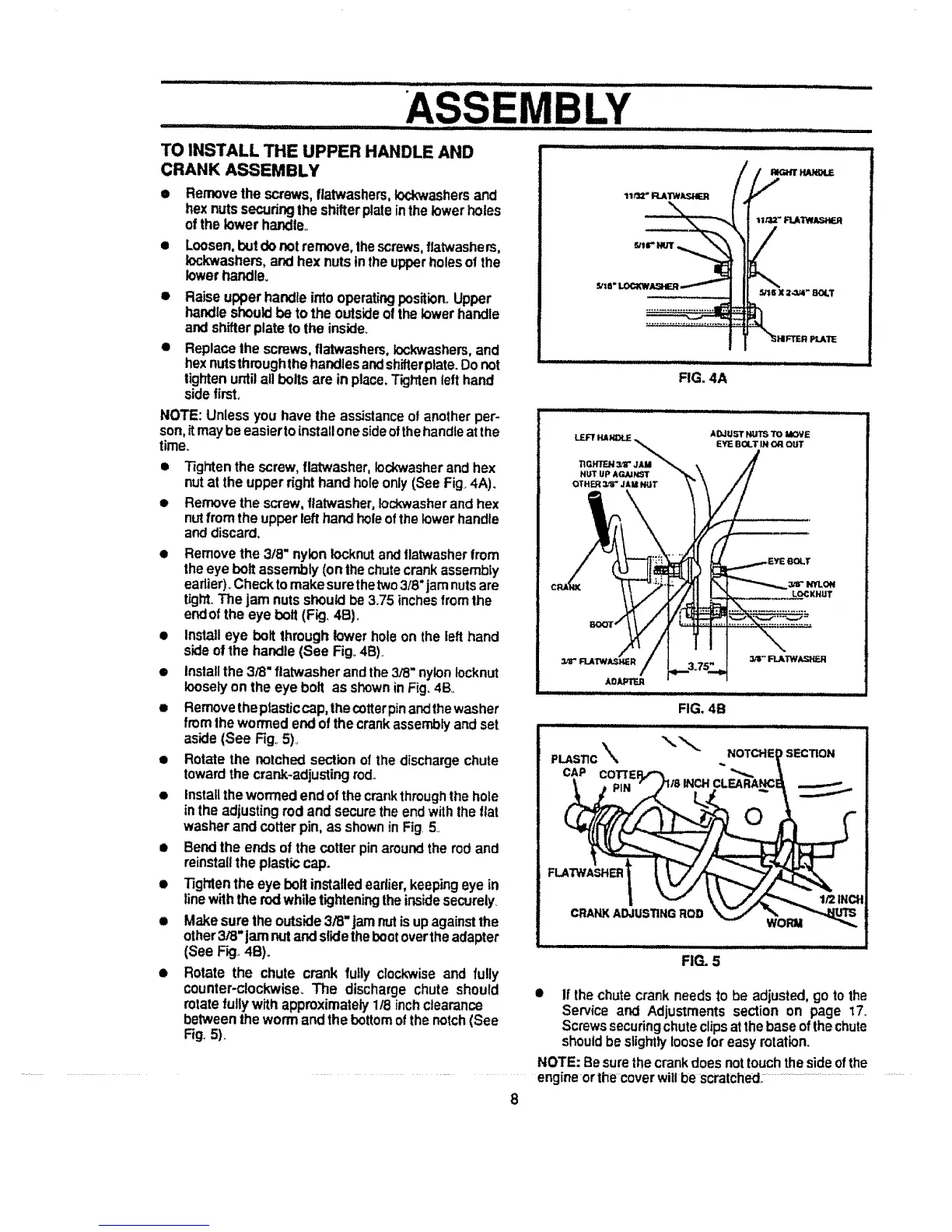

• Removethe 3/8" nyloniocknutand flatwasherfrom

theeye bolt assembly(onlhe chutecrankassembly

eadier)_Checktomakesurethetwo3/8"jamnutsare

tight.The jam nutsshouldbe3.75 inches fromthe

endofthe eye bolt (Fig. 4B).

• Installeye bolt throughlower hole on the left hand

sideof the handle(See Fig.,4B)_

• Installthe 3/8"ftatwasherandthe3/8"nylonlocknut

looselyon the eye bolt as showninFig_4Bo

• Removetheptasticcap,thecotterpinandthewasher

from the wormedend ofthe crankassemblyandset

aside (See Fig°5)_

• Rotate the notchedsectionof the dischargechute

towardthe crank*adjustingrod..

• Installthewormed endof thecrankthroughthehole

in the adjustingrod and securethe endwiththe flat

washer andcotterpin, as shownin Fig.5

• Bendthe ends of the cotter pin aroundthe rodand

reinstallthe plasticcap.

• Tighten the eye bolt installedearlier, keepingeye in

linewiththe rodwhiletighteningtheinsidesecurely

• Make surethe outside3/8"jam nutisupagainstthe

other3/8"jamnutandslidethebootovertheadapter

(See F_,.4B).

• Rotate the chute crank fully clockwiseand fully

counter-clockwise, The discharge chute should

rotatefullywith approximately 1/8 inchclearance

betweenthewormand the bottomofthenotch(See

Fig.5).

_'tB"

FIG. 4A

= _

FIG. 5

• If thechutecrankneedsto be adjusted, go to the

Service and Adjustments section on page 17_

Screwssecuringchuteclipsatthebaseofthechute

shouldbe slightlyloose for easyrotation.

NOTE: Besurethe crankdoes nottouchthe sideofthe

................................................. engineorthe coverwillbe scratched,:......................................................................

8

Loading...

Loading...