SERVICE AND ADJUSTMENTS

CAUTION: ALWAYS DISCONNECTTHE

SPARK PLUG WIRE AND TIE BACK

AWAY FROMTHE PLUG BEFORE MAK-

ING ANY ADJUSTMENTS OR REPAIRS.

TO ADJUST SKID HEIGHT

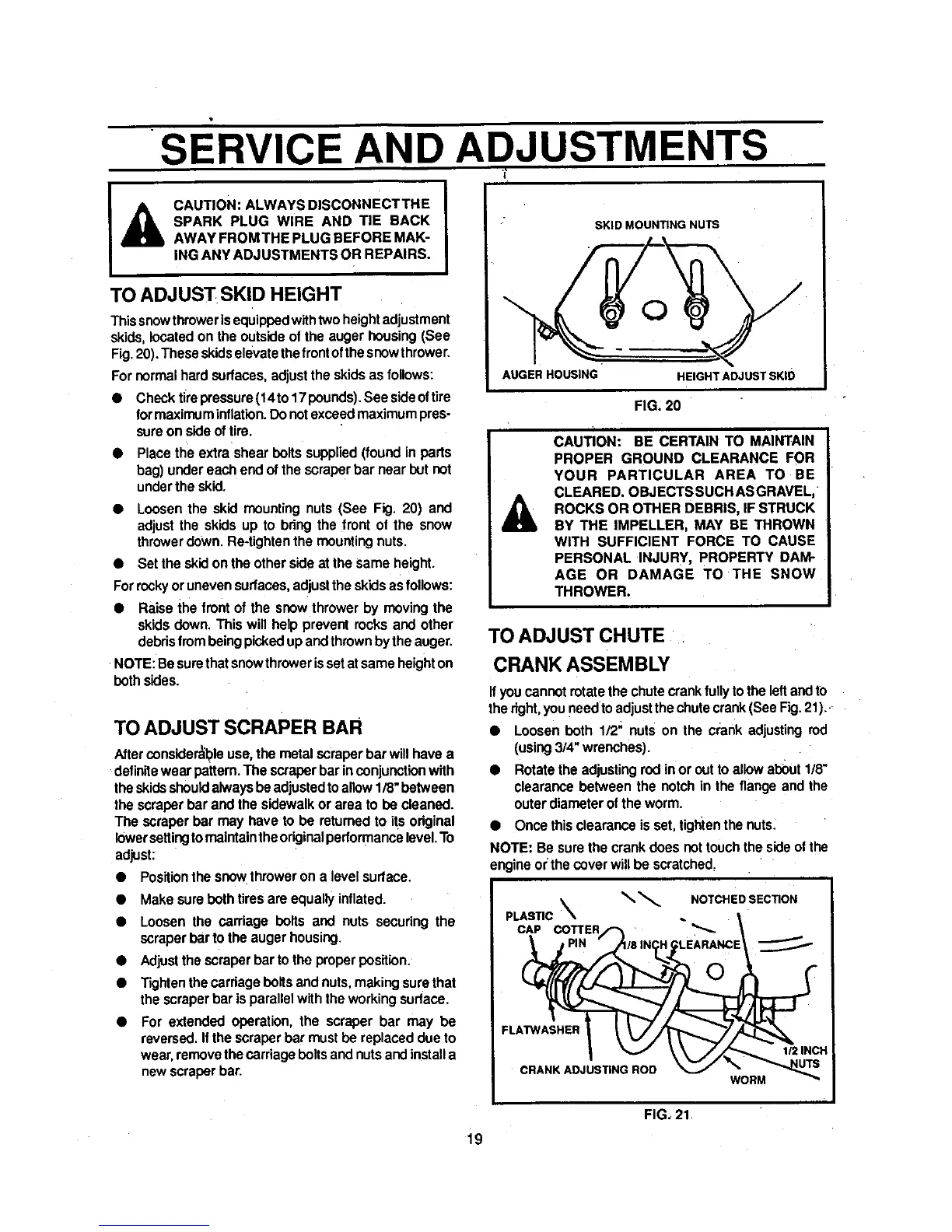

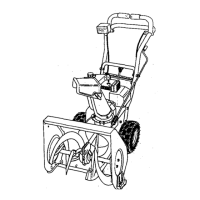

Thissnowthrowerisequippedwithtwo heightadjustment

skids,locatedon the outsideof the auger housing(See

Fig.20).These skidselevatethefront ofthesnowthrower.

For normalhardsudaces, adjustthe skids as follows:

• Check tirepressure(14to 17 pounds).See sideoftire

formaximuminflation.Donotexceed maximumpres-

sureon sideoftire.

• Place the extra shear boltssupplied(found in parts

bag) under eachend of thescraperbar near but not

underthe skid.

• Loosen the skid mountingnuts (See Fig. 20) and

adjustthe skids up to bring the front of the snow

throwerdown. Re-tightenthe mounting nuts.

• Set the skid on the othersideat the same height.

Forrockyoruneven surfaces,adjustthe skidsas follows:

• Raise the frontof the snowthrower by movingthe

skids down. This will help prevent rocks and other

debrisfrombeingpickedup andthrownbythe auger.

NOTE: Be surethatsnowthrowerissetat sameheighton

both sides.

TOADJUSTSCRAPER BAR

Afterconsiderableuse,the metalscraper bar willhave a

definitewear pattern. The scraperbar inconjunctionwith

theskidsshouldalwaysbeadjustedtoallow1/8"between

the scraperbar and the sidewalkor area to be cleaned.

The scraper bar may have to be returned to its original

lowersettingtomaintaintheoriginalperformancelevel.To

adjust:

• Positionthe snowthroweron a level sudace.

• Make sureboth tiresare equallyinflated.

• Loosen the carriage bolts and nuts securing the

scraperbar to the auger housing.

• Adjustthe scraper bar to the properposition.

• Tightenthecarriagebolts and nuts,making surethat

the scraperbar is parallelwiththe workingsurface.

For extended operation, the scraper bar may be

reversed. Ifthe scraper bar mustbe replaceddue to

wear,removethecarriage bolts andnutsandinstalla

newscraperbar.

SKID MOUNTING NUTS

AUGER HOUSING

HEIGHTADJUSTSKID

FIG. 20

A

CAUTION: BE CERTAIN TO MAINTAIN

PROPER GROUND CLEARANCE FOR

YOUR PARTICULAR AREA TO BE

CLEARED. OBJECTSSUCH ASGRAVEL,

ROCKS OR OTHER DEBRIS, IF STRUCK

BY THE IMPELLER, MAY BE THROWN

WITH SUFFICIENT FORCE TO CAUSE

PERSONAL INJURY, PROPERTY DAM-

AGE OR DAMAGE TO THE SNOW

THROWER.

TO ADJUST CHUTE

CRANK ASSEMBLY

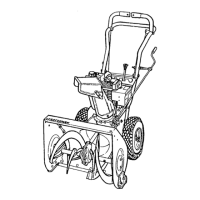

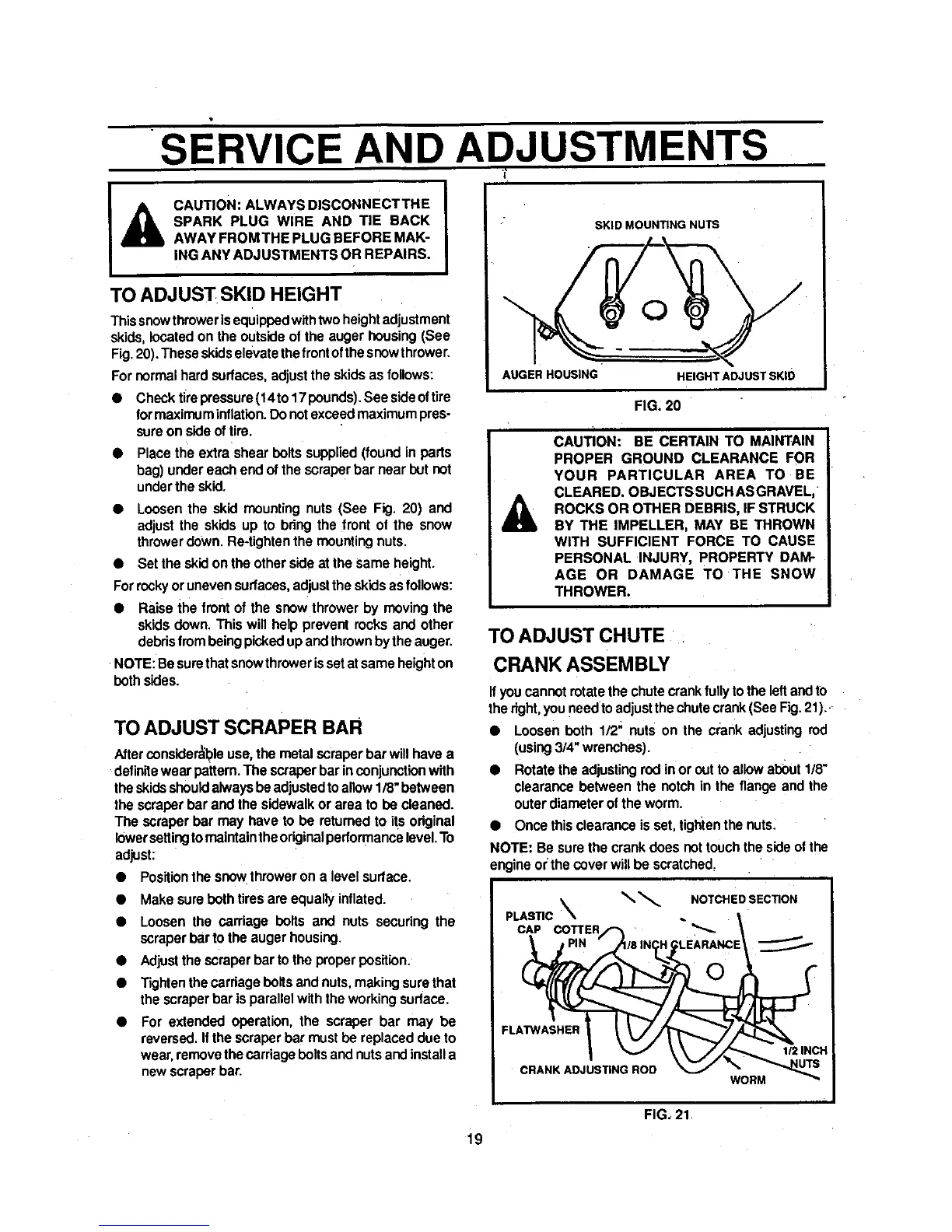

Ifyou cannot rotatethe chutecrankfully tothe leftandto

thedght,youneedto adjustthe chutecrank(See Fig.21).

• Loosen both 1/2" nuts on the crank adjustingrod

(using3/4" wrenches).

• Rotatethe adjustingrodin or outto allowabout 1/8"

clearancebetween the notch in the flange and the

outerdiameterofthe worm.

• Once thisclearance isset, tigtltenthe nuts.

NOTE: Be surethe crank does not touchthe sideofthe

engineor the coverwill be scratched.

_ NOTCHED SECTION

PLASTIC

CAP COTTER "_-

FLATWASHER

CRANK ADJUSTING ROD

WORM

1/2 INCH

FIG, 21

i9

Loading...

Loading...