ENGLISH

6

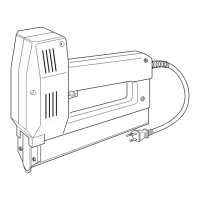

Proper Hand Position (Fig.D)

WARNING: To reduce the risk of serious personal injury,

ALWAYS use proper hand position asshown.

WARNING: To reduce the risk of serious personal

injury, ALWAYS hold securely in anticipation of a

suddenreaction.

Proper hand position requires one hand on the main

handle

9

.

OPERATION

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove air supply before

making any adjustments or removing/installing

attachments or accessories. An accidental actuation

can causeinjury.

Using the Secondary Trigger (Fig.A)

WARNING: To reduce the risk of injury, Always wear

proper eye [ANSI Z87.1 (CAN/CSA Z94.3)] and hearing

protection [ANSI S12.6 (S3.19)] when operating

thistool.

WARNING: Do not keep trigger depressed when tool is

not in use. Serious personal injury mayresult.

WARNING: Disconnect air line from tool and remove

fasteners from magazine before making adjustments.

Serious personal injury mayresult.

The tool is locked off until the secondary trigger

2

isdepressed.

• Before you use the tool, be sure that the compressor

tanks have been properlydrained. NOTE: Use a filter and

regulator whenpossible.

• Wear proper eye, hearing and respiratoryprotection.

• Remove all fasteners from the magazine.

• Check for smooth and proper operation of contact trip

and pusher assemblies. Do not use tool if either assembly

is not functioning properly. NEVER use a tool that has the

contact trip restrained in the upposition.

• Check air supply: Ensure air pressure does not exceed

operating limits; 60to 100p.s.i.g., (4.1 to 6.9 kg/cm

2

).

• Lubricate tool:

‑ Use CRAFTSMAN pneumatic tool oil or a

non-detergent S.A.E. 20weight oil. DO NOT use

detergent oil or additives as they will damage O-rings

and rubberparts.

‑ Use a filter whenpossible.

‑ Add 5to 7drops of oil in the air fitting a least twice

aday.

• Keep tool pointed away from yourself andothers.

• Connect airhose.

• Check for audible leaks around valves and gaskets. Never

use a tool that leaks or has damagedparts.

Preparing the Tool

WARNING: Read the section titled IMPORTANT

SAFETY INSTRUCTIONS at the beginning of this

manual. Always wear proper eye [ANSI Z87.1 (CAN/

CSA Z94.3)] and hearing protection [ANSI S12.6 (S3.19)]

when operating this tool. Keep the fastener pointed

away from yourself and others. For safe operation,

complete the following procedures and checks before

each use of thefastener.

NOTICE: To reduce the risk of damage to the tool,

only use pneumatic tool oil or a non‑detergent SAE

20weight oil. Oil with additives or detergent will

damage toolparts.

Trigger (Fig.A)

WARNING: Keep fingers AWAY from trigger when not

driving fasteners to avoid accidental firing. Never carry

tool with finger ontrigger.

WARNING: Once the secondary trigger is pulled the

tool will drive a fastenere every time the primary trigger

ispulled.

This tool is equipped with with a dual trigger actuation

system. the secondary trigger

2

must be depressed in order

to depress the primary trigger

1

. Each time the primary

trigger is depressed the tool will fire afastener.

Air Fitting (Fig.B, C)

The tool is equipped with a 1/4” (6.4mm) male quick

connector coupling. A 3/8” (9.5mm) male quick connector

coupling may be used when a 1/4” (6.4mm) supply line is

not available.

NOTE: A 3/8” (9.5mm) supply line (and fittings) are required

for maximum tool performance. IMPORTANT: Always use

couplings that relieve all pressure from the tool when it

is disconnected from the power supply. Always use hose

connectors that shut off air supply from compressor when

the tool is disconnected.

To Install an Air Fitting

1. Wrap the male end of the fitting with thread seal tape

prior to assembly to eliminate airleaks.

2. To install a 1/4” (6.4mm) fitting: screw it directly into the

air inlet

3

and tighten firmly. NOTE: If a cap is in the air

inlet, remove it prior to inserting the fitting.

3. To install a 3/8” (9.5mm) fitting: screw the fitting into the

3/8” (9.5mm) adapter and then into the air inlet of the

tool and tightenfirmly.

FASTENER SPECIFICATIONS

Model

Nail 23 gauge pin nails

Lengths 1/2” (13 mm) –1” (25 mm)

Air Inlet 1/4” NPT (6.4 mm)

NOTE: Use only CRAFTSMAN approved fasteners.

Loading...

Loading...