POSITION DRIVE CONTROL LEVERS

The ddve control levers of the tractor are lowered for

shipping purposes. To accomplish this, the flange lock

nut, hex screw, and flat washer normally usedto secure

each control lever to its pivot bracket are removed. The

hardware is then installedin the slotted hole of each

control lever for shipment. The control levers must be

moved to their operating position. To reposition the con-

trol levers for operation, proceed as follows:

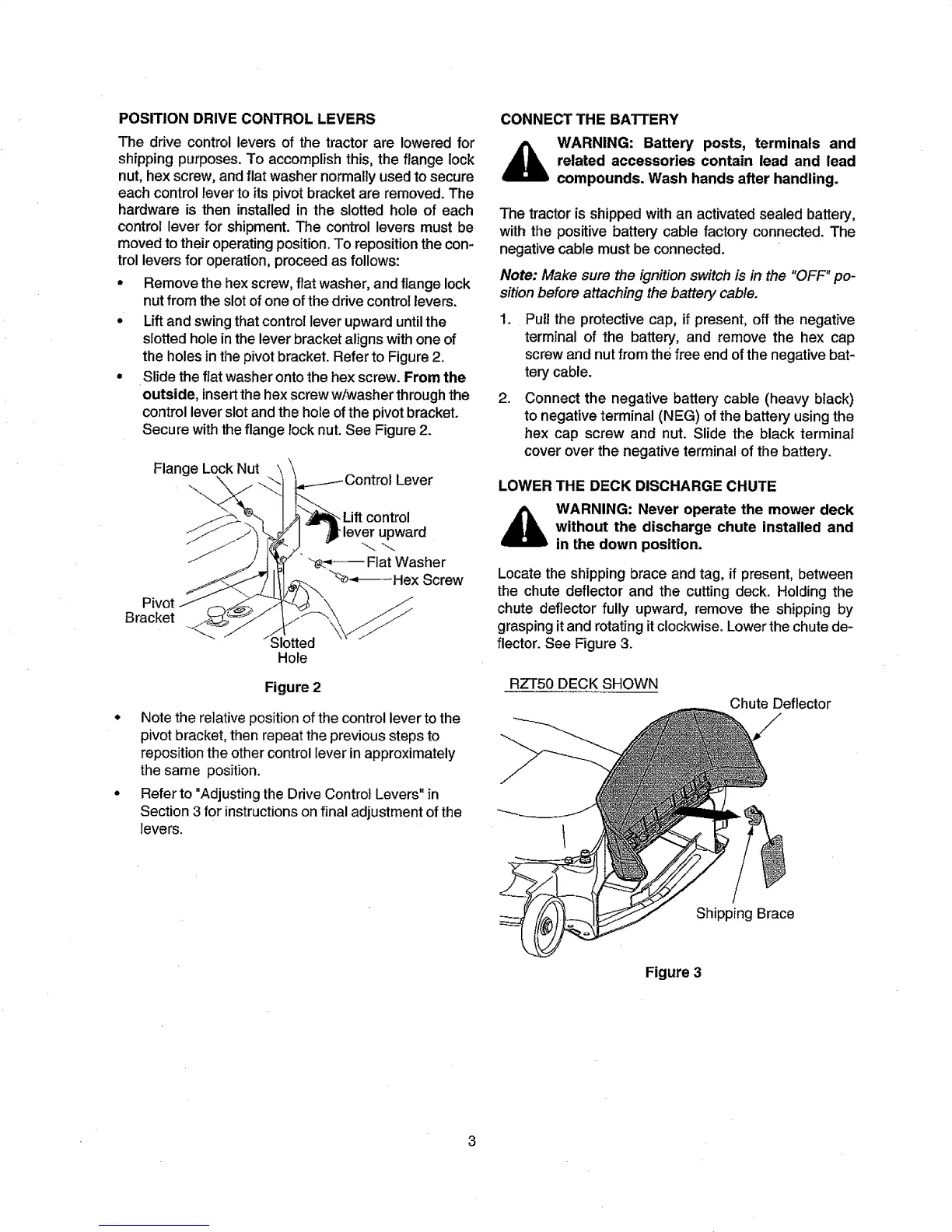

- Remove the hex screw, flat washer, and flange lock

nutfrom the slot of one of the drive control levers.

- Lift and swing that controt lever upward until the

slotted hole in the lever bracket aligns with one of

the holes in the pivot bracket. Refer to Figure 2.

• Slide the fiat washer onto the hex screw. From the

outside, insertthe hex screw w/washer through the

control lever slot and the hole of the pivot bracket.

Secure with the flange rock nut. See Figure 2.

Flange Lock Nut

\ Lever

.Liftcontrol

upward

Fiat Washer

"x_*_--Hex Screw

Bracket

Slotted

Hole

Figure 2

° Note the relative position of the control lever to the

pivot bracket, then repeat the previous steps to

reposition the other control fever in approximately

the same position.

° Refer to "Adjusting the Drive Control Levers" in

Section 3 for instructions on final adjustment of the

levers.

CONNECT THE BATTERY

WARNING: Battery posts, terminals and

related accessories contain lead and lead

compounds. Wash hands after handling.

The tractor is shipped with an activated sealed battery,

with the positive battery cable factory connected. The

negative cable must be connected.

Note: Make sure the ignition switch is in the "OFF" po-

sition before attaching the battery cable.

.

,

Pull the protective cap, if present, off the negative

terminal of the battery, and remove the hex cap

screw and nut from the free end of the negative bat-

terycable.

Connect the negative battery cable (heavy black)

to negative terminal (NEG) of the battery using the

hex cap screw and nut. Slide the black terminal

cover over the negative terminal of the battery.

LOWER THE DECK DISCHARGE CHUTE

WARNING: Never operate the mower deck

without the discharge chute installed and

in the down position,

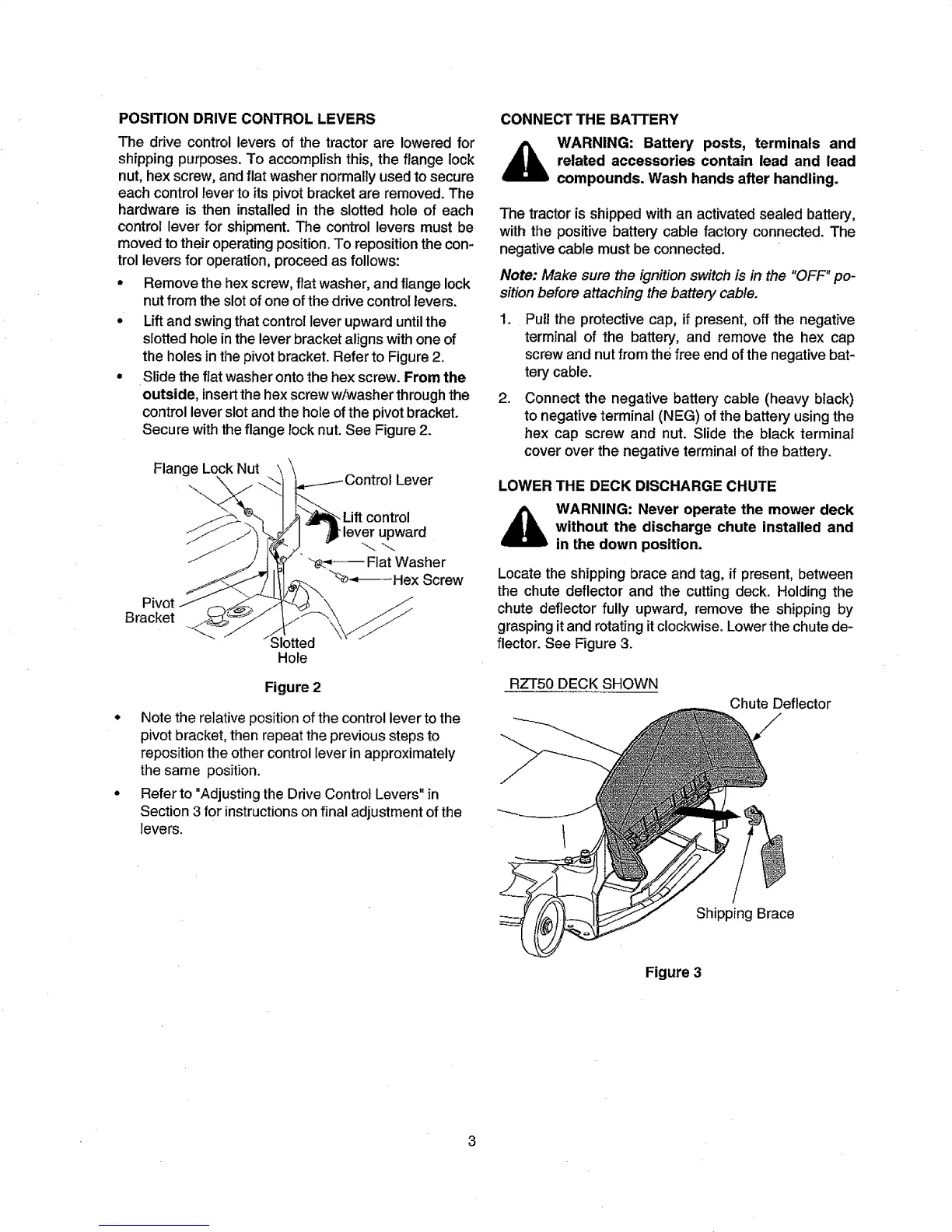

Locate the shipping brace and tag, if present, between

the chute deflector and the cutting deck. Holding the

chute deflector fully upward, remove the shipping by

grasping it and rotating it clockwise. Lower the chute de-

flector. See Figure 3.

RZT50 DECK SHOWN

Chute Deflector

Shipping Brace

Figure 3

3

Loading...

Loading...