Hydraulic System 1

27

5 Assembly of Hydraulic Pipes

1. Misalignment at joint by hose shall be within 2mm {0.079} on both sides of pipe.

2. Apply some oil to the O-ring and take caution not to fill out at assembly.

3. Apply some lubricant, MoS2-P, to the driving shaft spline for pump.

4. Handle with caution for entry of foreign matters to the pipe or mounting holes, etc. at assembly and

disassembly.

5. Make sure there is no oil leakage after assembly.

6. Follow below for assembly of the filter.

1) Clean the mounting face and apply some oil to the packing face of cartridge for lubrication.

2) Tighten with torque at 14.7 to 19.6 N•m {150 to 200kgf•cm, 10.85 to 14.5lbf•ft}.

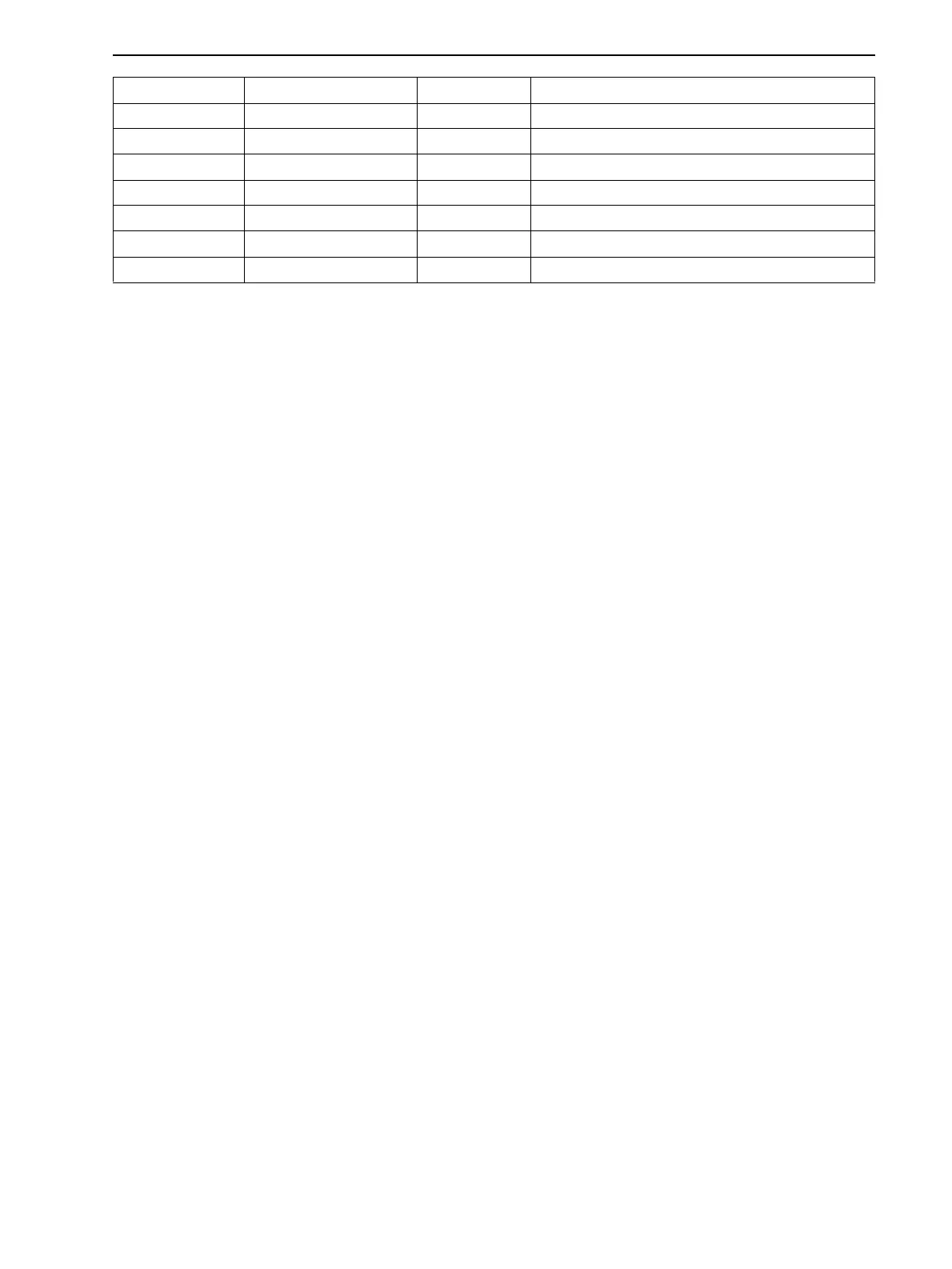

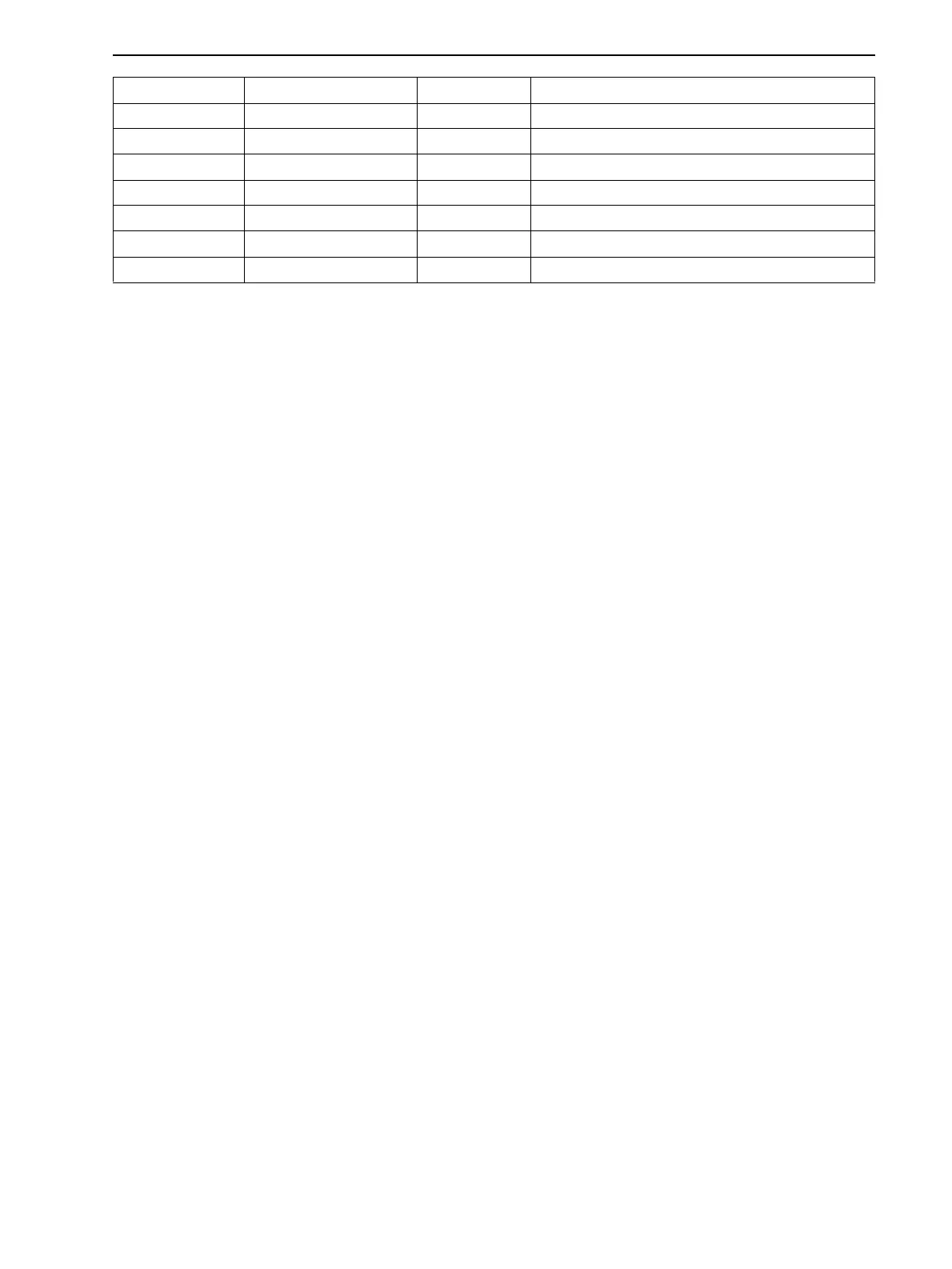

No. Parts Size Torque (N•m {kgf•cm, lbf•ft})

1 Bolt M8 19.6 to 21.6 {200 to 220, 14.46 to 15.9}

2, 3, 4 Bolt M10 39.2 to 44.1 {400 to 450, 28.9 to 32.5}

5 Bolt M14 118 to 132 {1200 to 1350, 86.8 to 97.6}

6 Plug G1/4 34 to 39 {350 to 400, 25.3 to 28.9}

7, 8 Plug G3/8 49 to 59 {500 to 600, 36.2 to 43.4}

9 Sleeve 84 to 93 {850 to 950, 61.5 to 68.7}

10, 11 Screw M8 15 to 18 {150 to 180, 10.85 to 13}

www.mymowerparts.com

K&T Saw Shop 606-678-9623 or 606-561-4983

Loading...

Loading...