Domestic Series 7000 Hydraulics

25

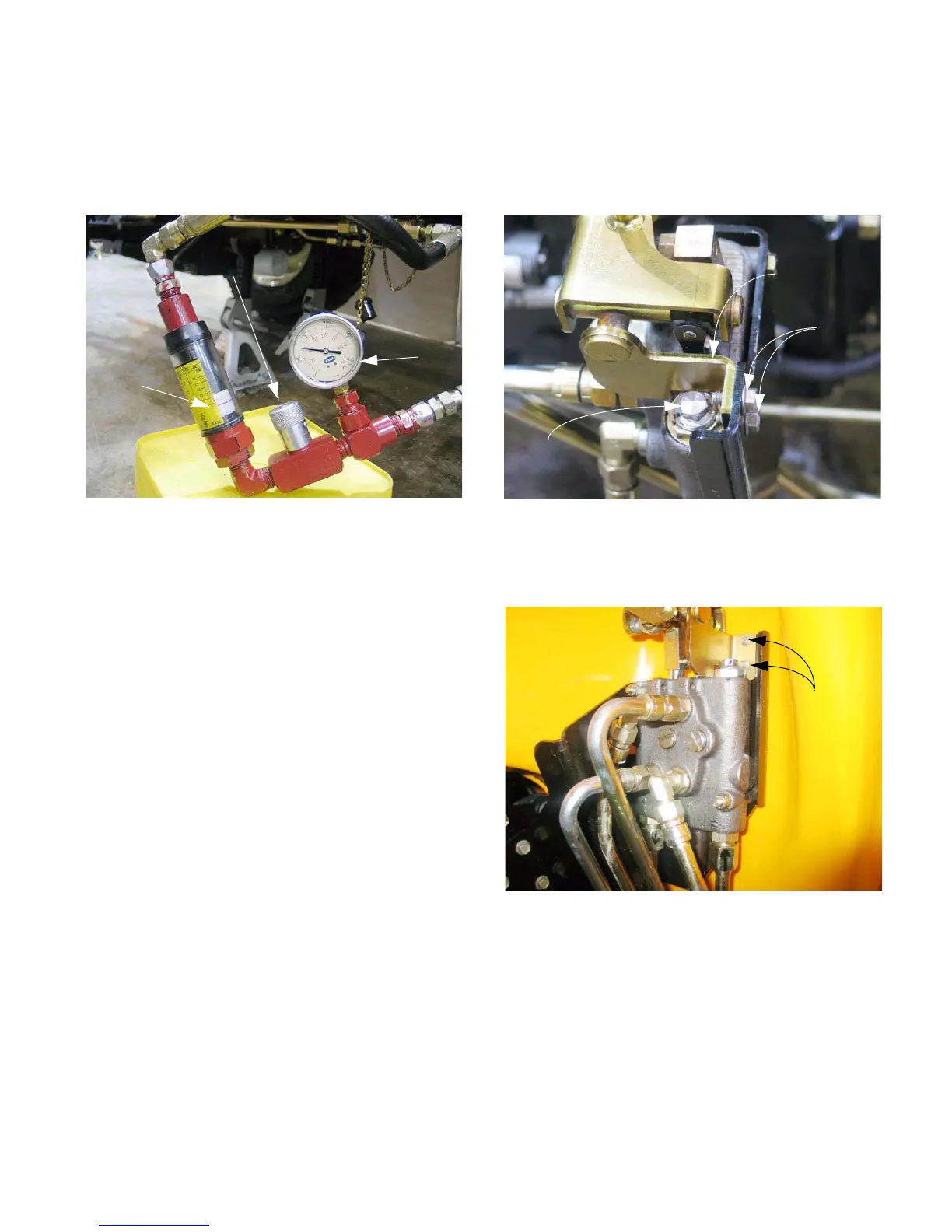

10.7. While holding the loader valve lever forward,

close the flow valve on the test kit. Because

there is a pressure relief feature in the loader

valve, the pressure should rise to 1,500 PSI (103

Bars) and hold steady. See Figure 10.7.

NOTE: Because of the relief feature built into the

loader valve, as pressure aproaches the relief

point of 1,500 PSI (103 Bars) more fluid will be

diverted to the return manifold. As more fluid is

diverted, the flow meter will show progressively

lesser readings. If the flow valve on the test kit

is closed completely, flow will stop completely.

CAUTION: If pressure rises substantially above

1,500 PSI (103 Bars) discontinue the test imme-

diately. Correct the pressure relief issue before

continuing.

10.8. If the pressure varies slightly in either direction,

the relief valve can be adjusted. It is located on

the top, outboard corner of the loader valve.

10.9. In order to adjust the relief valve, it is necessary

to remove the fenders. The fender removal pro-

cess is described in detail in the 2003 Cub Cadet

Technical Handbook, page 6-21 through page 6-

26.

Figure 10.7

Flow meter

at zero

Pressure

gauge at

1,500 PSI

(103 Bars)

Flow valve

closed

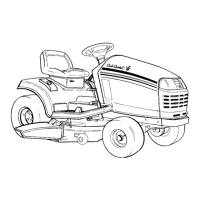

10.10.It is necessary to unbolt the pivot bracket

assembly from the loader valve in order to get a

wrench on the relief valve adjustment screw.

The pivot bracket can be unbolted using a 3/8”

wrench. See Figure 10.10.

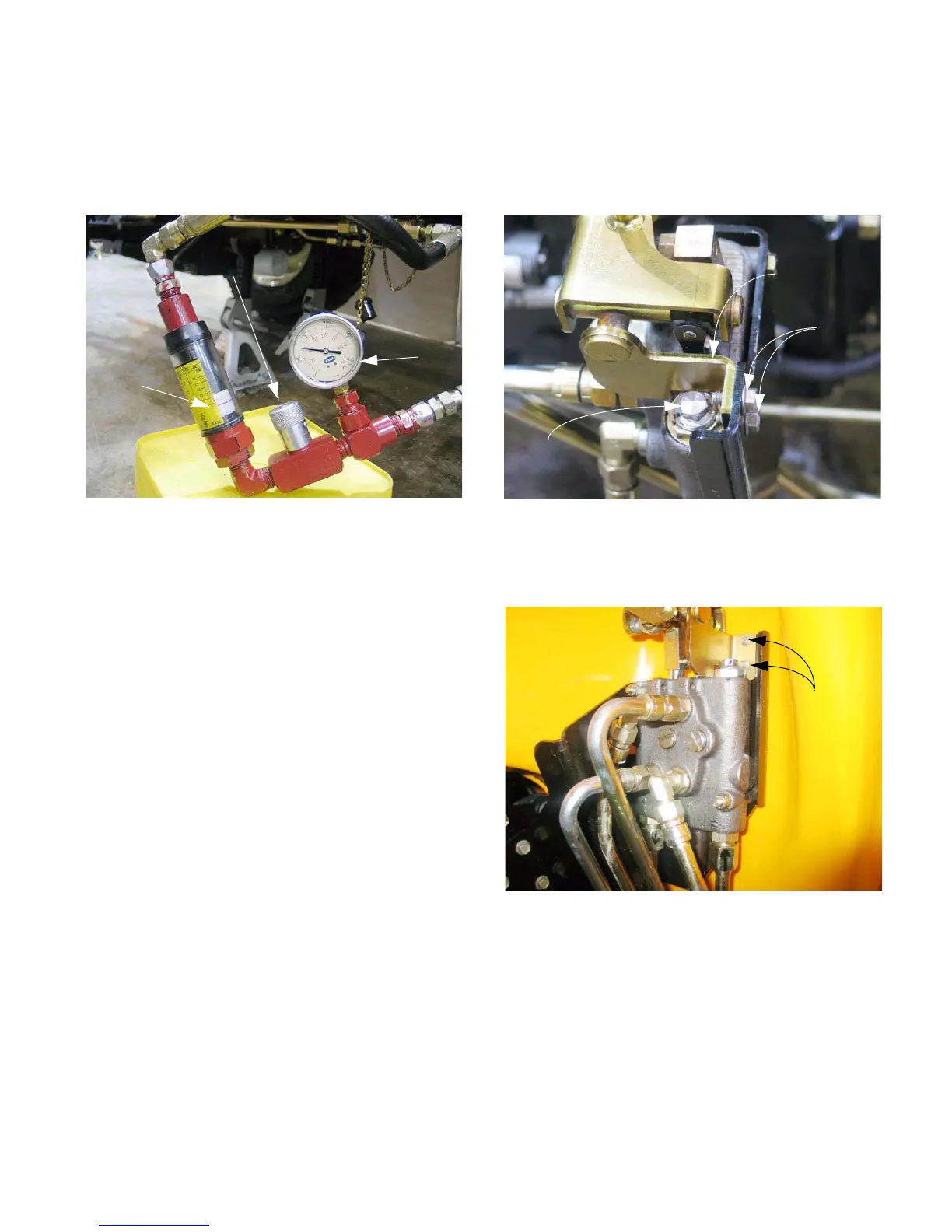

10.11. The pivot bracket bolts are inaccessible without

removing the fender. See Figure 10.11.

10.12.Once access is gained to the adjustment screw,

index the screw, jam nut, and housing using a

marker.

Figure 10.10

Releif valve

adjustment

screw

Pivot bracket

Pivot bracket

bolts

Figure 10.11

Pivot

bracket

bolts

Loading...

Loading...