Domestic Compact Electrical Systems

73

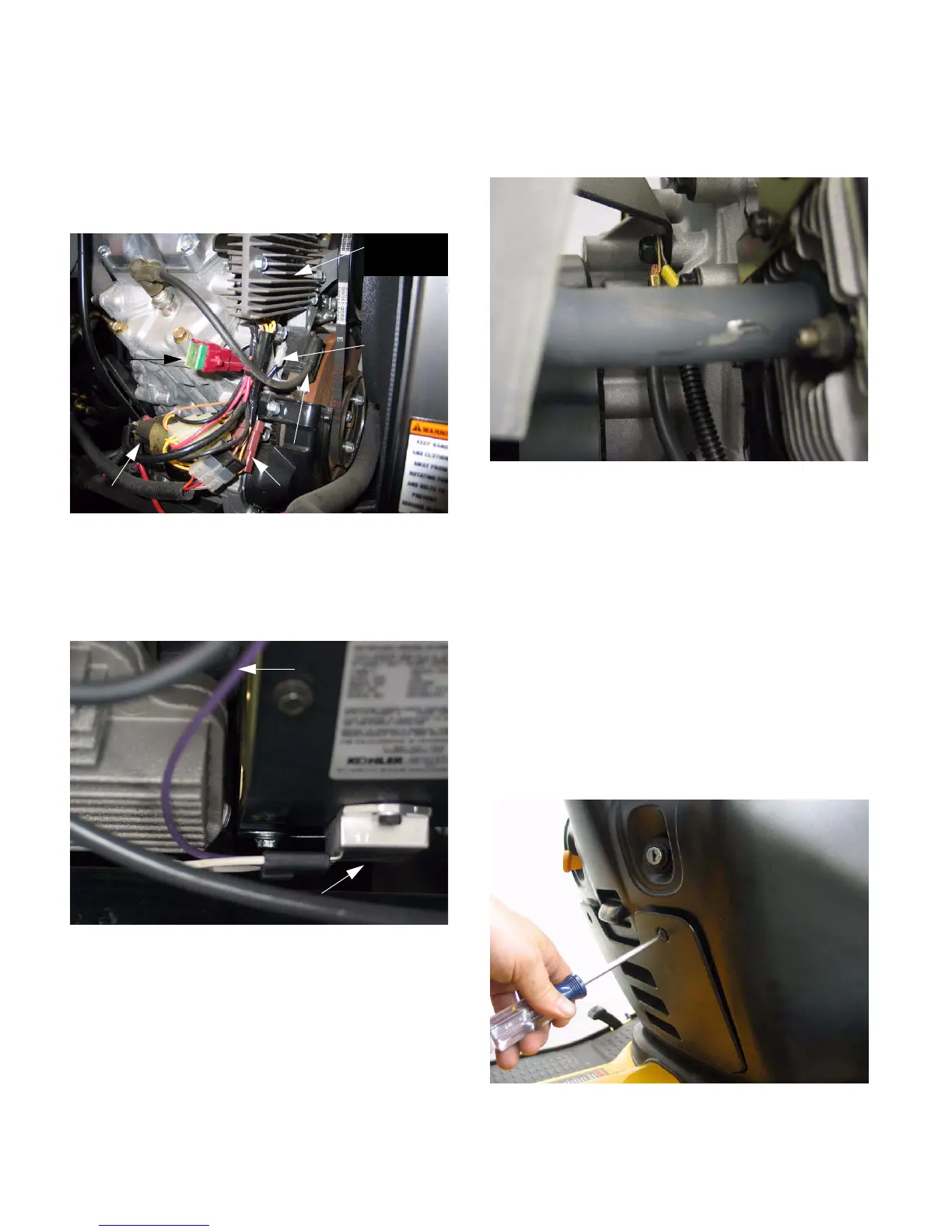

1.11. The gasoline engines use flywheel mounted

rotors and engine mounted stators to generate

A.C. current. The current is processed through

regulator-rectifier modules before being passed

to the main harness of the tractor.

See Figure 1.11.

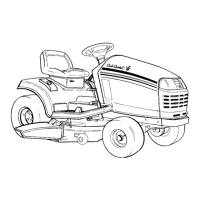

1.12. Systems vary slightly between engine manufac-

turers, but principles of operation are compara-

ble. See Figure 1.12.

1.13. Charging system diagnosis: Flywheel charging

systems can be diagnosed using the Briggs &

Stratton shunt (B & S part # 19468) or inductive

ammeter and DVOM. Charging systems on the

diesel engines are similar enough to automotive

designs that an automotive type AVR tester (eg.

Snap-On MT3750) can be a feasible alternative

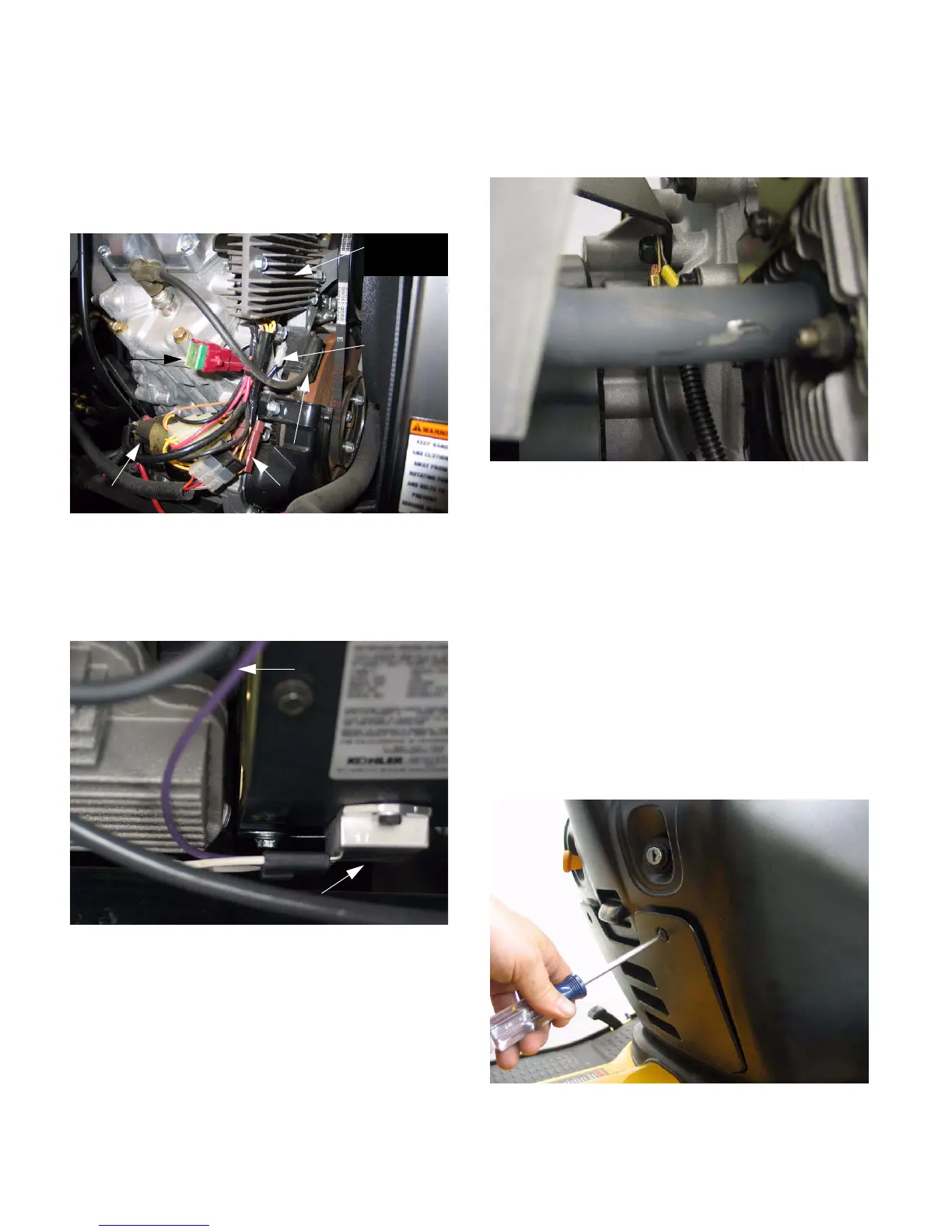

1.14. As with all electrical systems, do not neglect the

basics: clean connections and good ground

paths. See Figure 1.14.

2. COMPONENTS

2.1. The heart of the electrical system is in the dash

panel. It is some components are accessible

from beneath the hood, others may be reached

by removing the access panel. See Figure 2.1.

Figure 1.11

Kawasaki starter

Regulator

/ rectifier

Charging

circuit fusible

link (40A)

Mag.ground

(kill) wire

Connector(raw alternator power)

Magneto

Figure 1.12

Regulator / rectifier (Kohler engine)

Raw Alternator

out-put

Figure 1.14

Figure 2.1

Loading...

Loading...