Initial Startup 13

Cat. No. 01023094

Product Flow Calculations

The product flow rate depends primarily on feed water pressure, product water pressure, and temperature. All Series E

and M units have specified nominal flow rates based on 100 psig net pressure and 77°F temperature. However, in most

applications the temperature and pressure are lower, so the product flow rate is lower than the nominal flow rate. The

actual flow rate must be converted to flow under standard conditions, then compared to the initial performance (also con-

verted to standard conditions) to determine whether the system is still working properly.

To convert the data to standard conditions,

1. Measure the product flow. Example: 500 ml/min

2. Measure the feed pressure. Example: 175 psig

3. Measure the product pressure. Example: 35 psig

4. Subtract the product pressure from the feed pressure. Example: 140 psig

5. Divide the product flow by the result from step 4. Example: 500 / 140 = 3.57 ml/min/psi

6. Multiply the result from step 5 by 200. Example: 3.57 x 200 = 714 ml/min

7. Measure the temperature of the feed water, then determine the temperature correction factor from Table 1.

Example: At a temperature of 55°F , the factor is 1.54.

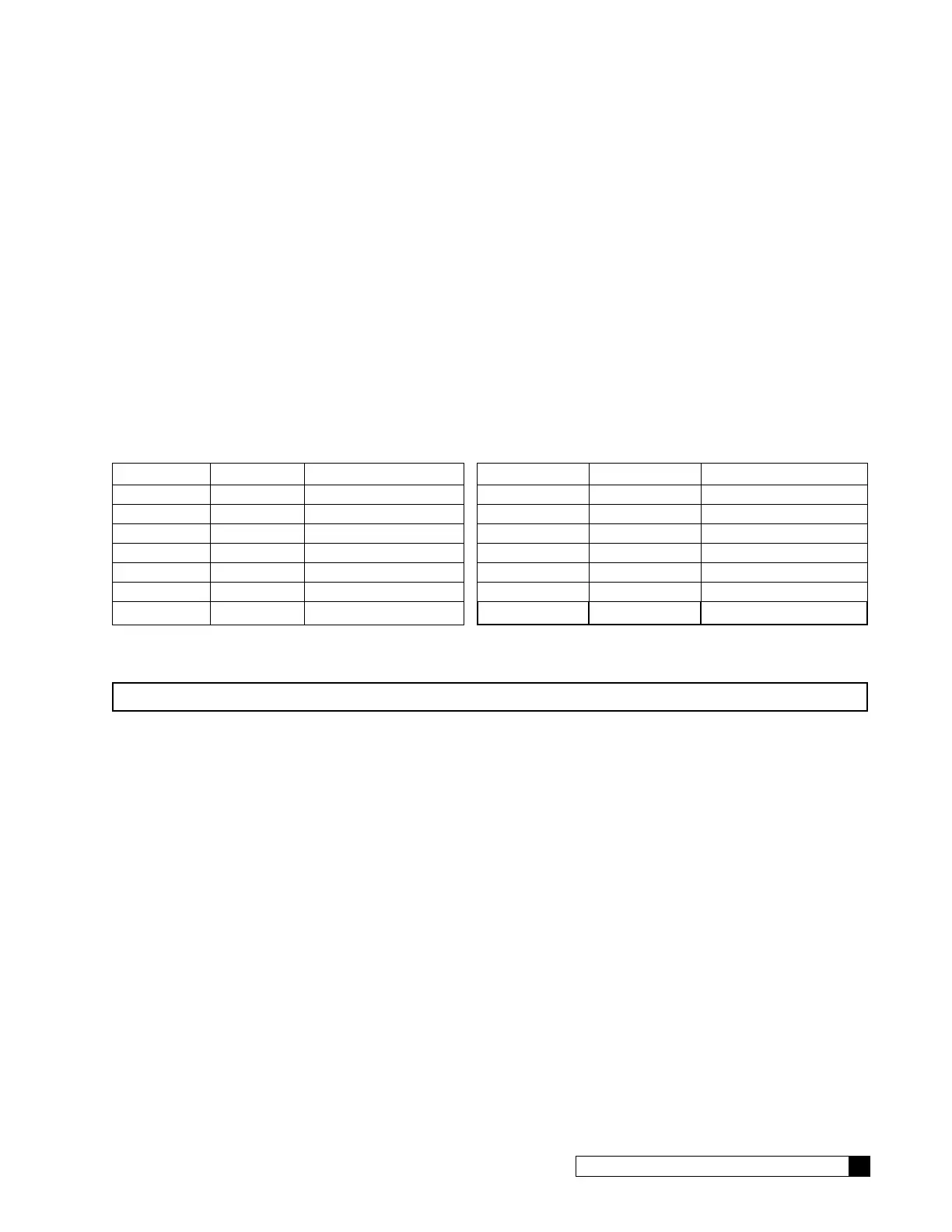

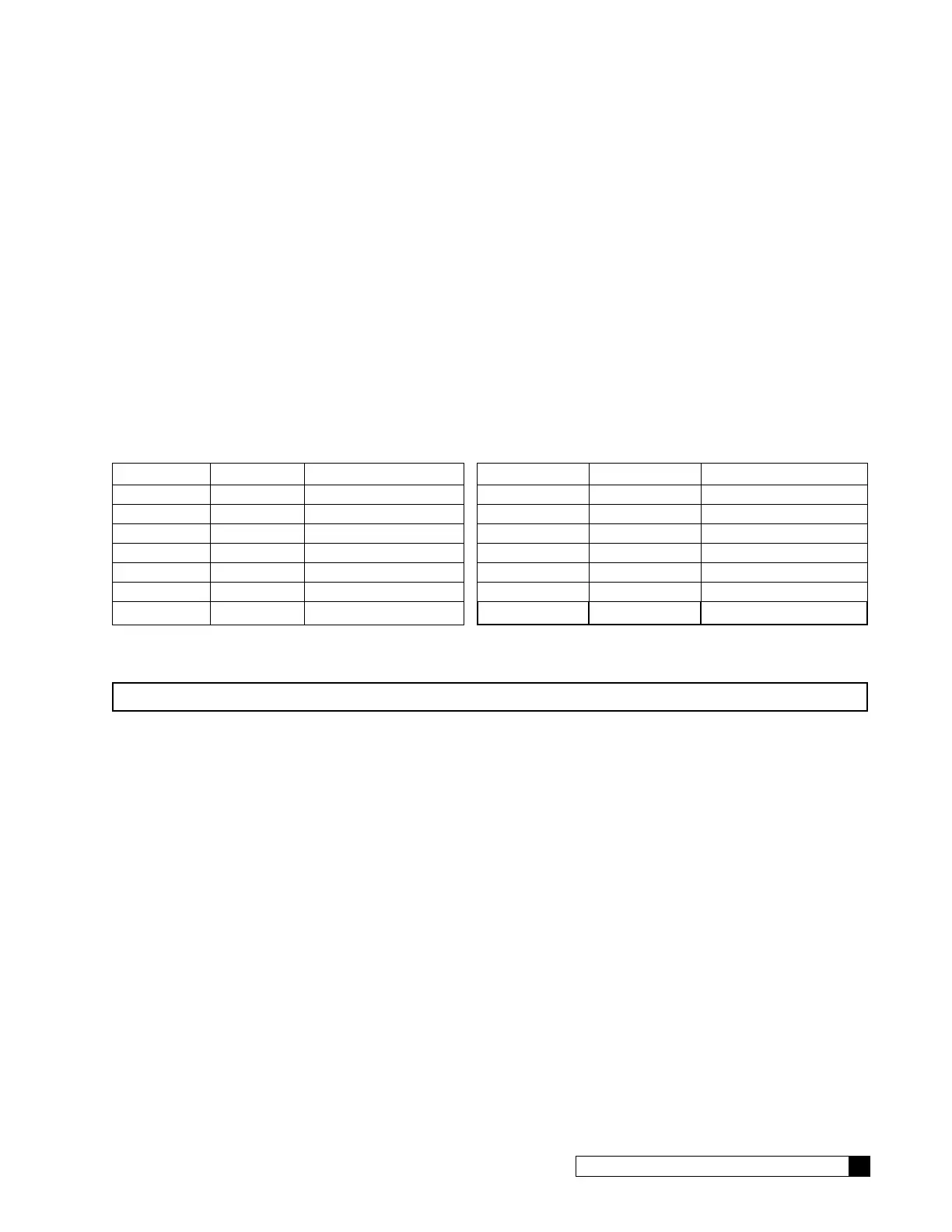

Temp. °F Temp. °C Correction Factor Temp. °F Temp. °C Correction Factor

40 4.4 2.12 75 24 1.04

45 6.7 1.90 80 27 0.95

50 10 1.71 85 29 0.86

55 13 1.54 90 32 0.79

60 16 1.39 95 35 0.72

65 18 1.26 100 38 0.66

70 21 1.14

Table 1. Temperature Correction Factors

8. Multiply the result of step 6 by the temperature correction factor. Example: 714 ml/min x 1.54 = 1099 ml/min.

NOTICE To convert ml/min to gallons per day, multiply by 0.38. For example, 1099 ml/min x 0.38 = 417 gpd.

9. Compare the current standardized flow to the initial standardized flow. If the flow has decreased by 10% or

more, it is time to clean the elements.

Example: If the initial standardized flow was 570 gpd, and the current standardized flow is 470 gpd, the flow has

decreased by 100 gpd, or 18% (100/570) = 0.18. The elements should be cleaned.

10. If the problem cannot be corrected with the troubleshooting guide and assistance is required, please have the

following information available when calling the Culligan dealer:

• Product flow rate

• Concentrate flow rate

• Feed pressure

• Product water quality

• Feed water quality

• Feed water temperature

• Prefilter outlet (and inlet if the optional prefilter inlet gauge was installed)

• Product pressure

Loading...

Loading...