18 Culligan® Series E2 Plus Reverse Osmosis

18 Cat. No. 01023094

Service and Maintenance

Serial Numbers

The Culligan units have a serial number located directly behind the electronic controller on the side panel. Do not remove

or destroy these serial number labels.

The serial number must be referenced if the RO system requires repairs or parts replacement under warranty.

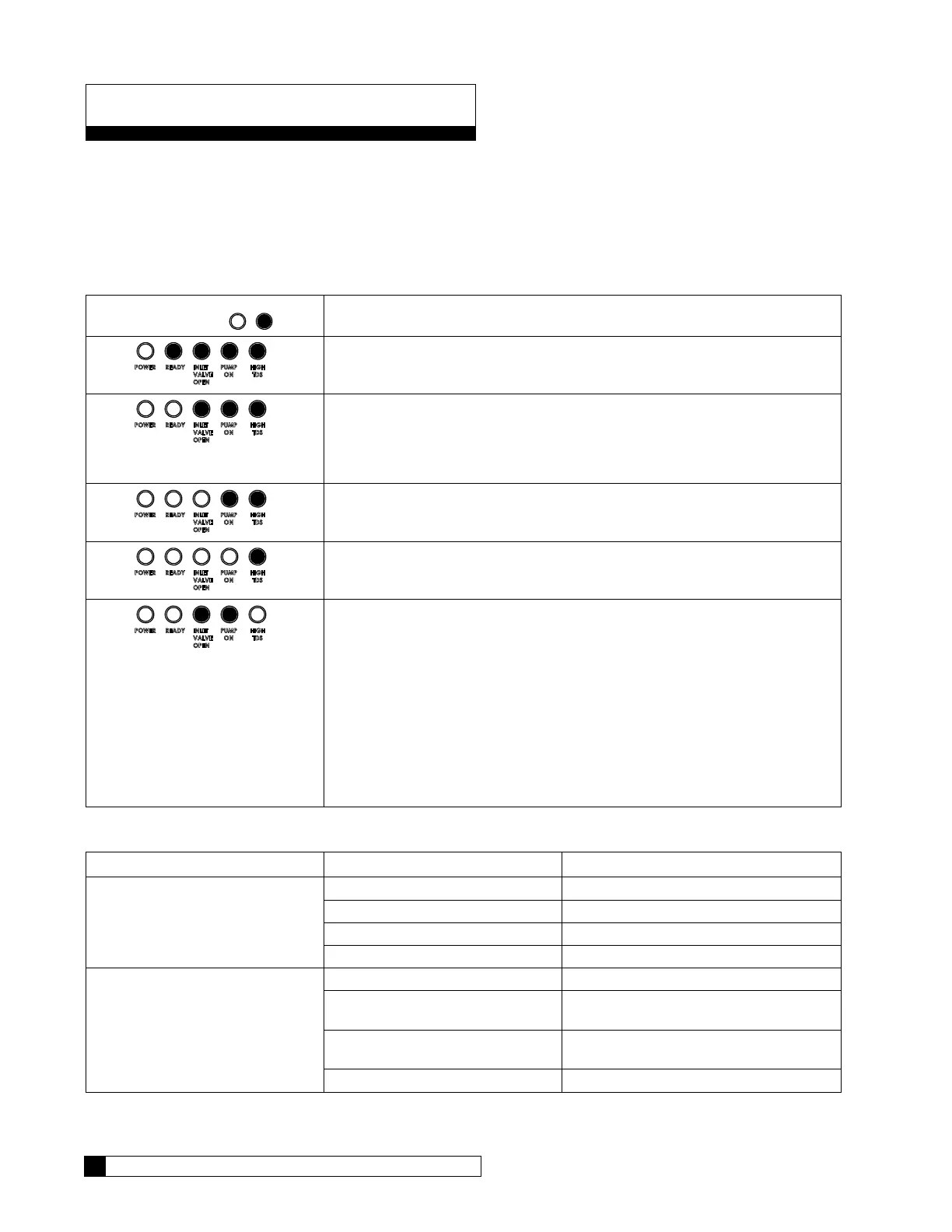

LED Status Indicators

LED Lights [

]

Solution

R HIGH

TDS

READY INLET

VALVE

OPEN

PUMP

ON

The system has power but is not making water because either the storage tank is

full or the pretreatment equipment is in pretreat lockout mode.

R HIGH

TDS

READY INLET

VALVE

OPEN

PUMP

ON

The system is in a one-hour delay period. These delay periods occur when either

the system has lost electrical power, or the system has lost sufficient incoming

water pressure. During this delay period you may push the RUN NOW button

located on the bottom of the control; the system will skip the remaining portion of

the delay.

R HIGH

TDS

READY INLET

VALVE

OPEN

PUMP

ON

The system is in start-up flush mode or timed flush mode. These modes usually

last one (1) minute.

R HIGH

TDS

READY INLET

VALVE

OPEN

PUMP

ON

The system is making RO water.

R HIGH

TDS

READY INLET

VALVE

OPEN

PUMP

ON

On systems equipped with an optional TDS probe, the system has stopped mak-

ing water because the product TDS has risen above the required water quali-

ty set by the DIP switches for greater than four (4) minutes. If the system has

stopped, it might indicate that the RO membrane has failed or there might be

some other problem with the system. After resolving the problem, restart the RO

by momentarily switching the power OFF and then back ON. When the Pow-

er and Ready lights are ON, you can press the RUN NOW button. The system

should begin to produce RO water. Use a handheld TDS meter to measure the

TDS of the product water. If it remains above the specified threshold, the system

will turn back off after approximately four (4) minutes.The system will continue

running if you unplug the TDS meter from the CP+ controller board or specify a

DIP switch setting that corresponds to a higher TDS threshold level.

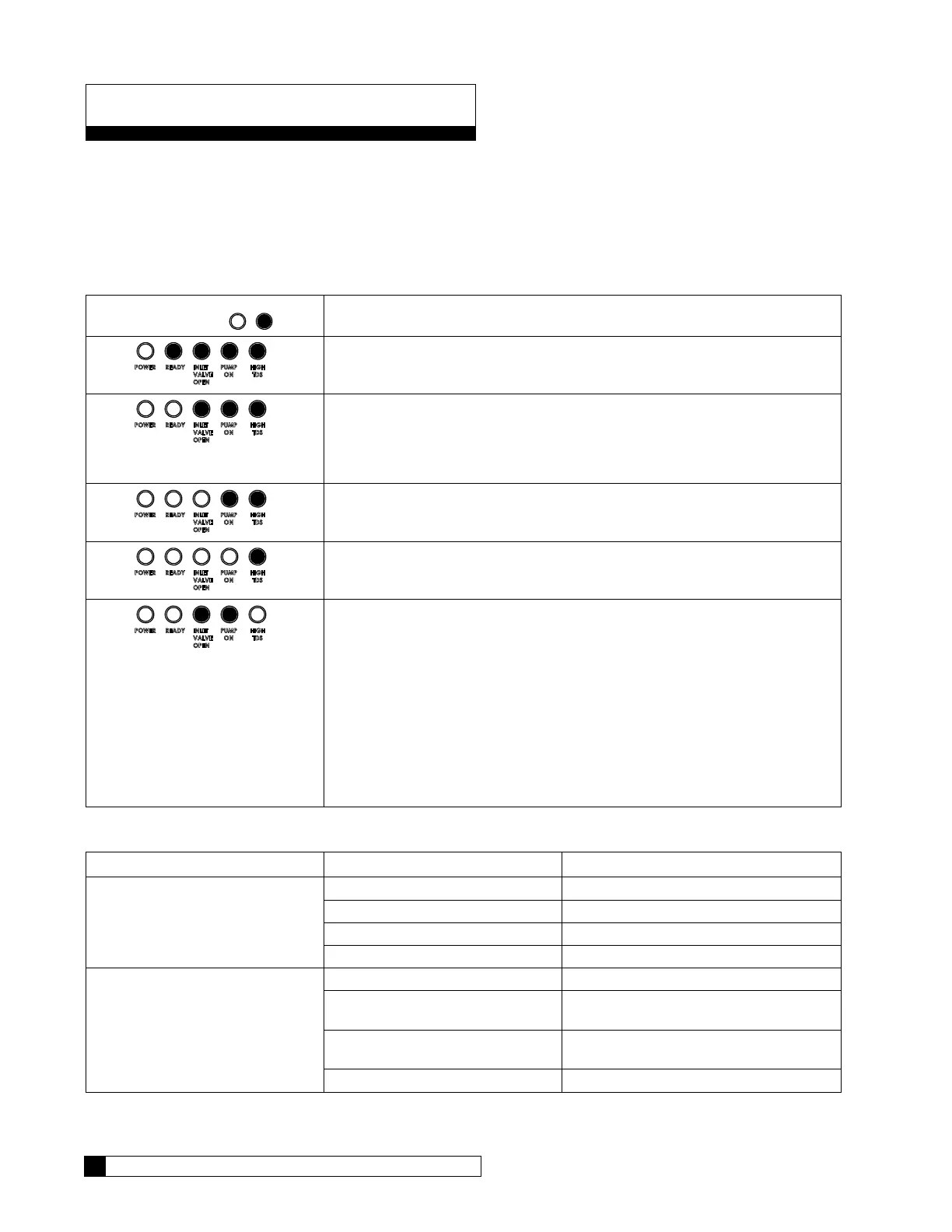

Troubleshooting

Problem Probable Cause Solution

1. Unit does not start. A. No power to unit. A. Check circuit breaker.

B. Low feed pressure. B. Correct low pressure condition.

C. Inlet solenoid failure C. Replace solenoid

D. Prefilter fouled. D. Replace cartridge

2. Unit running but not holding

high pressure.

A. Pump malfunction. A. Replace pump.

B. System pressure control valve

malfunction.

B. Replace valve.

C. Concentrate flow too high. C. Check and adjust concentrate flow, re-

place tubing on A.

D. Product flow too high. D. Test modules.

Loading...

Loading...