9

CONDUIT CENTERLINE BENDING RADII

ASSEMBLY & OPERATING INSTRUCTIONS – 254 CONDUIT BENDER

(CONTINUED)

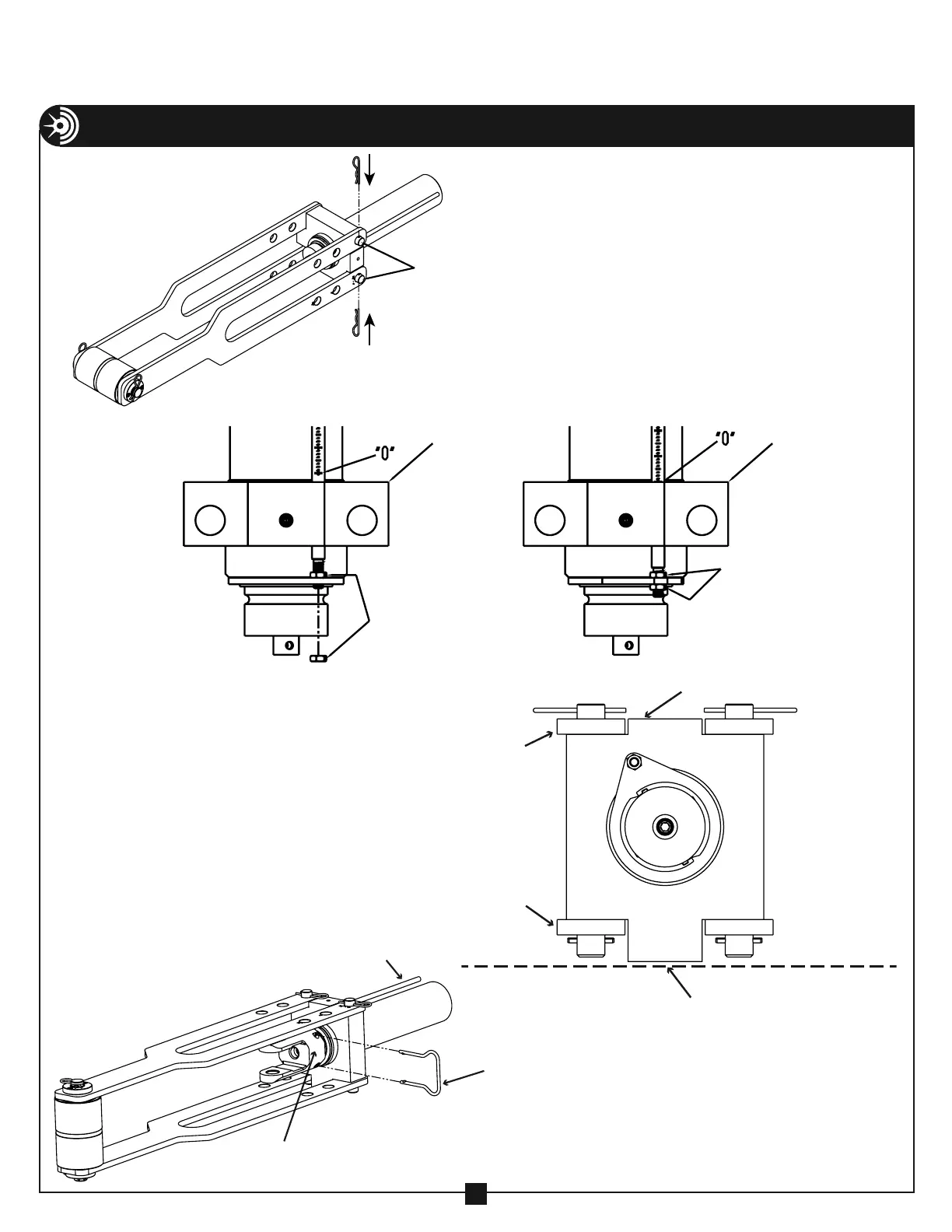

5. Adjust gauge rod such that gauge reads

zero when the cylinder is fully retracted.

NOTE: To adjust gauge rod, loosen

gauge rod adjusting nuts (see Figure

9A) and adjust rod such that zero (ø) is

flush with the top of the cylinder block

(see Figure 9B).

4. Place the hydraulic cylinder with the cylinder

mounting block between the frame sides as

shown in Figure 9. Insert the two cylinder

block pins into the appropriate frame side

holes for the size of conduit to be bent and

secure each with a spring clip.

NOTE: The hydraulic cylinder with mounting

block in Figure 9 is shown pinned in the

position for bending 4" conduit. The frame

side holes are marked to indicate where to

pin the mounting block for each size.

FIGURE 9

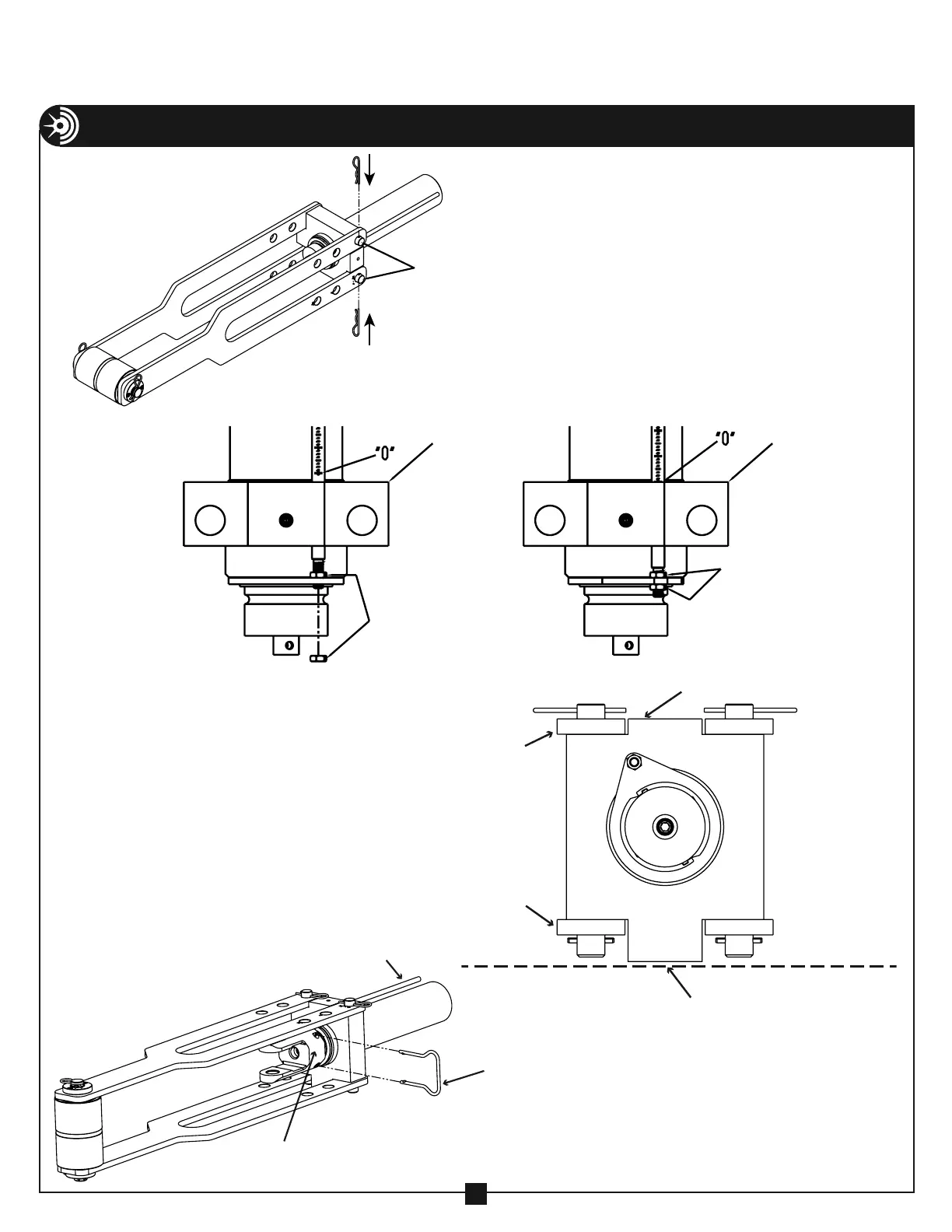

6. Rotate the frame and hydraulic

cylinder so the long side of the

cylinder mounting block is resting

on the floor (See Figure 9C). Then

place the clevis onto the end of the

hydraulic cylinder and secure with the

clevis retaining clip (see Figure 9D).

GAUGE ROD

CLEVIS

RETAINING

CLIP

CLEVIS

FIGURE 9C

SHORT SIDE OF THE

CYLINDER MOUNTING BLOCK

FRAME SIDE

FRAME SIDE

LONG SIDE OF THE

CYLINDER MOUNTING BLOCK

FLOOR

FIGURE 9D

CYLINDER

BLOCK

CYLINDE

BLOCK

ADJUSTING

NUTS

ADJUSTING

NUTS

CYLINDER

BLOCK PINS

FIGURE 9B

FIGURE 9A

Loading...

Loading...