CURTMFG.COM

•

PRODUCT SUPPORT: 877.287.8634

•

25474-INS-RB

•

07/25/2022

•

ECN9755

•

PAGE 2

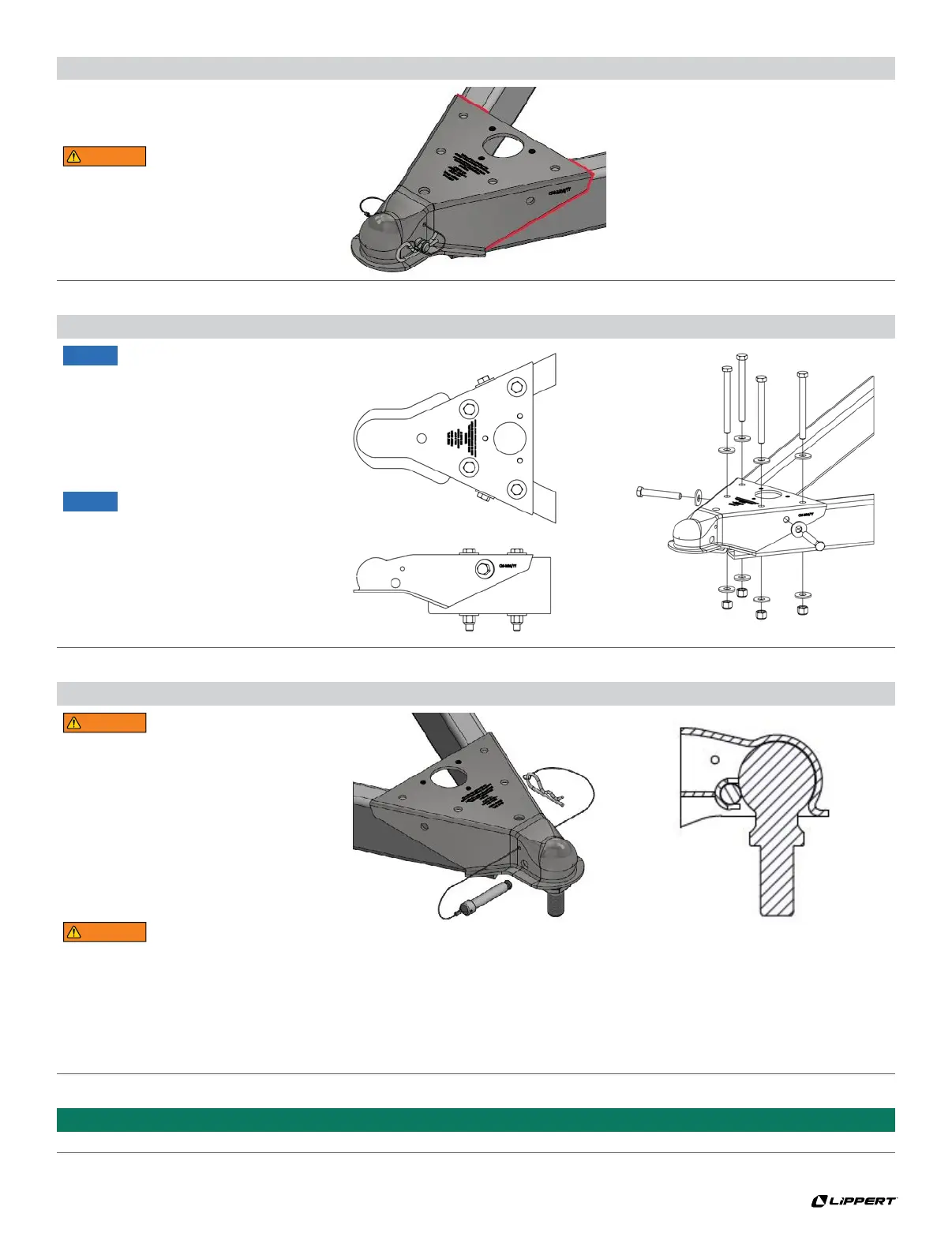

Step 1A - Weld-On Application

Coupler should be fully welded to the frame as

indicated by the red lines with a minimum weld

size of 3/16” by an AWS certified welder.

WARNING

Weld surfaces should be cleaned and prepped

prior to welding. Failure to properly prep

parts prior to welding could result in coupler

separation causing property damage,

serious bodily injury, and / or death.

Step 2

WARNING

Only use the pin & clip provided with

the coupler. Using an alternate pin & clip

could result in property damage, serious

bodily injury, and / or death.

To couple: Remove the pin & clip from the pin

guide hole. Lower the coupler over the trailer

ball until the ball is fully seated in the ball

pocket. Insert the provided pin through

the pin guide hole and fasten the clip

through the end of the pin.

When the ball is fully seated, if the pin

does not pass through the coupler

completely, DO NOT TOW.

To uncouple: Block the trailer's wheels.

Remove the pin & clip from the pin guide

hole and raise the trailer off of the trailer ball.

Place the pin & clip back into the pin guide hole

TOWING BASICS & SAFETY INFORMATION

For information on safely towing your trailer, visit curtmfg.com/understanding-towing.

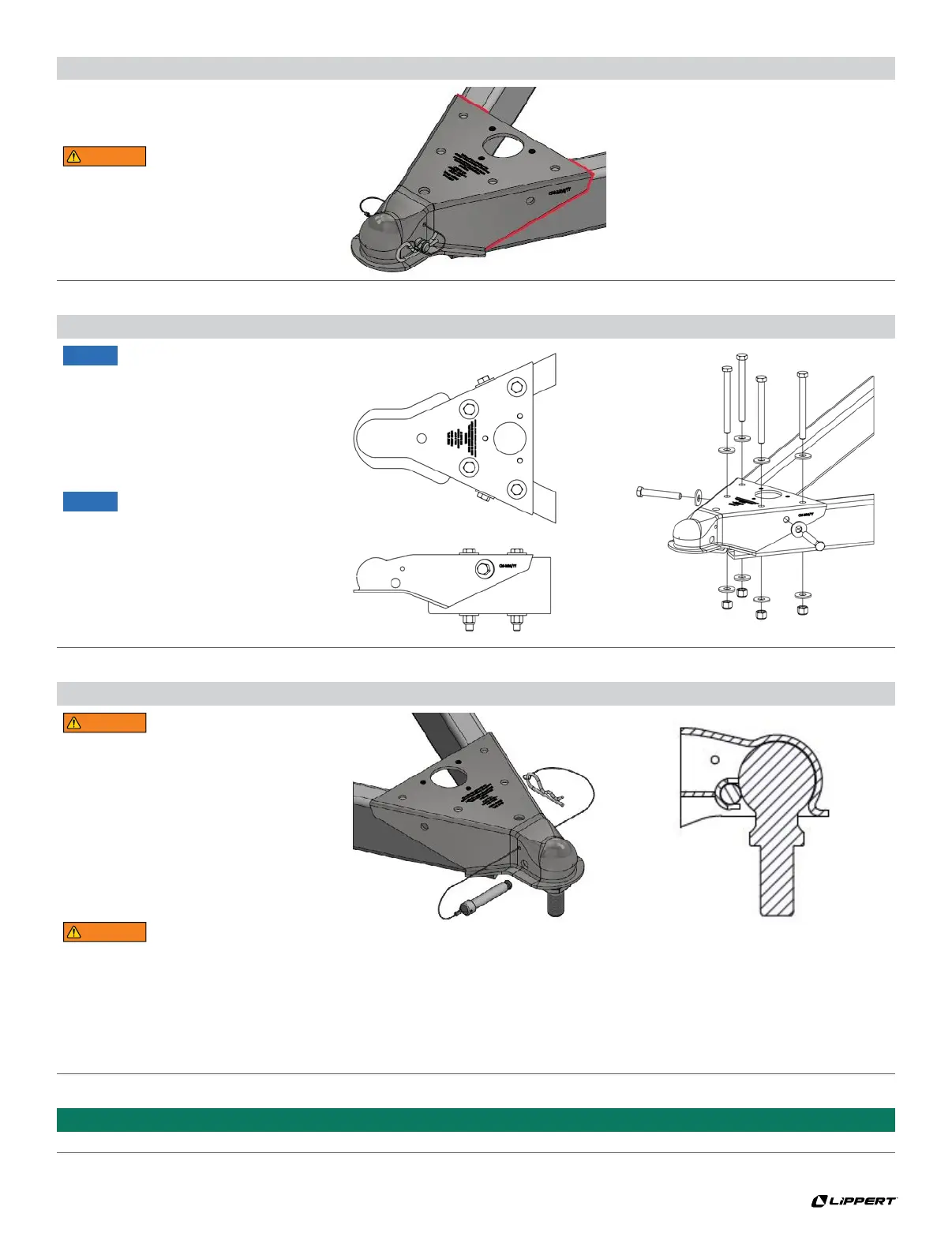

Step 1B - Bolt-On Application

Coupler should only be used

with 50 degree trailer tongues.

Bolt the coupler to the trailer tongue using

grade 5 hardware (not included). The hardware

needed to install the coupler include six 1/2"

bolts, six 1/2" lock nuts and twelve washers.

NOTICE

The bolt length should extend

a minimum of three threads

beyond the lock nut when torqued.

Torque hardware to 55 ft-lbs.

Loading...

Loading...