2 — INSTALLATION AND WIRING

1212 & 1212P Manual - Sep 2019

Return to TOC

pg. 8

THROTTLE WIRING

Either a 3-wire potentiometer throttle or a voltage throttle can be used with the 1212/1212P controller.

e controller can accept a single-ended, inverse single-ended, wigwag, inverse wigwag, or unipolar

input signal from the throttle, depending on how the rottle Type parameter is programmed; see

page 18.

rottle wiring is described in the following text. If the throttle you are planning to use is not covered,

contact the Curtis office nearest you.

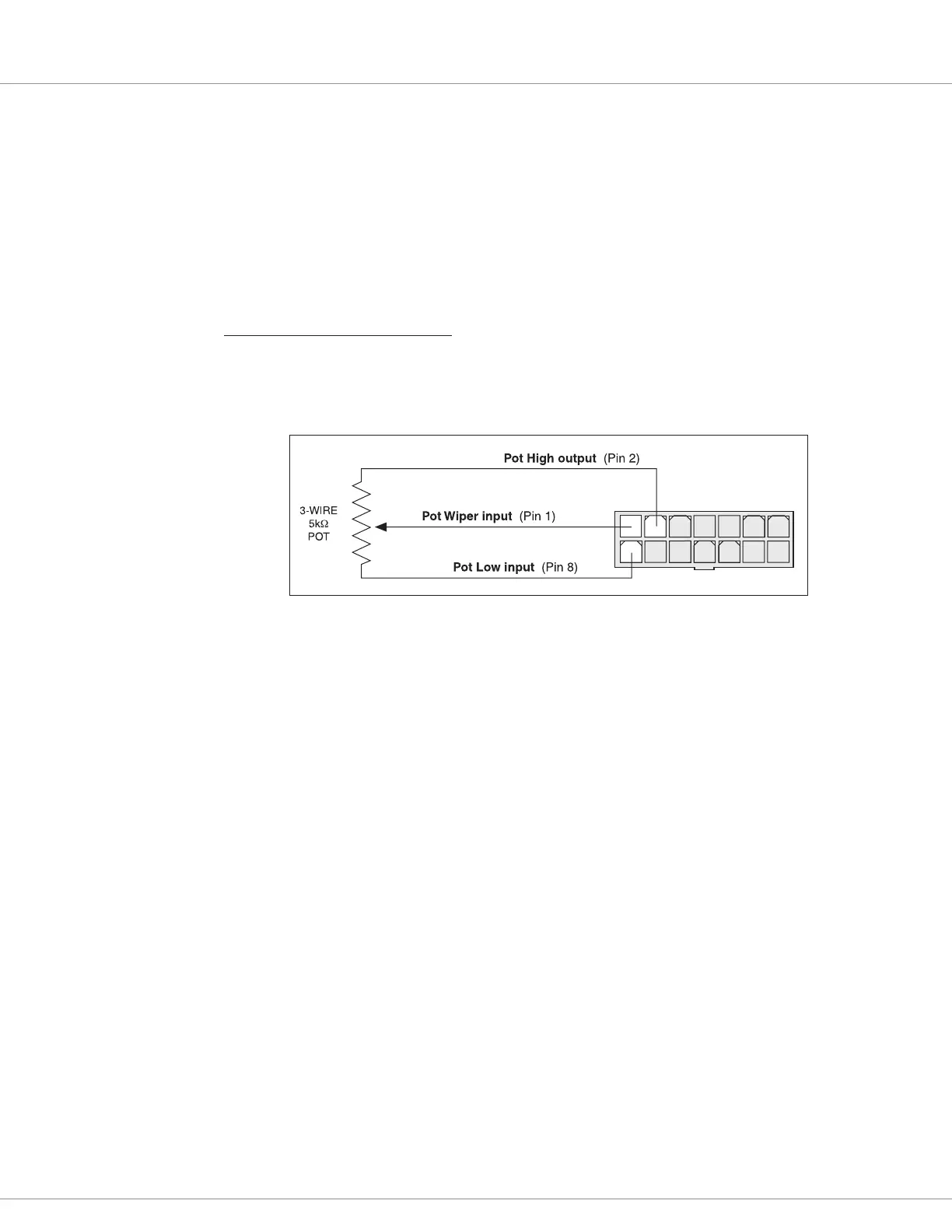

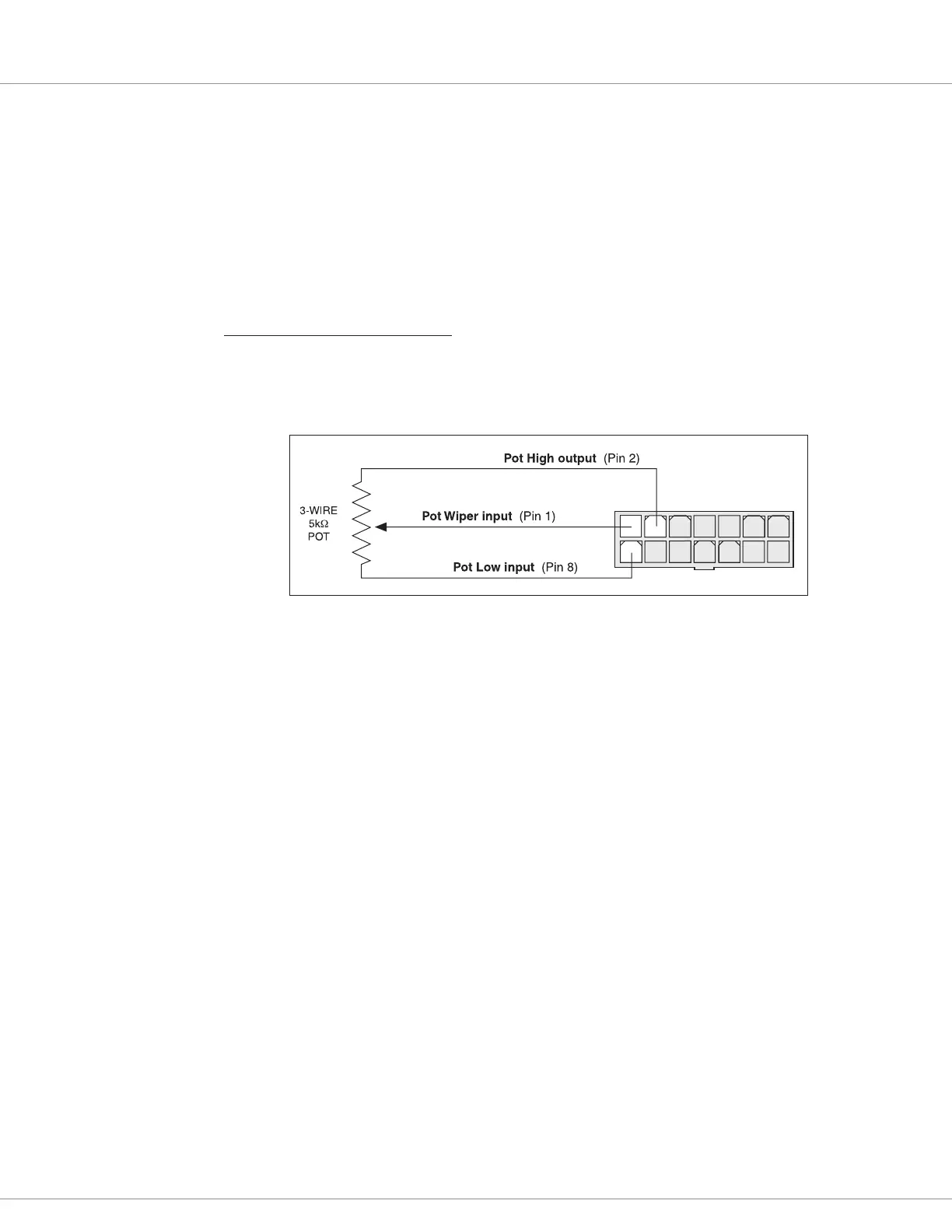

5kΩ, 3-Wire Potentiometer

A 5kΩ, 3-wire potentiometer is shown in the wiring diagrams (Figures 3a and 3b) as well as in

Figure 4. With this throttle, the controller can be programmed for a rottle Type 0–4 input signal;

see page 18.

1234567

8910 11 12 13 14

Figure 4

Wiring for 3-Wire,

5K

Ω

Potentiometer

rottle.

For wigwag, inverted wigwag, and unipolar applications, the pot can be correctly centered within the

controller’s neutral band by using the throttle autocalibration feature (see page 20).

e controller provides full pot fault protection against open or shorted wires anywhere in the

throttle assembly. e overall pot resistance should be 4.3 to 7.0 kΩ. Values outside this range will

trigger a fault condition. If a pot fault occurs while the vehicle is moving, the controller will decelerate

the vehicle to a smooth stop using the decel rate set by the Key O Decel parameter. If the fault is

corrected while the throttle is still applied, an HPD fault will be issued and driving is disabled until

throttle is reduced to neutral.

Loading...

Loading...