GENERAL INFORMATION & ROUTINE MAINTENANCE

Page A-2

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings

In order to prevent damage to the bat-

tery charger transformer, blow water

from charger with compressed air. Allow sufficient time (1 - 2

hours) after washing the vehicle for the transformer to dry

before operating the charger.

PMC Controller should be covered during washing of the vehi-

cle.

ROUTINE MAINTENANCE

Some maintenance items must be serviced

more frequently on vehicles used under severe

driving conditions.

This vehicle will give years of satisfactory service provid-

ing it receives regular maintenance. Refer to the Periodic

Service Schedule for appropriate service intervals (Ref

Fig. 19 on page A-10). Refer to Lubrication Points for

appropriate lubrication locations (Ref Fig. 4 on page A-

2).

Do not use more than three (3) pumps

of grease in each grease fitting at any

one time. Excess grease may cause grease seals to fail or

grease migration into areas that could damage components.

Putting more than three pumps of grease in a grease fit-

ting could damage grease seals and cause premature

bearing failure.

REAR AXLE

The only maintenance to the rear axle for the first five

years is the periodic inspection of the lubricant level. The

rear axle is provided with a lubricant level check/fill plug

located on the bottom of the differential. Unless leakage

is evident, the lubricant need only be replaced after five

years.

Checking the Lubricant Level

With the vehicle on level ground, clean the area around

the check/fill plug and remove plug. The correct lubricant

level is just below the bottom of the threaded hole. If

lubricant is low, add as required. Add lubricant slowly

until lubricant starts to seep from the hole. Install the

check/fill plug. In the event that the lubricant is to be

replaced, the vehicle must be elevated and the oil pan

removed or the oil siphoned out through the check/fill

hole (Ref Fig. 5 on page A-2).

BRAKES

Service brakes in accordance with the Perodic Service

Schedule (Ref Fig. 19 on page A-10). Lubricate brake

bushes and linkage (Ref Fig. 6 on page A-3).

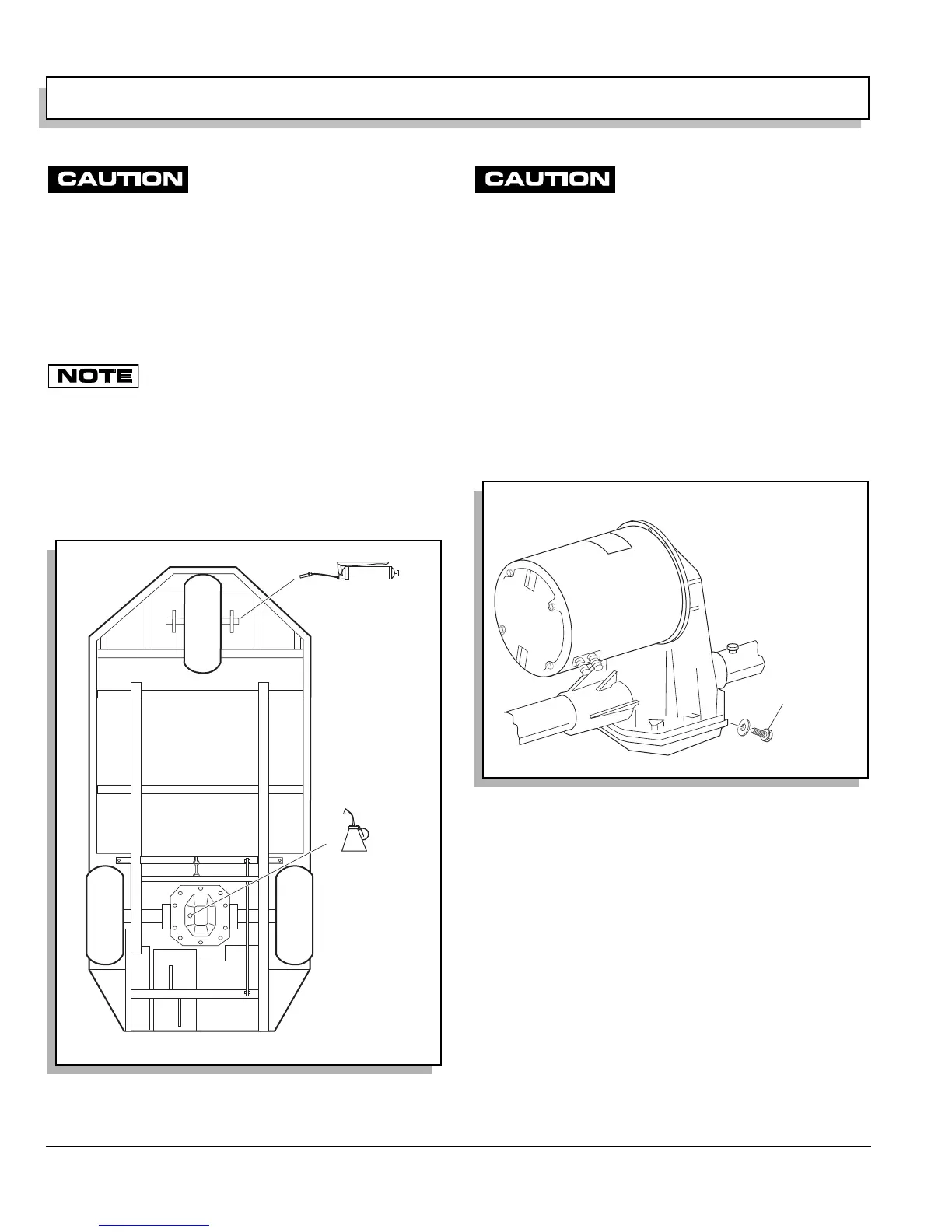

Fig. 4 Lubrication Points

Wheel bearings

and fork pivot

View from underside of vehicle

Rear axle

check and

fill

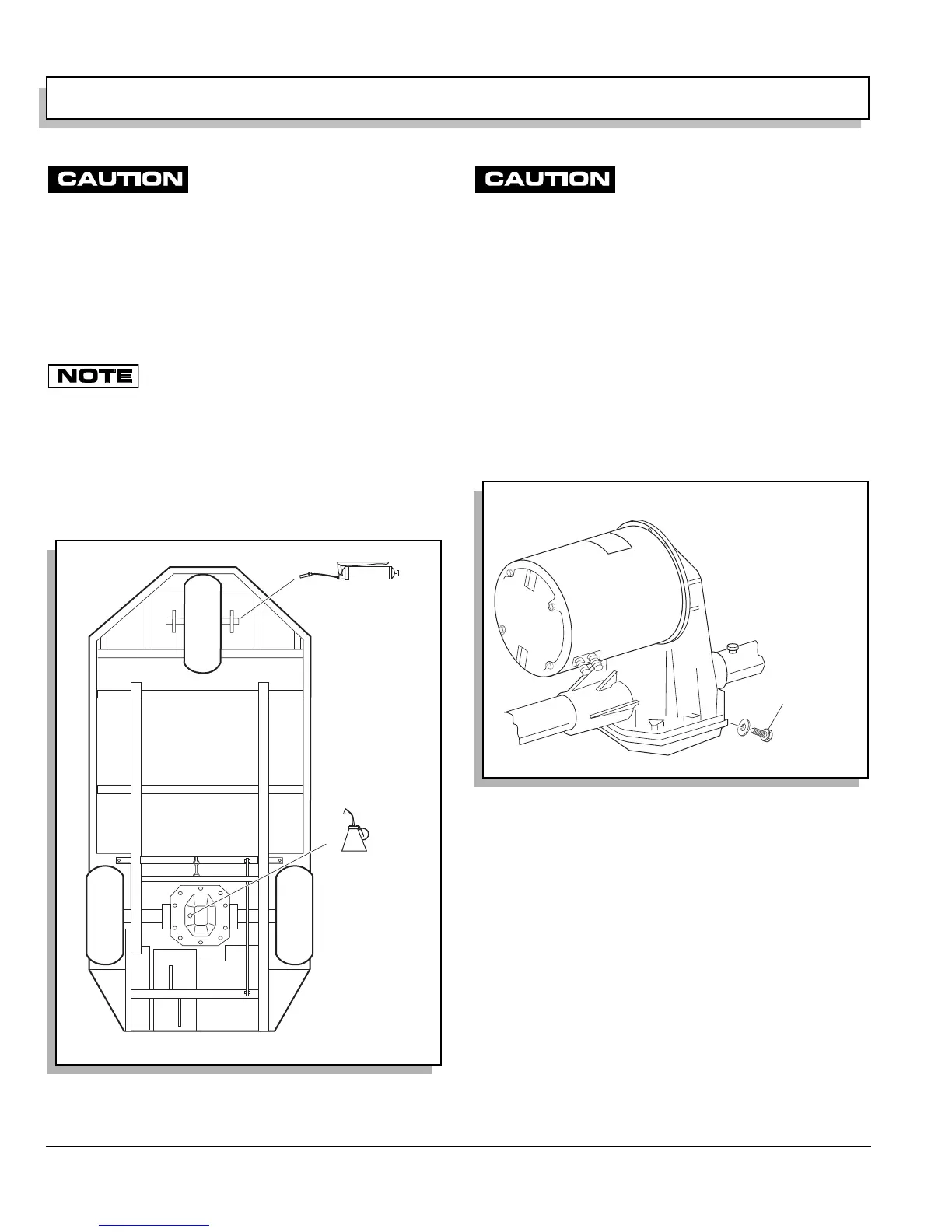

Fig. 5 Rear Axle Lubricant Check and Fill

Check/Fill Plug

Loading...

Loading...