www.cuttermasters.com - Toll Free (800) 417 2171

CUTTERMASTER Professional CM-01P User’s Manual

Page 17

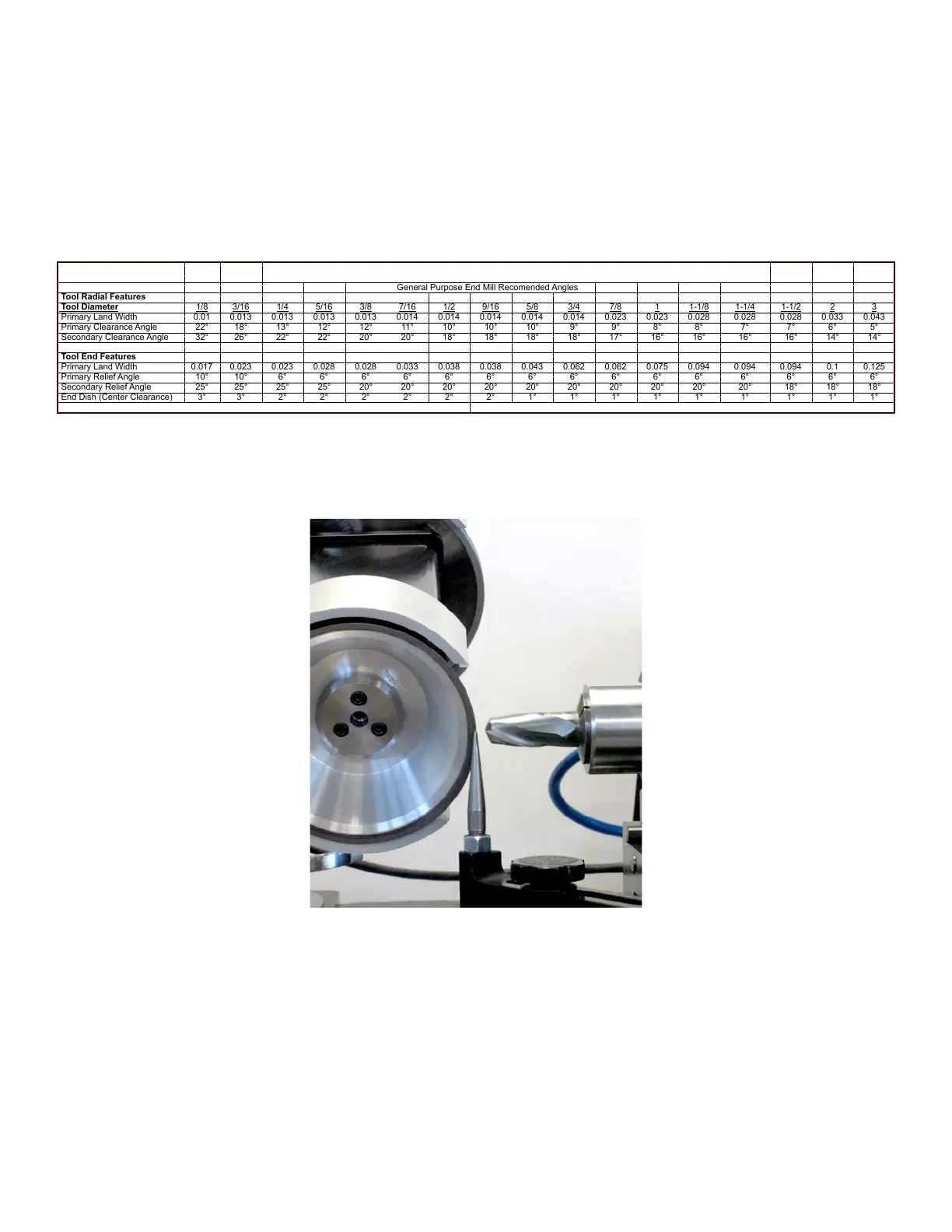

angle chart on the front of the machine as a guide [Figure 6].

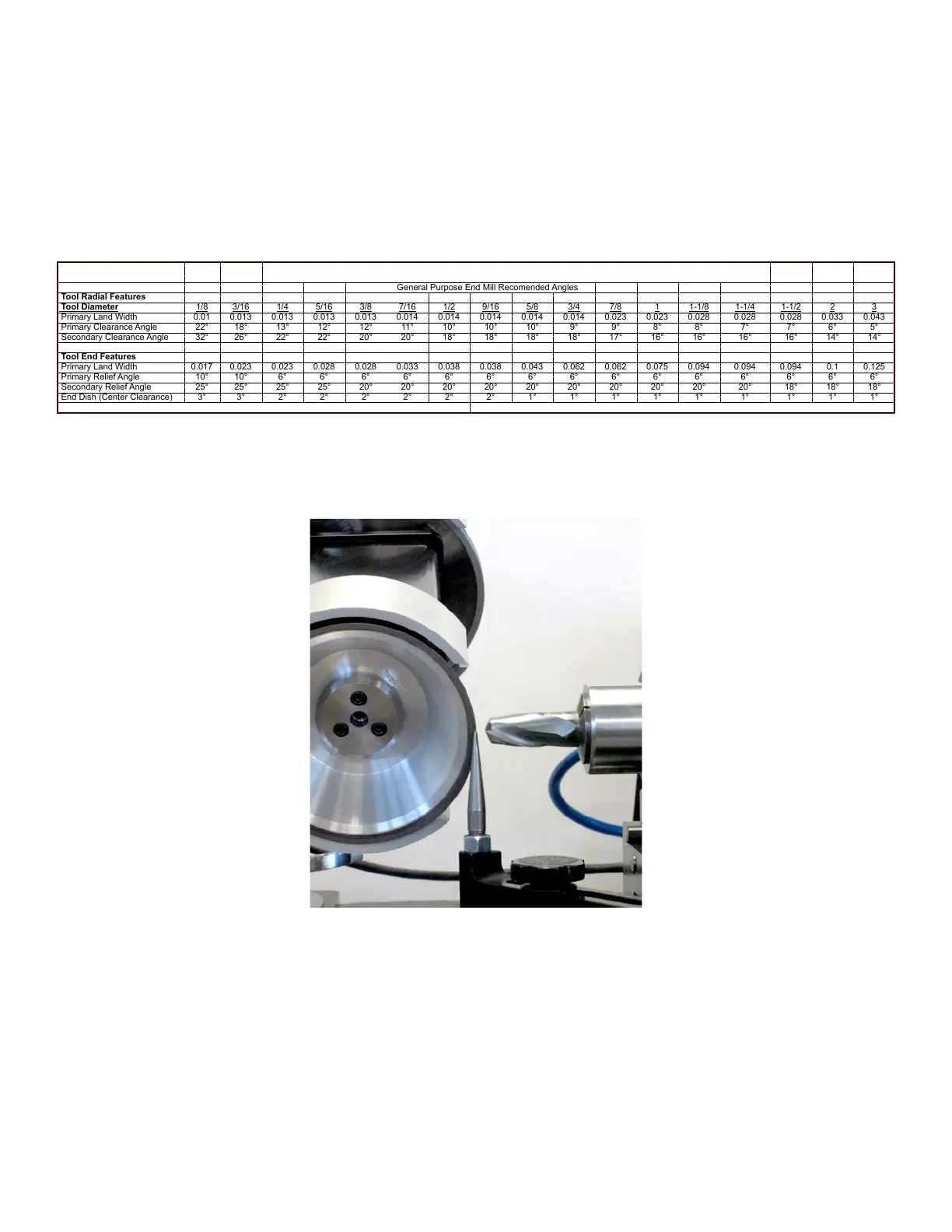

Raise or lower the motor so that the face of the wheel, at its mid point is as close as possible to the

tip of the tool rest. This is important to get the desired angle [Figure 7].

Oncethemachineattitudeisset,turnonthemotorandsetthelipoftheuteonthetoolrestupnear

the shank then bring the wheel in to gently touch the tool using the y axis feed dial.

It is advisable to set a magnetic back dial indicator on the y axis table to track the depth of cut.

When the wheel touches the tool, set the dial indicator to zero and then draw the tool on the tool rest

Figure 7. Wheel Positioning in Relation to

Tool Rest

Figure 6. CUTTERMASTER Professional Resharpening Guide

Tool Diameter 1/8 3/16 1/4 5/16 3/8 7/16 1/2 9/16 5/8 3/4 7/8 1 1-1/8 1-1/4 1-1/2 2 3

Primary Land Width 0.01 0.013 0.013 0.013 0.013 0.014 0.014 0.014 0.014 0.014 0.023 0.023 0.028 0.028 0.028 0.033 0.043

Primary Clearance Angle 22° 18° 13° 12° 12° 11° 10° 10° 10° 9° 9° 8° 8° 7° 7° 6° 5°

Secondary Clearance Angle 32° 26° 22° 22° 20° 20° 18° 18° 18° 18° 17° 16° 16° 16° 16° 14° 14°

Primary Land Width 0.017 0.023 0.023 0.028 0.028 0.033 0.038 0.038 0.043 0.062 0.062 0.075 0.094 0.094 0.094 0.1 0.125

Primary Relief Angle 10° 10° 6° 6° 6° 6° 6° 6° 6° 6° 6° 6° 6° 6° 6° 6° 6°

Secondary Relief Angle 25° 25° 25° 25° 20° 20° 20° 20° 20° 20° 20° 20° 20° 20° 18° 18° 18°

End Dish (Center Clearance) 3° 3° 2° 2° 2° 2° 2° 2° 1° 1° 1° 1° 1° 1° 1° 1° 1°

Machining Hard or Tough Materials These Angles can be Decreased by 20 percent

Cuttermaster Professional End Mill Resharpening Guide

General Purpose End Mill Recomended Angles

Performance Grind - High Speed Machining - Increase Angles by 20 Percent

Loading...

Loading...