www.cuttermasters.com - Toll Free (800) 417 2171

CUTTERMASTER Professional CM-01P User’s Manual

Page 19

3.2 End Mill End Grinding with an 11V9 Wheel.

Primary and Secondary Clearance angles

The tool rest is not needed for this operation as the spindle collars are tightend to completely restrict

the stroke of the spindle. Shorten the working end of the tool spindle as much as possible to reduce

deectionofthetoolspindlewhengrinding.Setthefrontcollarandtightenthetoolspindlesetscrew.

Bring the index collar up against the back of the spindle as shown in Figure 8, leaving just enough

gap so that the spindle can still rotate.

SettheCollarfora2,3,4,or6utes,dependingonthetoolbeingground.Engagetheindexpinand

tighten the collar set screw.

Puttheendmillinthecorrect5Ccolletforthetoolsizeandsettheutesperfectlyhorizontaland

tighten the collet using the collet draw tube at the end of the air spindle tube.

Set the motor angle at the desired angle for the grind, either primary or secondary. You may refer to

the angle chart on the front of the machine as a guide [Figure 6].

Raise or lower the motor so the center and edge of the wheel is in line with the tool rest. This is im-

portant to get the desired angle.

Feed across the tool to the center using the Y axis feed. Do not pass center. Retract the index pin

androtatethespindletubetotheotherutethenrepeattheprocessforboththeprimaryandsecond-

arygrind.Besuretomakealightnishpassontheprimaryof.0005orso.

Onceyou’resatisedthatthegrindsareasdesired,repeattheprocessforbothprimaryandsecon-

daNote: you will have to change the motor elevation when setting up to grind primary and secondary

angles in order to keep the center of the wheel at the correct height for grinding.

An alternate set up for ends uses a 1A1 wheel [Figure 9]. Using the outside face of the wheel, the

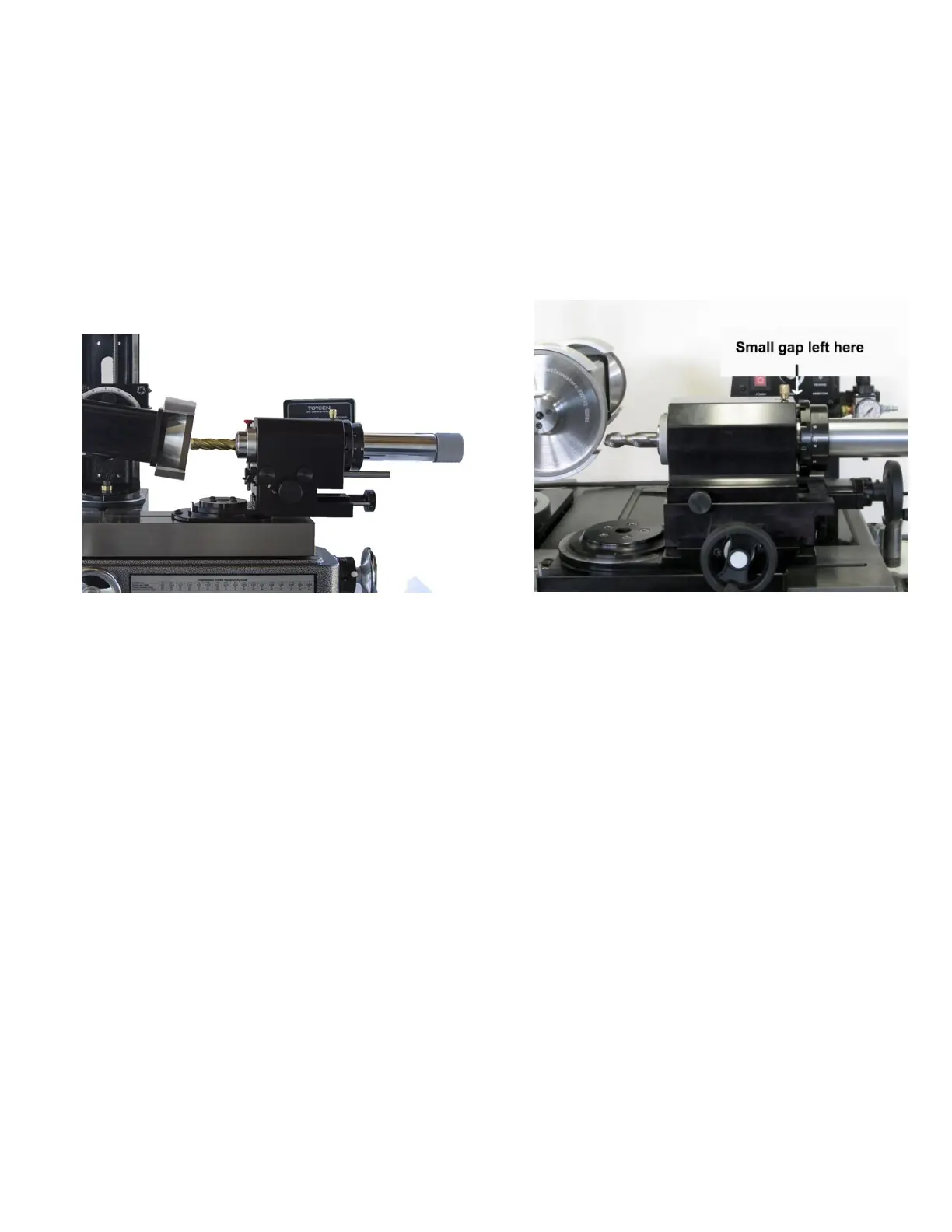

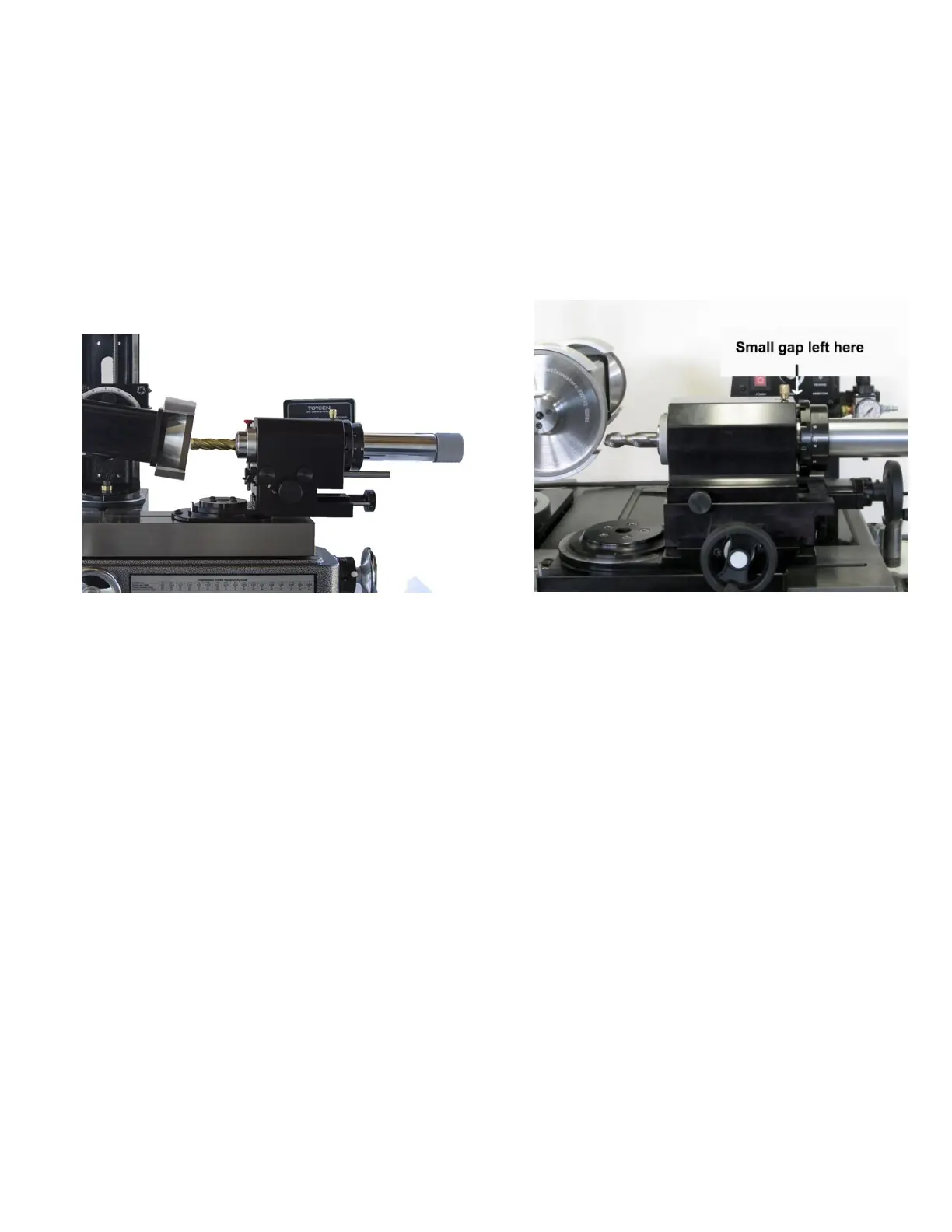

Figure 8. Set up for End Grinding

End Face Face Approach

Figure 9. End Mill End Grinding with 1A1

Wheel.

Loading...

Loading...