www.cuttermasters.com - Toll Free (800) 417 2171

CUTTERMASTER Professional CM-01P User’s Manual

Page 25

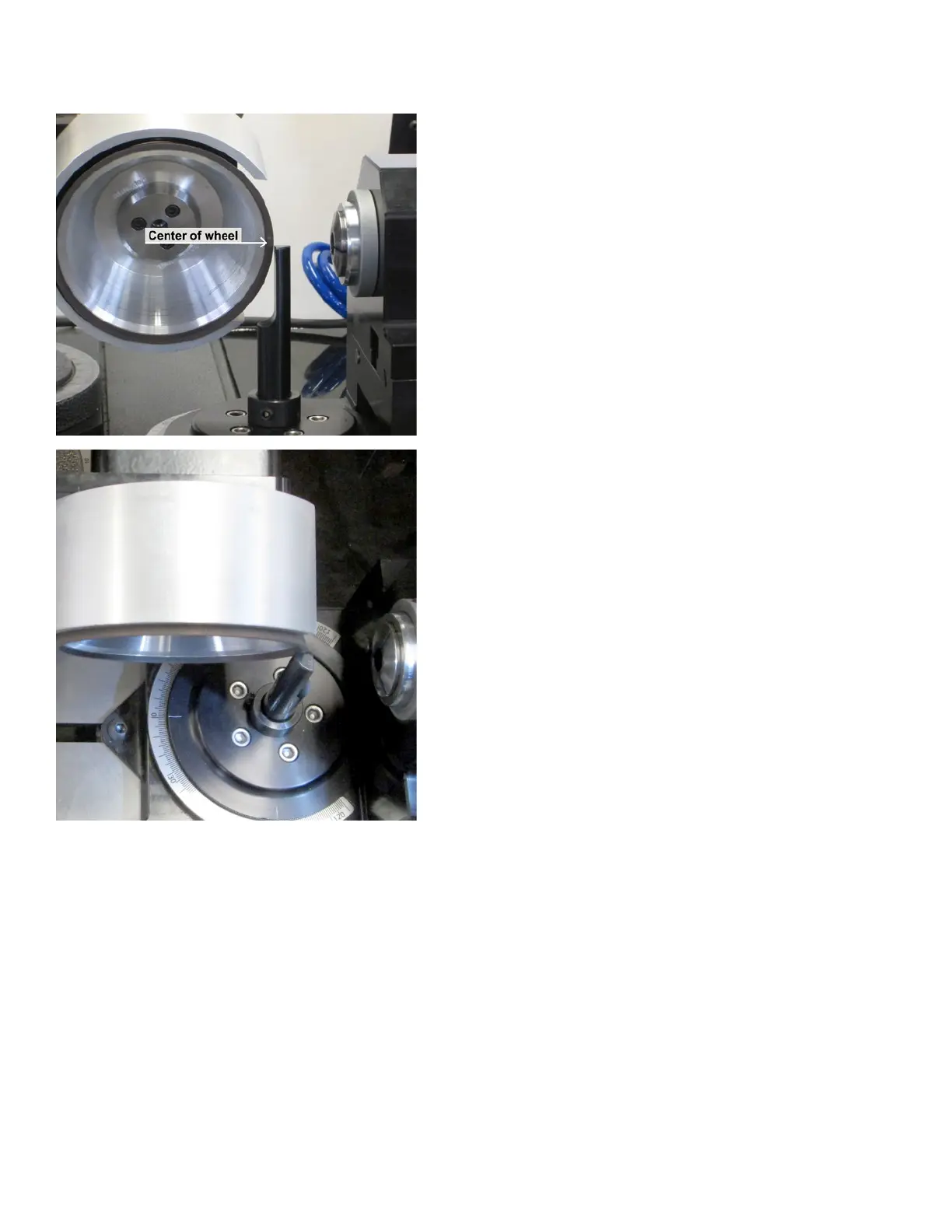

Locate Centers and Wheel Height

Installthecenternderintothereceiverinthecenterof

the radius assembly. Bring the grinding wheel close to

thecenternderandusethezaxisleadscrewtoset

the height of the wheel. The height of the wheel should

belevelwiththetopofthecenternder(centerofthe

tool).

Bring the wheel in to the pivot center at the correct

height and angle.

Wheel has to be at chosen angle and height to begin

the center location process.

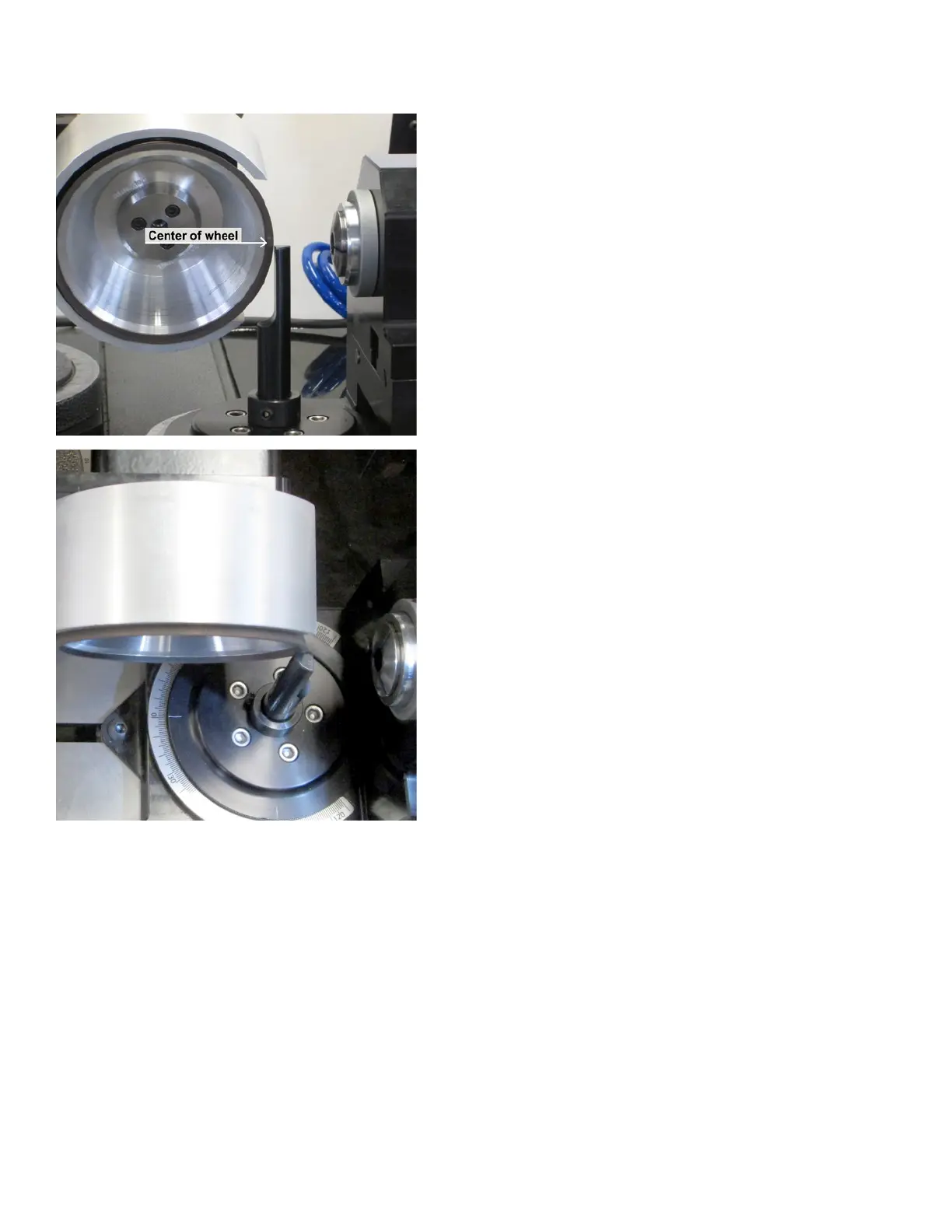

With the motor off, bring the wheel to the top corner of

thecenternderinbothaxesbyfeedingwiththelower

table feeds. Set your indicators to zerov.

Move the wheel away 0.200” in the y axis to remove the

centernderandreturntheyaxistabletozerousing

your indicator.

Themanualcenternderwillgetyouclosetothecen-

ter of the swing. Minor adjustments should be made if

additional accuracy is needed.

Load the tool.

Move the air spindle upper y axis carriage away from the wheel to load the tool. You don’t want to

move the lower table x or y feed screws after they have been positioned. Clamp the collet on the

shankoftheendmillandnottheutesifpossible.Theendmillutesshouldbelevelwiththetable,

ortippedslightlydowndependingonthetoolhelixSettheindexingcollartotherequireduteposi-

tion.

Set the wheel position for your desired radius.

For this example we will set up for a .150” radius. The grinding point of your wheel has previously

been located at center and your y axis indicator has been set to zero.

Note: We are using dial indicators to keep track of table

movements. e graduated dials can be used if you are

comfortable with that.

Loading...

Loading...