ENGLISH

18

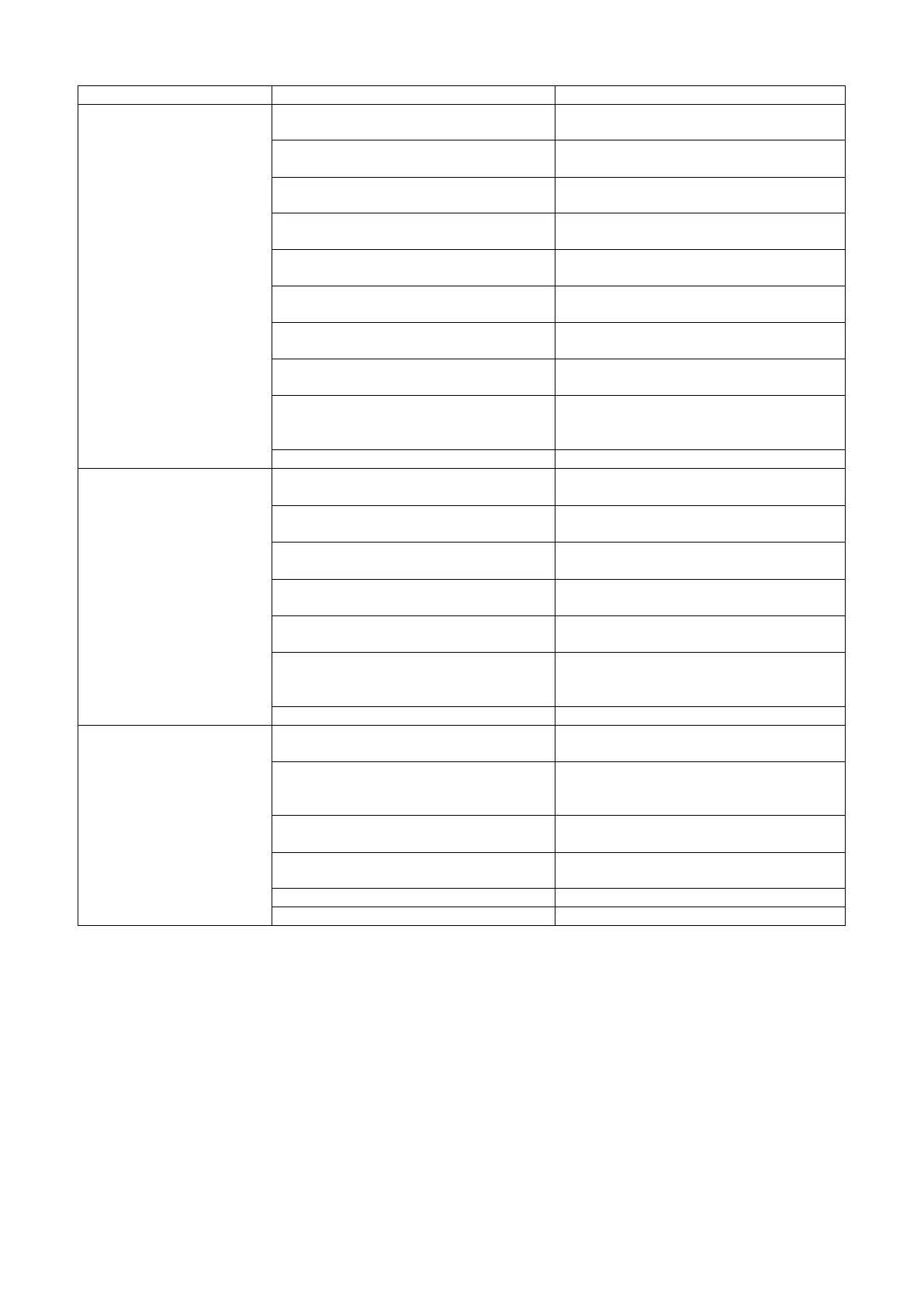

Electric pump starting with

thermal protection intervention

1. Power voltage differs from that stated on ID

plate.

1. Check motor input voltage. If necessary

contact electricity provider.

2. Three-phase motor. Phase interruption.

2. Restore motor power connections, then check

for proper current absorption.

3. Three-phase motor. Relay calibrated at too

low a value.

3. Adjust relay calibration, set it to a value slightly

higher than that shown on the motor ID plate.

4. Thermal overload relay faulty

4. Replace the faulty relay, check the system is

working properly.

5. Remove obstruction, wash and clean: if

necessary contact the DAB Assistance Service.

6. Incorrect direction of rotation

6. Reverse direction of rotation (see 7.2:

“Direction of Rotation”)

7. Pumped liquid too dense.

7. Dilute the liquid. Check the pumped liquid is

suitable (see “Technical Characteristics”).

8. Electrical pump dry-running.

8. Check the level of liquid in the tank and the

level control instruments.

9. Operation point outside working range.

9. Check electric pump operation point, check

delivery pipe characteristics and components. If

necessary contact the DAB Assistance Service.

10. Electric pump not working.

10. Contact the DAB Assistance Service.

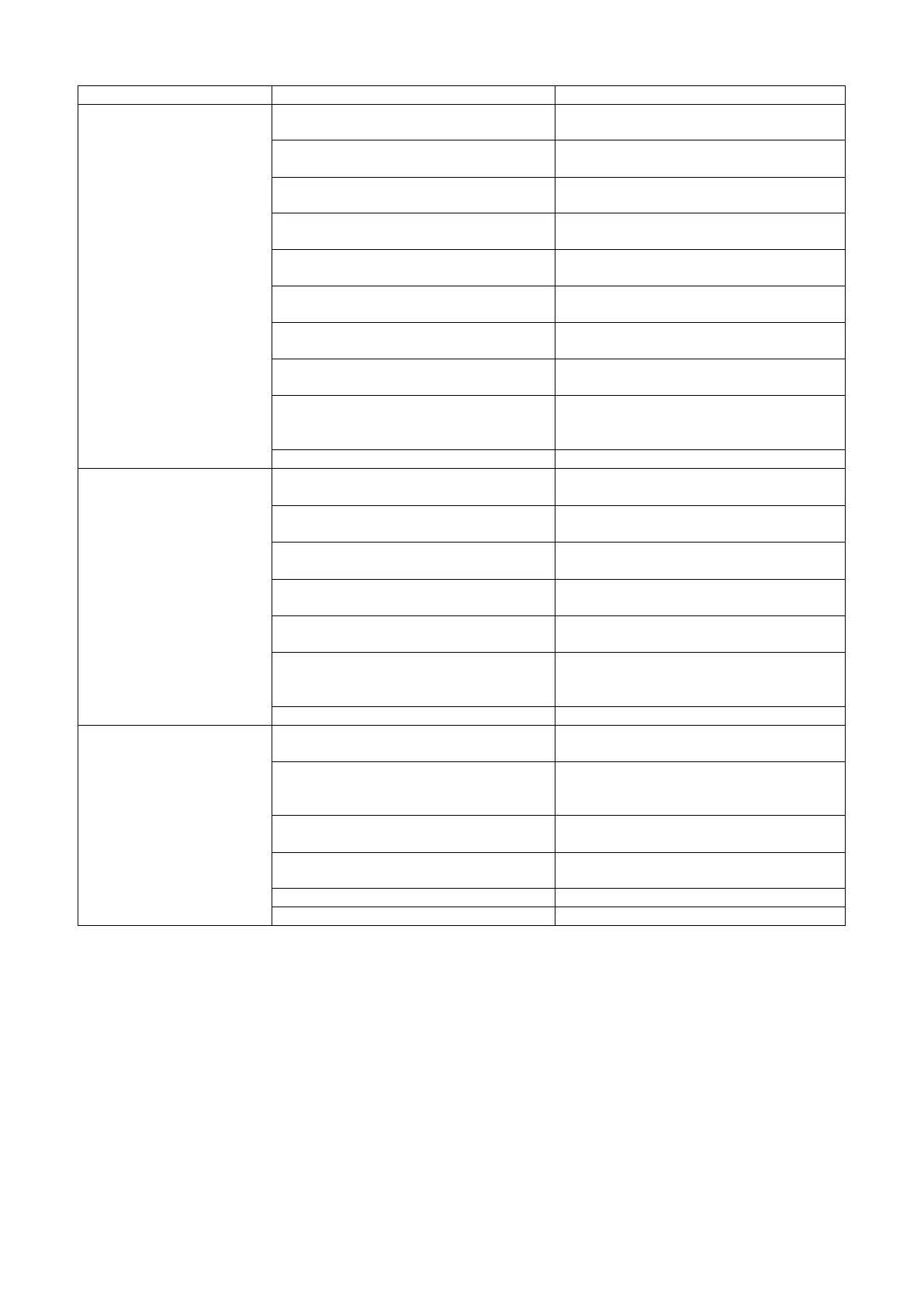

Electric pump drawing more

power than value shown on ID

plate.

1. Power voltage differs from that stated on ID

plate.

1. Check motor input voltage. If necessary

contact electricity provider.

2. Three-phase motor. Phase interruption.

2. Restore motor power connections, then check

for proper current absorption.

3. Incorrect sense of rotation.

3. Reverse direction of rotation (see 7.2:

“Direction of Rotation”)

4. Remove obstruction, wash and clean: if

necessary contact the DAB Assistance Service.

5. Pumped liquid too dense.

5. Dilute the liquid. Check the pumped liquid is

suitable (see “Technical Characteristics”).

6. Operation point outside working range.

6. Check electric pump operation point, check

delivery pipe characteristics and components. If

necessary contact the DAB Assistance Service.

7. Electric pump not working.

7. Contact the DAB Assistance Service.

Performance too low, the pump

does not perform as required.

1. Incorrect direction of rotation

1. Reverse direction of rotation (see 7.2:

“Direction of Rotation””)

2. Operation point outside working range.

2. Check electric pump operation point, check

delivery pipe characteristics and components. If

necessary contact the DAB Assistance Service.

3. Liquid pumped with air or gas present.

3. Increase collection tank size. Install de-

gassing devices.

4. Pumped liquid too dense.

4. Dilute the liquid. Check the pumped liquid is

suitable (see “Technical Characteristics”).

5. Pump not primed, air inside pumping body

5. Check pump priming (see “priming plug”)

6. Electric pump not working.

6. Contact the DAB Assistance Service.

Loading...

Loading...