D1146/D1146TI/DE08TIS

MAINTENANCE MANUAL

140

Printed in Jan. 2001 PS-MMA0415-E1A

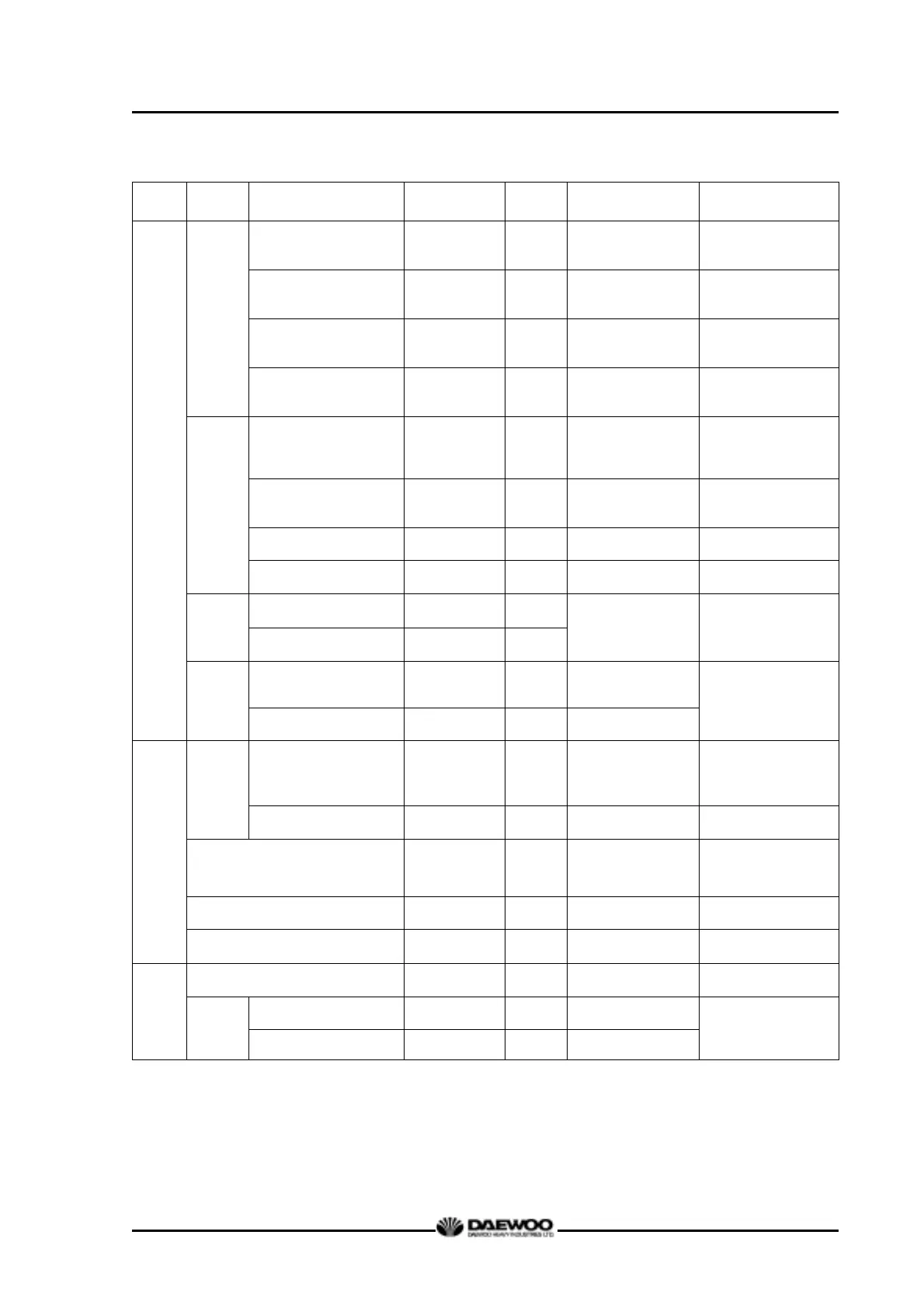

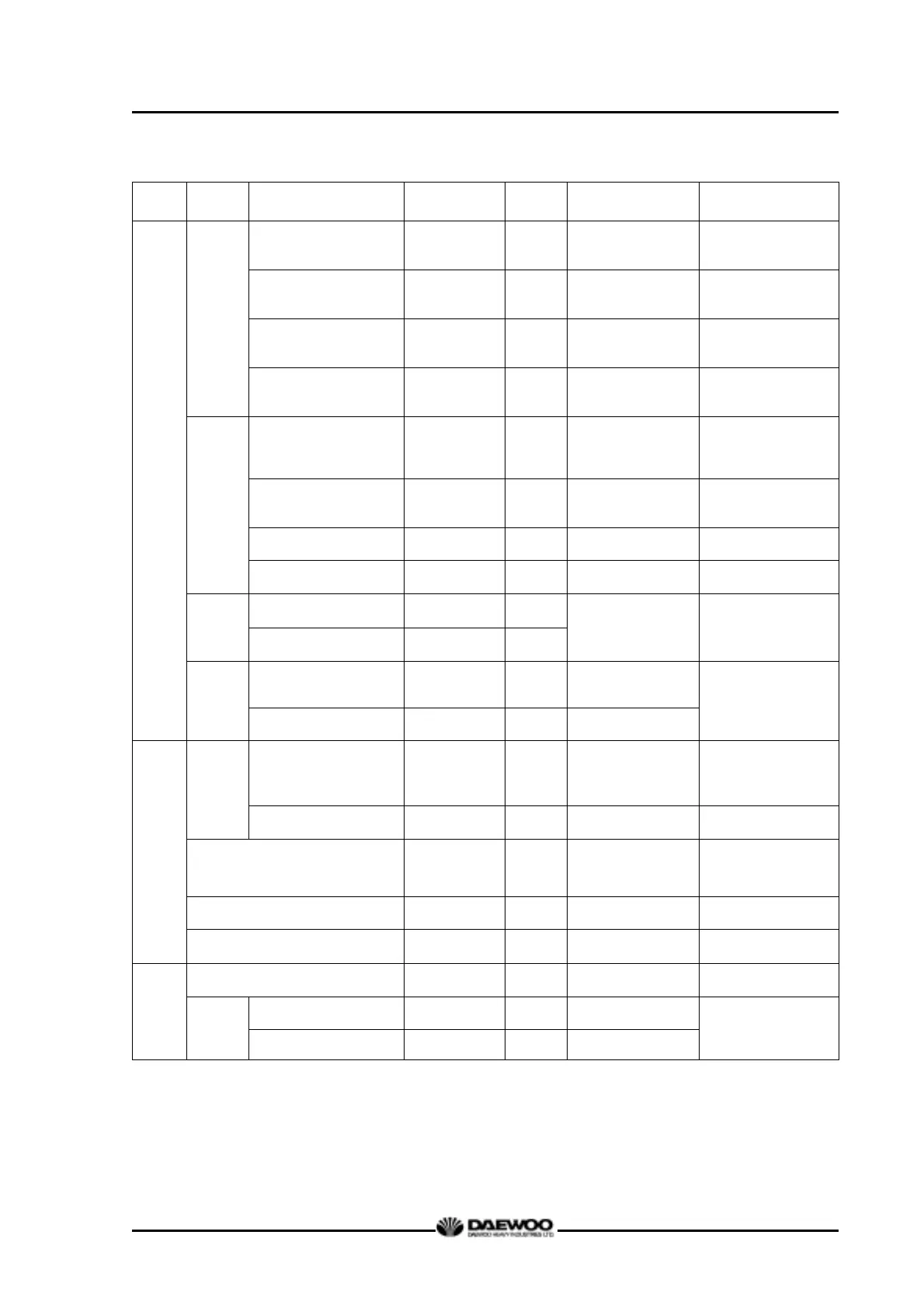

Group Part Inspection Item

Stand value

for assembly

Limit

For use

Correction Remark

Radiator & water pump

for corrosion, damage &

improper connecting

- - Correct or replace

Test for leakage

(air pressure) (kg/cm

2

)

1.0 -

Submerge in water

and replace if air

bubbles found

Pressure valve for

opening pressure

(kg/cm

2

)

0.5 -

Radiator

Negative pressure valve

for opening pressure

(mmHg

)

20 -

Delivery volume l/min

- Engine speed 2,700rpm

- Water temp. 80°C

- Pressure : 0.8

kg/cm

2

280 -

Check the water

passage

For any restrictions

Clearance between

impeller & housing

0.35 -

Replace if impeller

& housing are

damaged

Perpendicularity of

pulley

0.3

Adjust by a bench

press

Water

pump

Fan belt depression(with

thumb) mm

Approx. 15 - Adjust

Operating temperature

(permissible temp.) °C

79~95 -

Cooling

water

temp

Permissible temperature

in a short time °C

- 105

Must not exceed this

value

Thermostat

opening temp. °C

(under atmospheric pressure)

79 - Replace

Cooling

system

Thermostat

Full opening temp. °C

94 -

Replace if defective

Stroke : min. 8mm

Type –II

- Opening temp. : 83°C

- Full opening temp.:

95°C

Fuel pipe, injection pipe

& nozzle holder for

damage, cracks,

improper packing, etc.

- - Repair or replace

Piping

&

others

Fuel filter cartridge for

damage or dimple

- - Replace cartridge

Injection pressure of injection

nozzle (kg/cm

2

)

1146 : 210

1146TI : 214

E08TIS: 1st 160

2nd 220

- Adjust by shim

Operating pressure of overflow

valve (kg/cm

2

)

1.0~1.5 - Replace valve

Fuel

system

Projection height of nozzle from

the cyl. head surface(mm)

2.53 - Replace seal ring

Running-in the engine - -

Refer to supplement

“running-in”

Compression pressure of

cylinder (kg/c

2

)

24 ~ 28

24 or

more

Correct

nspection

at

completion

Cylinder

pressure

Compression pressure

difference of each cylinder

±10% or less

against average

Correct

at 200rpm or more

(20°C)

Loading...

Loading...