D1146/D1146TI/DE08TIS

MAINTENANCE MANUAL

59

Printed in Jan. 2001 PS-MMA0415-E1A

0.05 mm 0.2 mm

3.2.5. Crankshaft

(1) Inspection of crankshaft

1) Defect check

z By naked eyes, check for any

scratch or damage on the

crankshaft journal and crank pin.

z By means of magnetic particle test

and color check, check the

crankshaft for any crack and if

found, replace it.

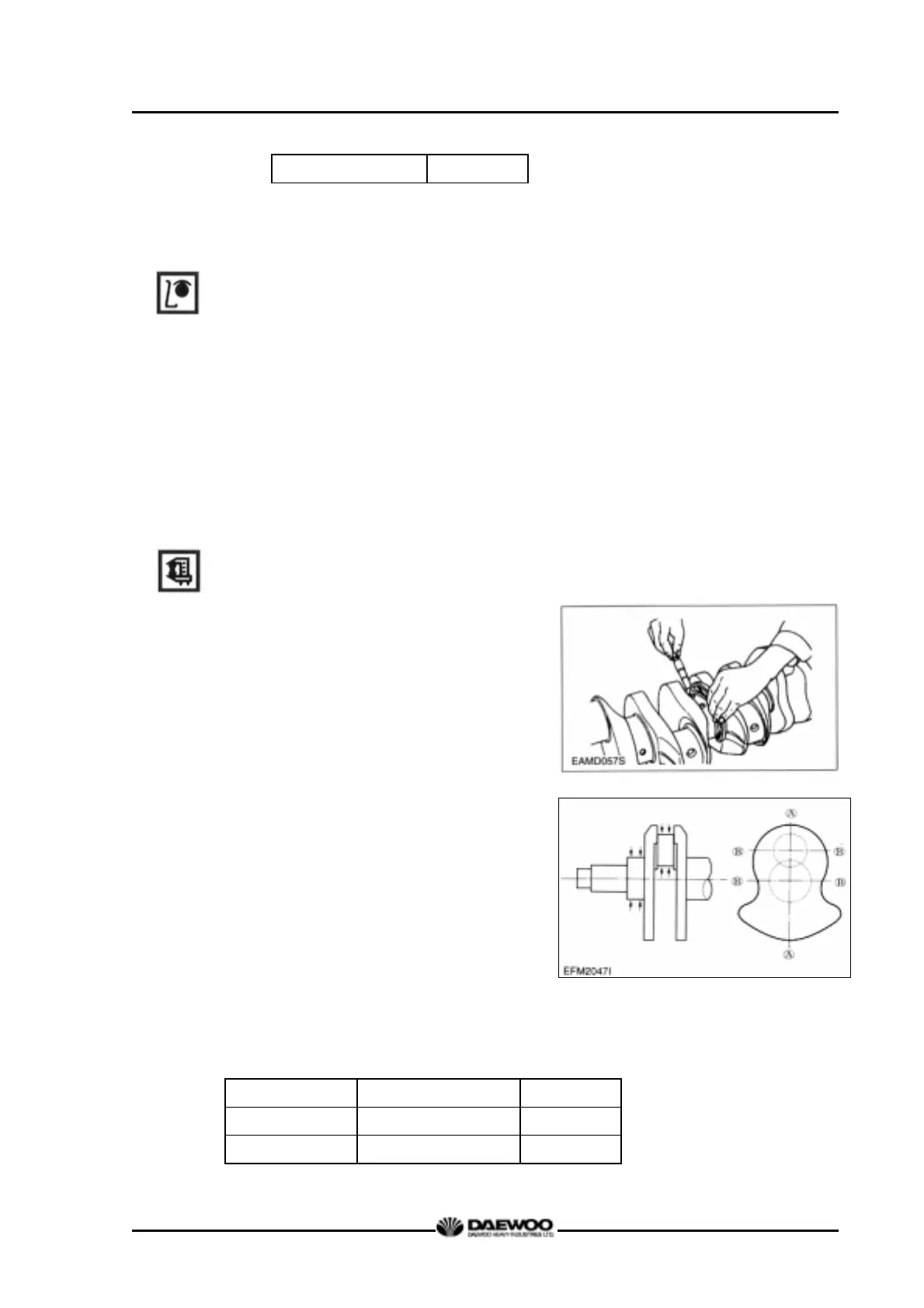

2) Wear measuring

z With an outside micrometer measure

the diameter of the crankshaft journals

and pins in the directions as shown,

and compare the measured values to

determine the amount of wear.

z If the amount of wear is beyond the

limit, have the crankshaft ground and

install undersize bearings. However, if

the amount of wear is within the limit,

you can correct the wear using an oil

stone or oiled grinding paper of fine

grain size. (Be sure to use grinding

paper which has been immersed in

oil.)

Standard

Limit

Journal diameter

φ83.966 ∼ φ83.988 mm φ83.000 mm

Pin diameter

φ70.971 ∼ φ70.990 mm φ70.000 mm

Loading...

Loading...