8 | Piping installation

Installer reference guide

65

ERLA03DAV3 + EHFZ03S18DJ3V

Daikin Altherma 3 R F

4P596821-1B – 2021.10

▪ Piping connections: Only flare and brazed connections are allowed. The indoor

and outdoor units have flare connections. Connect both ends without brazing. If

brazing should be needed, take the guidelines in the installer reference guide

into account.

▪ Flare connections: Only use annealed material.

▪ Piping diameter:

Liquid piping Ø6.4mm (1/4")

Gas piping Ø9.5mm (3/8")

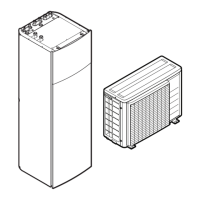

▪ Piping temper grade and thickness:

Outer diameter (Ø) Temper grade Thickness (t)

(a)

6.4mm (1/4") Annealed (O) ≥0.8mm

9.5mm (3/8") Annealed (O) ≥1.0mm

(a)

Depending on the applicable legislation and the maximum working pressure of the unit

(see "PS High" on the unit name plate), larger piping thickness might be required.

8.1.2 Refrigerant piping insulation

▪ Use polyethylene foam as insulation material:

- with a heat transfer rate between 0.041 and 0.052 W/mK (0.035 and

0.045kcal/mh°C)

- with a heat resistance of at least 120°C

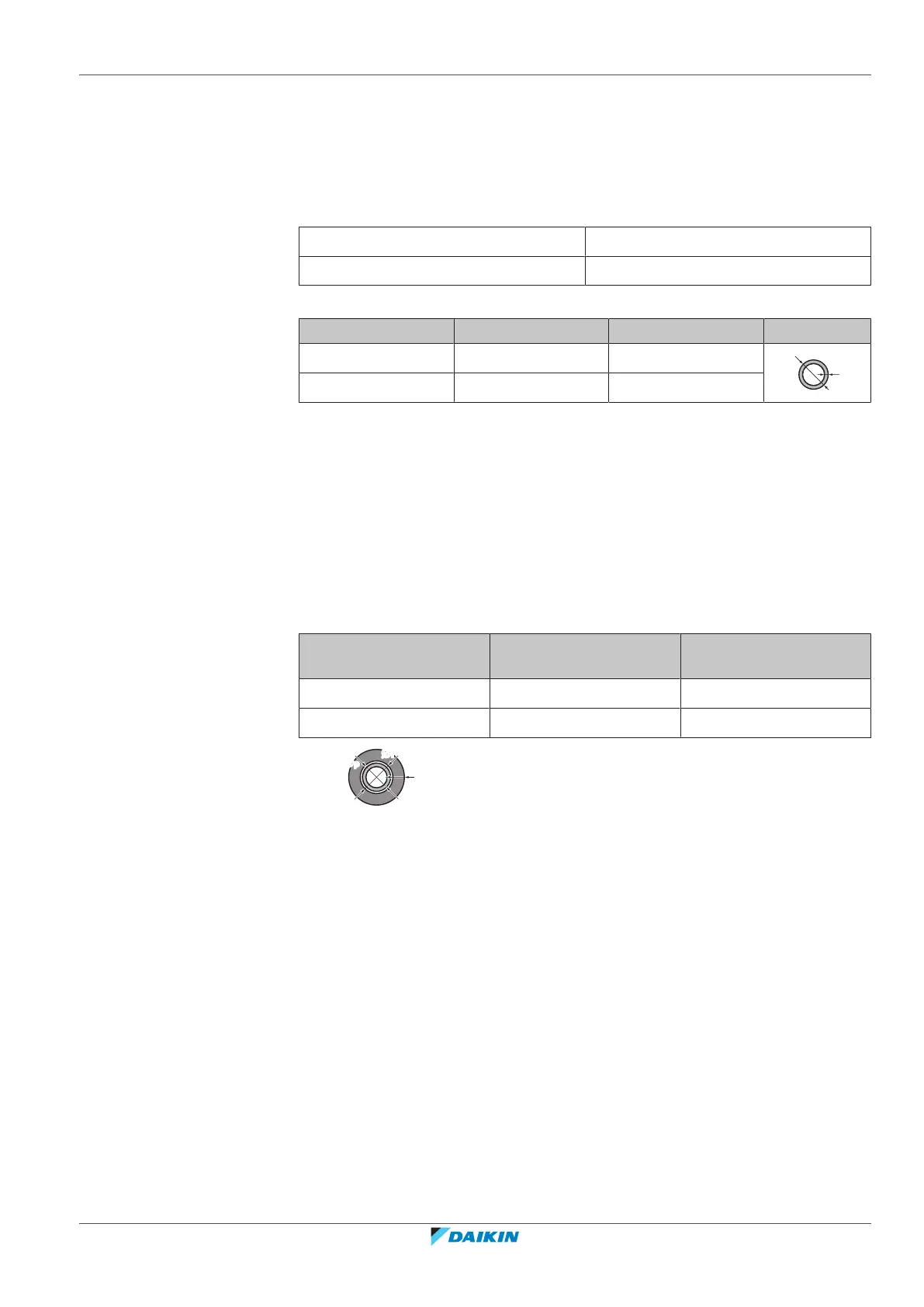

▪ Insulation thickness

Pipe outer diameter (Ø

p

) Insulation inner diameter

(Ø

i

)

Insulation thickness (t)

6.4mm (1/4") 8~10mm ≥10mm

9.5mm (3/8") 10~14mm ≥13mm

If the temperature is higher than 30°C and the humidity is higher than RH80%, the

thickness of the insulation materials should be at least 20 mm to prevent

condensation on the surface of the insulation.

8.2 Connecting the refrigerant piping

8.2.1 About connecting the refrigerant piping

Before connecting the refrigerant piping

Make sure the outdoor and indoor unit are mounted.

Typical workflow

Connecting the refrigerant piping involves:

▪ Connecting the refrigerant piping to the outdoor unit

▪ Connecting the refrigerant piping to the indoor unit

▪ Insulating the refrigerant piping

Loading...

Loading...