4 www.daikincomfort.com IO-DPV

Installaon

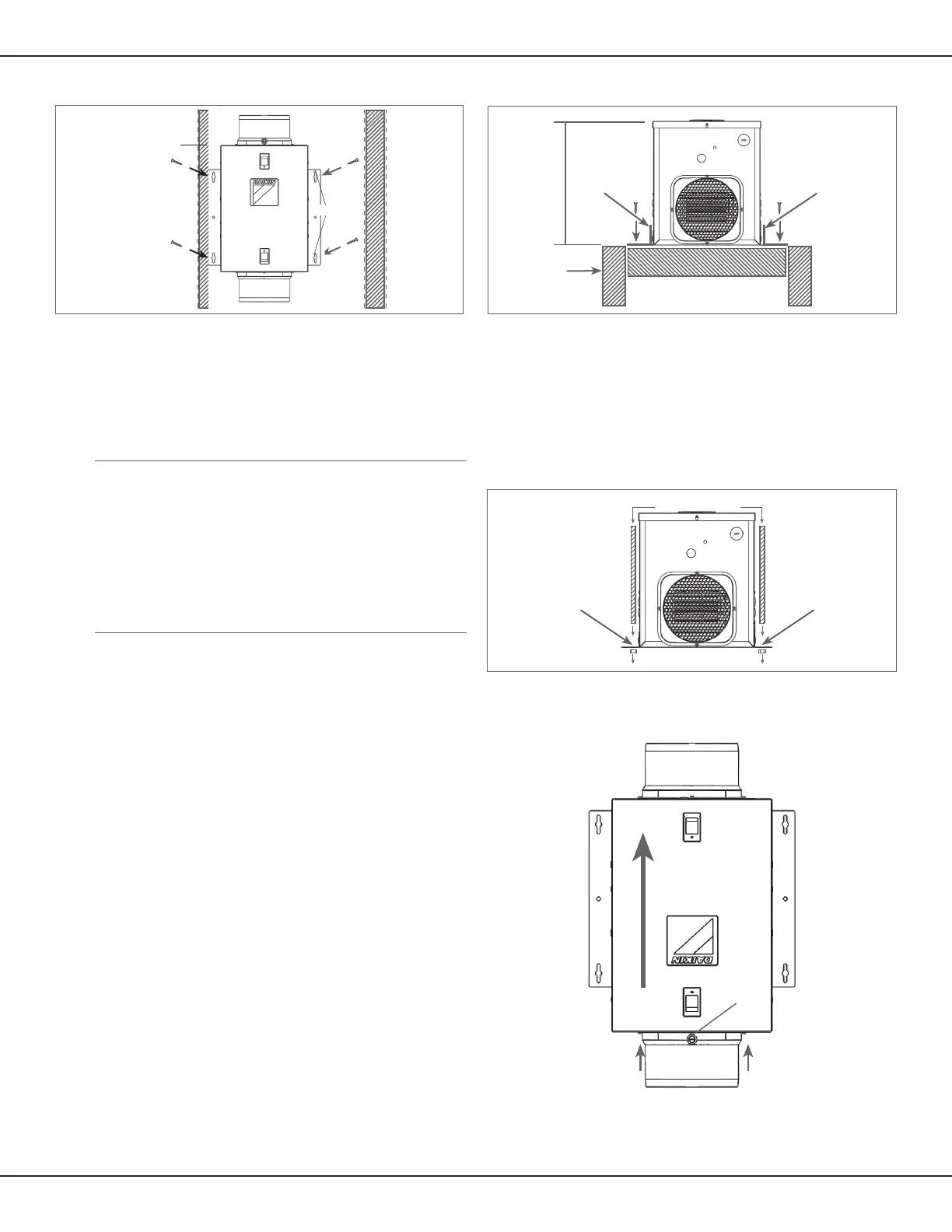

Screws

Air Flow

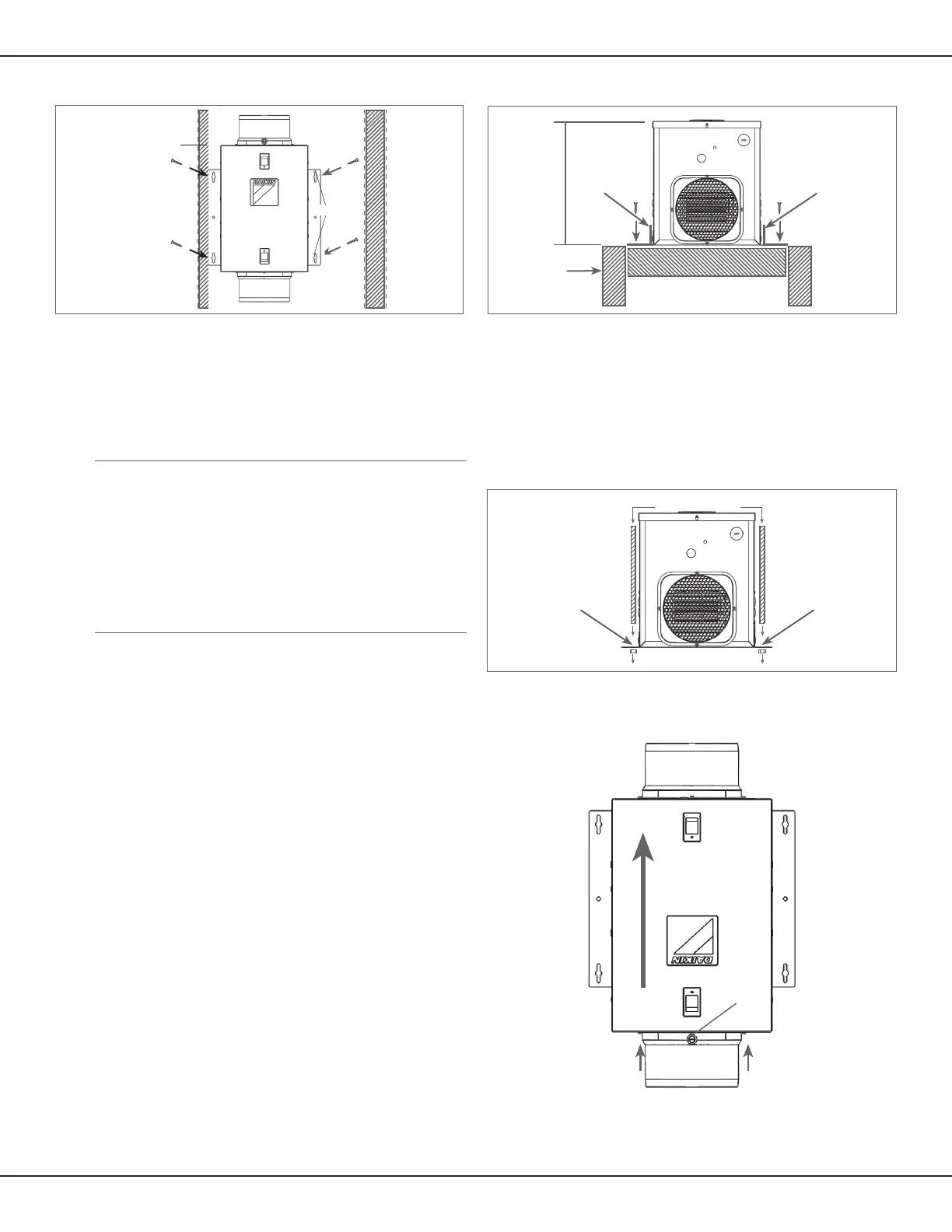

Figure 2 - Mounng venlator to a joist

Joist

2 x 4 Header

Bracket

BracketBracket

Bracket

11½"

Ducng the Venlator

NOTE: 6" diameter or larger rigid duct is recommended for

best performance.

CAUTION!

All ducng must comply with local and naonal building codes.

CAUTION!

The ducng from this venlator to the outside of the building

has a signicant eect on the airow, noise and energy

consumpon of the venlator. Use the shortest, straightest

duct roung possible between the venlator and the home’s

exterior for best performance, and avoid installing the

venlator with smaller diameter ducts than recommended.

Insulaon around the ducts can reduce energy loss and help

inhibit mold growth. Venlators installed with exisng ducts

may not achieve their rated airow.

CAUTION

Make sure the outdoor air intake port complies with all local

and naonal codes and is located at least 6 feet away from

sources of contaminaon such as but not limited to: clothes

dryer exhaust, furnace or central vacuum exhausts, gas appli-

ances such as BBQ grills, garbage bins or other exhaust ports.

Note: To ensure quiet operaon of this venlator, the

ducng

shall be installed using sound aenuaon techniques

appropriate for the installaon. For bathroom and general

venlaon applicaons, at least 8 feet of insulated exible

duct shall be installed between the exhaust or supply grille(s)

and the venlator.

1. Connect ducng to the venlator’s intake and outlet duct

collars (Figure 4), sealing the joints with appropriately

rated tape. Use screws or suitable clamps to secure in

place. Make sure the outdoor air intake is connected to

an intake port ed with a suitable Air Intake Hood with

insect screen to protect air intake. It is recommended that

low restricon terminaon ngs be used.

2. To reduce the potenal for condensaon buildup within

the duct, seal duct joints and exterior penetraons with

masc, caulk or other appropriate material to create an

air-ght path to and from the venlator.

3. To reduce the potenal for building heat loss or gain and to

reduce the potenal for condensaon, wrap insulaon

around duct and/or venlator.

i

i

i

NOTE: At the base of the intake duct collar, there is a small test port

hole covered with a red plasc cap. Make sure the test port is not

covered up by the ducng or insulaon and can be accessed for

owrate measurement. To access the port, remove the red, plasc

port cover and insert pitot tube to measure owrate.

Figure 3 - Mounng venlator using hanging rods

Housing

Threaded Rod

Figure 4 - Connecng ducng to the venlator

Figure 1 - Surface mounng of venlator

Intake

Ducng

Test Port

Outlet

Ducng

Air Flow

Stud/Joist

Anchors

Loading...

Loading...