Si39-303

iv Drawings & Flow Charts

E

Electrical Work

a PCB for remote control, multiple core cable

must not be used .................................53

Choosing a circuit breaker................................53

Earthing ............................................................54

When cable more than 1.25 mm² is used.........52

Example of Connection.........................................173

Excessive noise due to incorrect angling of

REFNET joints ...............................................148

F

Field line connection .............................................183

........................................................................186

Field Setting From Outdoor Unit

Mode changing procedure................................80

Field Wiring

RXYQ18~32MY1B..........................................142

RXYQ34~48MY1B..........................................143

RXYQ5~16MY1B............................................141

Flare Gauge ............................................................24

Flaring Procedure....................................................25

Flaring tool ............................................................226

Floor Standing/Concealed Floor Standing Type

(FXLQ-M, FXNQ-M).........................................52

Front Piping

BHFP22M135 .................................................121

BHFP22M90 ...................................................121

G

Gauge manifold for R410A....................................228

H

Hand Over to Customer

Important Points .............................................105

Make the service contact address clear .........105

Operational Steps...........................................105

How these installation problems affect

an equipment .....................................................9

How to select the refnet header ............................114

How to select the refnet joint.................................113

I

Indoor Unit Remote Controller ................................90

Inspecting and Handling the Unit ................... 58

,

164

Installation of Gas Side Pipes ...............................122

Installation of Indoor Unit

Ceiling mounted cassette type (FXCQ63M) .....16

Operational steps .............................................16

Positioning ........................................................16

Installation of liquid side pipes and oil pipe...........123

installation of multiple outdoor units......................171

Installation of Outdoor Unit

Bolt pitch...........................................................59

Operational steps .............................................59

Unpacking and Placing the Unit .......................60

interconnecting wiring ...........................................190

K

knocking out knock holes ......................................189

L

laying power wiring............................................... 185

Leak test............................................................... 175

Leak tester ........................................................... 228

M

Mismatch between cables connecting indoor and

outdoor units and corresponding piping ........ 145

Movement of the air flow flap ............................... 210

N

Names and functions of parts .............................. 202

O

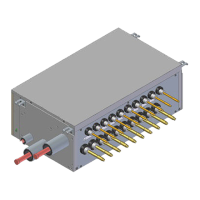

Outdoor Unit Multi Connection Piping Kit............. 119

Outdoor Unit PC Board Layout .............................. 66

P

Picking power line and transmission line.............. 188

Pipe Insulation...................................................... 177

Pipe size............................................................... 115

Piping Installation Point........................................ 108

Piping System Diagrams

Indoor Unit ..................................................... 137

RXYQ10MY1B............................................... 135

RXYQ12MY1B............................................... 135

RXYQ14MY1B............................................... 136

RXYQ16MY1B............................................... 136

RXYQ5MY1B................................................. 134

RXYQ8MY1B................................................. 135

Positioning of indoor unit.......................................... 8

Positioning of outdoor unit........................................ 8

Pressure down despite absence of leaks during air

tight test......................................................... 147

Procedure for Checking Dangerous

Concentration................................................ 102

Program Dry Operation ........................................ 209

Programming Start and Stop of the System

with Timer...................................................... 211

proper distances away from stereo equipment,

personal computers, etc.......................... 56

,

162

R

REFNET Header .................................................. 127

REFNET header................................................... 128

REFNET Joint ...................................................... 126

REFNET joint ....................................................... 128

Refrigerant Cylinders ........................................... 224

Refrigerant Leaks................................................. 194

Refrigerant oil (Air compal)................................... 228

Refrigerant Pipe Flushing

Fit blanking plugs............................................. 20

Flushing ........................................................... 20

Open the main valve on the nitrogen cylinder and

set the pressure regulator to

0.5MPa ............................................... 20

Set pressure regulator on nitrogen cylinder..... 20

Refrigerant Pipe Work

Air tight............................................................. 17

Clean ............................................................... 17

Dry ................................................................... 17

Loading...

Loading...