www.DaikinApplied.com 11 IOM 1274-3 • CENTRIFUGAL WATER CHILLERS

damage or water side damage to the chiller heat exchangers

due to improperly treated water.

during initial chiller installation/commissioning and maintained

on a continuous basis by water treatment professionals (see

Limited Product Warranty).

CAUTION

The improper use of detergents, chemicals, and additives

performance and potentially lead to repair costs not covered

by warranty. Any decision to use these products is at the

discretion of the owner/occupant/operator/user and as such

they assume full liability/responsibility for any damage that

may occur due to their use.

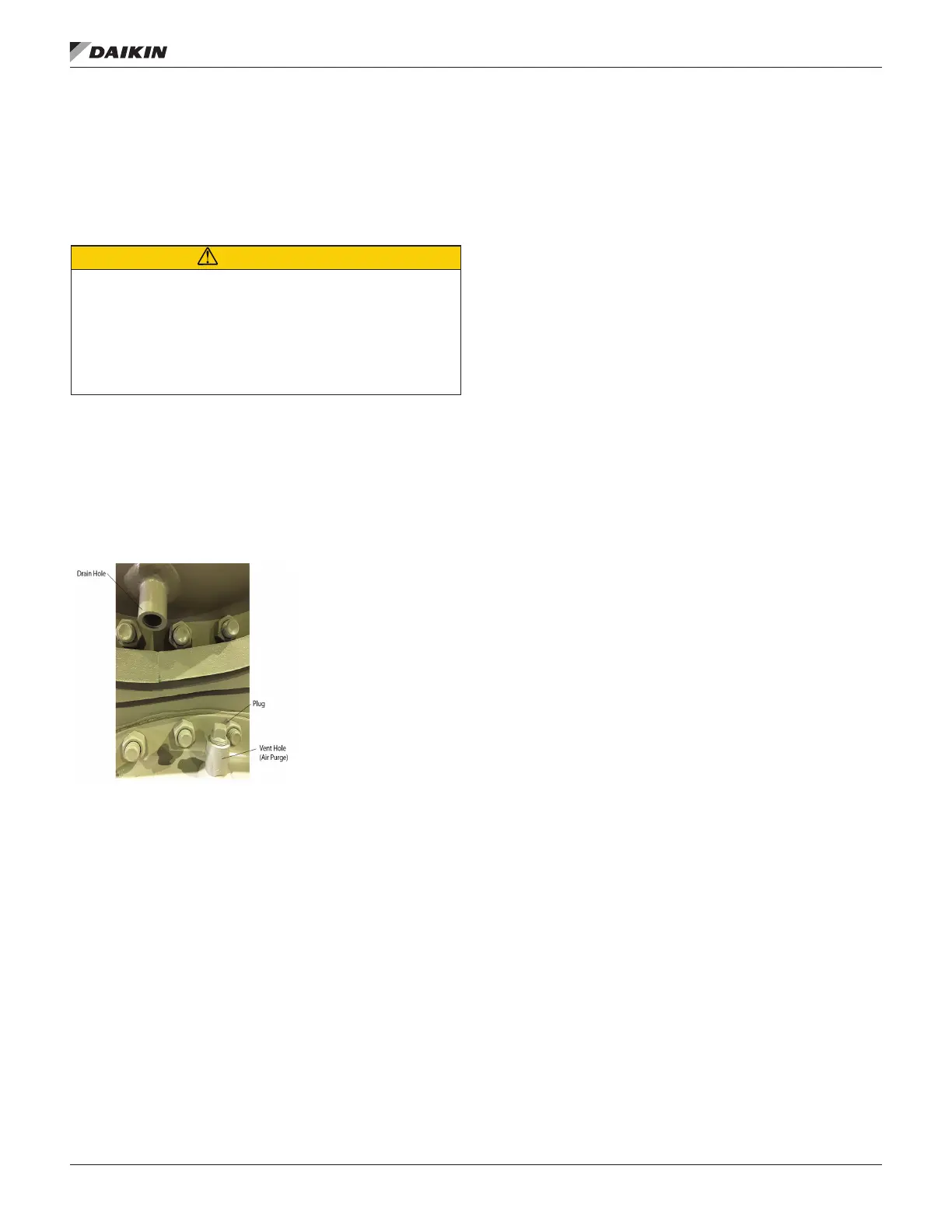

Vessel Drains at Startup

The unit is drained of water at the factory. Drain plugs for each

vessel head are shipped separately in the control box. Units

are shipped with the drain plug in the top water box drain hole

and no plug in the bottom drain hole. Install the bottom drain

Figure 4.

Figure 4: Drain Plug Installation

Flow Switches

wired. See the Field Wiring Diagram on page 32 or on the

cover of the control panel for proper connections. The purpose

until such time as both the evaporator water and condenser

started. See

69 for further information.

Variable Fluid Flow Rates

power, and potential tube erosion or corrosion damage.

be avoided as they will result in poor heat transfer, high

compressor power, sedimentation and tube fouling.

rate should not exceed 50% of the current value per minute.

should use 10% of the current value per minute as guidance.

All chilled water systems need adequate time to recognize a

load change, respond to that load change and stabilize, without

undesirable short cycling of the compressors or loss of control.

In air conditioning systems, the potential for short cycling

usually exists when the building load falls below the minimum

chiller plant capacity or on close-coupled systems with very

small water volumes.

Some of the things the designer should consider when looking

at water volume are the minimum cooling load, the minimum

chiller plant capacity during the low load period and the desired

cycle time for the compressors.

Assuming that there are no sudden load changes and that

the chiller plant has reasonable turndown, a rule of thumb of

“gallons of water volume equal to two to three times the chilled

A properly designed storage tank should be added if the

Operation of the chilled water pump can be to 1) cycle the

pump with the compressor, 2) operate continuously, or 3) start

automatically by a remote source.

The cooling tower pump must cycle with the machine. The

holding coil of the cooling tower pump motor starter must be

rated at 115 volts, 60 Hz, with a maximum volt-amperage rating

of 100. A control relay is required if the voltage-amperage

rating is exceeded. See “Figure 16: Centrifugal Field Wiring

or in the cover of control panel for

proper connections.

All interlock contacts must be rated for no less than 10

inductive amps. The alarm circuit provided in the control center

utilizes 115-volts AC. The alarm used must not draw more than

10 volt amperes.

Condenser Water Control

Condenser water control is an important consideration in chiller

plant design since condenser water temperature will directly

wet bulb temperature is lower than peak design, the entering

condenser water temperature from the cooling tower can

be allowed to fall, improving chiller performance. However,

operational issues may occur when the condenser water

temperatures are either too high or too low. The WSC chiller

Loading...

Loading...