IOM 1274-3 • CENTRIFUGAL WATER CHILLERS 14 www.DaikinApplied.com

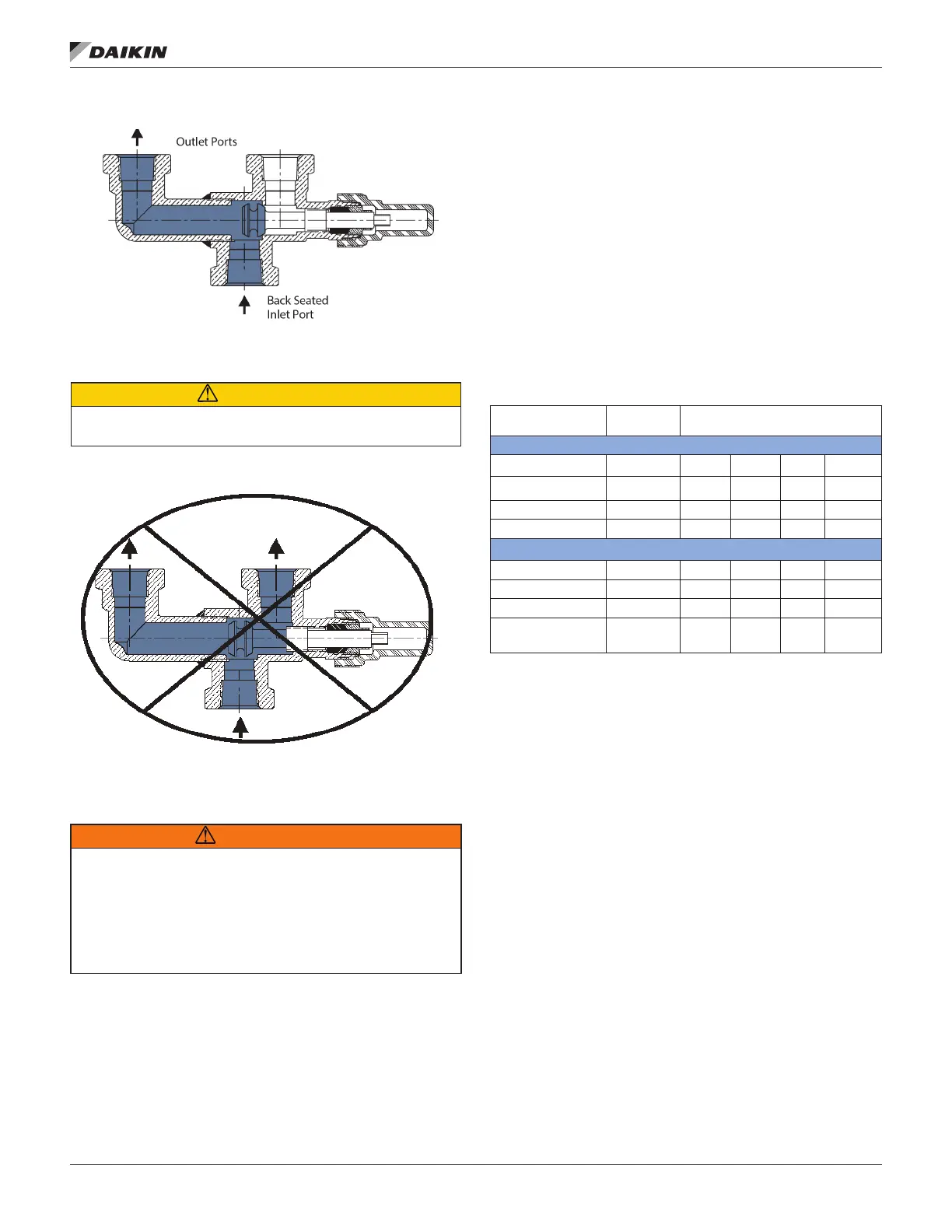

Figure 7: Three-Way Valve, Back Seated Position

When the valve stem is not pushed forward or pulled back

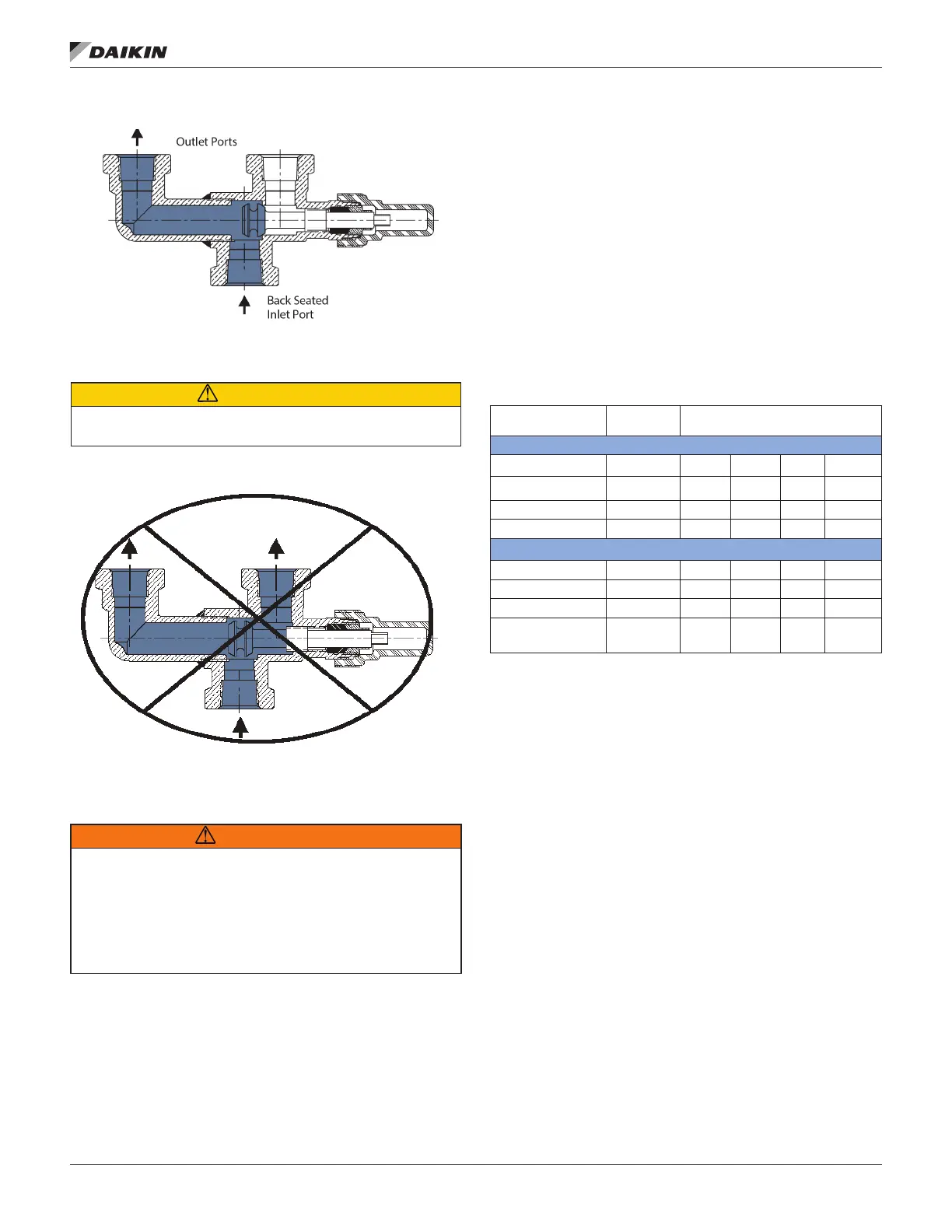

Figure 8.

CAUTION

Do not operate the system with the three-way valve stem in

the Mid Position.

Figure 8: Three-Way Valve, Mid Position

Oil Coolers

WARNING

This unit contains POE lubricants that must be handled

carefully and the proper protective equipment (gloves, eye

protection, etc.) must be used when handling POE lubricant.

Failure to do so can result in personal injury. POE must not

come into contact with any surface or material that might be

harmed by POE, including certain polymers (e.g. PVC/CPVC

and polycarbonate piping).

Daikin Applied centrifugal chillers (models 079-126) have

a factory-mounted, water-cooled oil cooler, temperature-

controlled water regulating valve and solenoid valve per

compressor. Centrifugal single compressor cooling water

connections are located near the compressor and are shown

Field water piping to the inlet and outlet connections must be

installed according to good piping practices and include stop

installed. The water supply for the oil cooler should be from

the chilled water circuit or from a clean, independent source,

no warmer than 80°F (27°C), such as city water. When using

chilled water, it is important that the water pressure drop across

the evaporator is greater than the pressure drop across the oil

drop across the evaporator is less than the oil cooler, the oil

cooler must be piped across the chilled water pump, provided

oil cooler will be adjusted by the unit’s regulating valve so that

the temperature of oil supplied to the compressor bearings

(leaving the oil cooler) is between 95°F and 105°F (35°C and

40°C).

Table 6: Oil Cooler Data

Compressors using chilled water for oil cooling will often start

loop temperature is pulled down. Data given above includes

that condition. As can be seen, with cooling water in the 45°F

to 65°F (7°C to 18°C) range, considerably less water will be

used, and the pressure drop will be greatly reduced.

When supplied with city water, the oil piping must discharge

through a trap into an open drain to prevent draining the cooler

by siphoning. The city water can also be used for cooling tower

makeup by discharging it into the tower sump from a point

above the highest possible water level.

NOTE: Particular attention must be paid to chillers with

In this case an auxiliary booster pump can be used or

city water employed.

Compressor

Model Size

Hot Side POE

Lube

Cold Side Water Options to achieve 100 °F

Outlet Temp

079 - 087 - Connection Size: 0.75 inches

Flow, gpm 9.9 11.9 2.9 2.0 1.54

Inlet Temp, °F 118.0 80.0 65.0 55.0 45.0

Outlet Temp, °F 100.0 87.3 94.5 98.3 101.4

Pressue Drop, psi - 4.3 0.3 0.14 0.09

100 - 126 - Connection Size: 1.0 inches

Flow, gpm 15.8 21.9 5.1 3.5 2.7

Inlet Temp, °F 120.0 80.0 65.0 55.0 45.0

Outlet Temp, °F 100.0 87.0 95.0 99.0 102.3

Pressue Drop,

psi

- 3.78 0.23 0.11 0.07

Loading...

Loading...