www.DaikinApplied.com 9 IOM 1274-3 • CENTRIFUGAL WATER CHILLERS

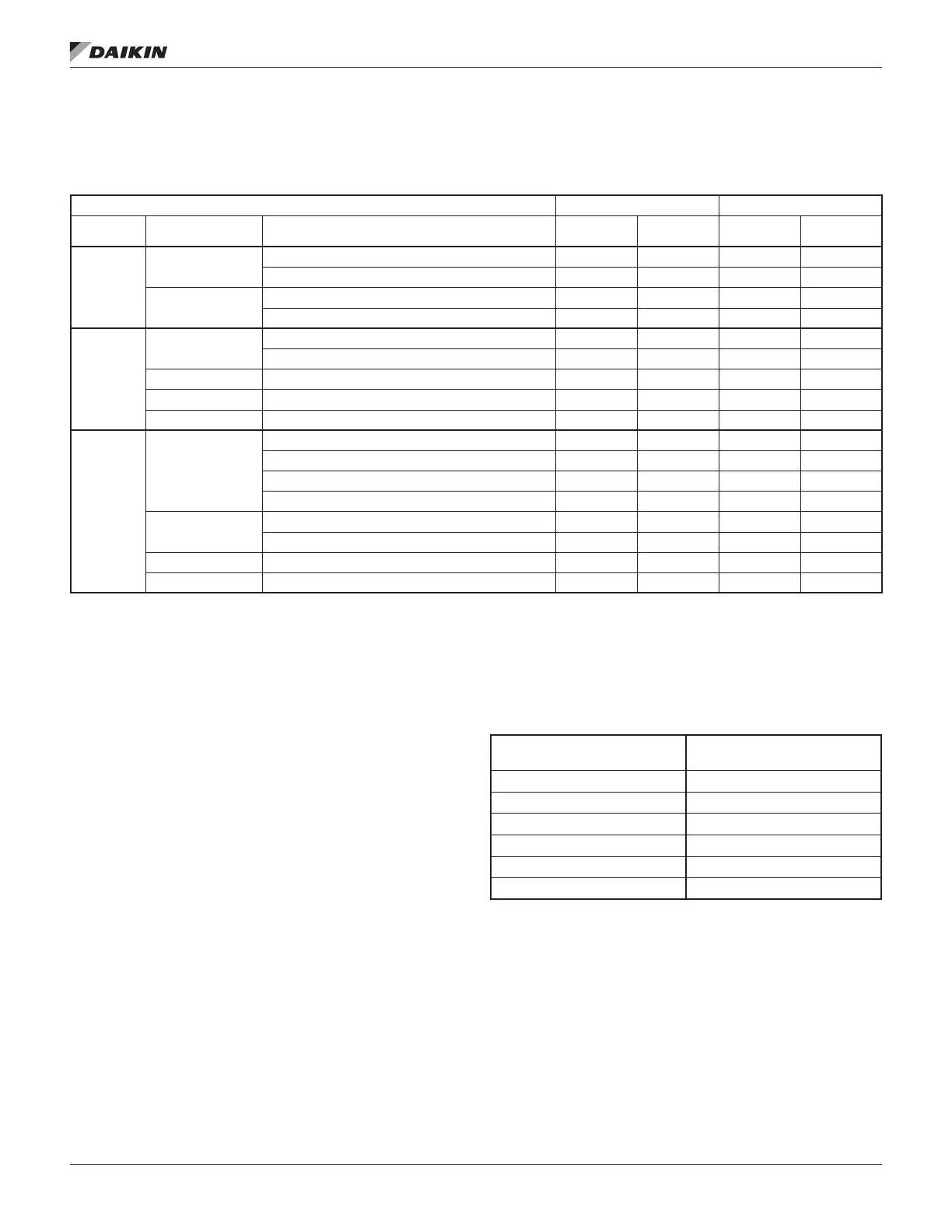

Table 2: Operating/Standby Limits

1

R-513A R-134a

Condition Description

°F (°C)

°F (°C)

°F (°C)

°F (°C)

Standby

Evaporator

Entering Fluid 35 (1.7) 86 (30) 35 (1.7) 90 (32.2)

Entering Fluid w/ Antifreeze

2

20 (-6.7) 86 (30) 20 (-6.7) 90 (32.2)

Equipment Room

Air w/ Water in Vessels & Oil Cooler 40 (4.4) 104 (40) 40 (4.4) 104 (40)

Air w/ no Water in Vessels & Oil Cooler 0 (-17.8) 0 (-17.8) 0 (-17.8) 113 (45)

Startup

Evaporator

Entering Fluid 38 (3.3) 100 (37.8) 38 (3.3) 100 (37.8)

Entering Fluid w/ Antifreeze

2

20 (-6.7) 100 (37.8) 20 (-6.7) 100 (37.8)

Condenser Entering Fluid 35 (1.7) 110 (43.3) 35 (1.7) 111 (43.9)

Oil Cooler Entering Fluid 35 (1.7) 80 (26.7) 35 (1.7) 80 (26.7)

Equipment Room Air 40 (4.4) 104 (40) 40 (4.4) 104 (40)

Operating

Evaporator

Entering Fluid 38 (3.3) 86 (30) 38 (3.3) 90 (32.2)

Leaving Fluid 38 (3.3) 60 (15.6) 38 (3.3) 60 (15.6)

Entering Fluid w/ Antifreeze

2

20 (-6.7) 86 (30) 20 (-6.7) 90 (32.2)

Leaving Fluid w/ Antifreeze

2

20 (-6.7) 60 (15.6) 20 (-6.7) 60 (15.6)

Condenser

Entering Fluid 55 (12.8) 104 (40) 55 (12.8) 105 (40.6)

Leaving Fluid See Note

3

110 (43.3) See Note

3

111 (43.9)

Oil Cooler Entering Fluid 35 (1.7) 80 (26.7) 35 (1.7) 80 (26.7)

Equipment Room Air 40 (4.4) 104 (40) 40 (4.4) 104 (40)

NOTES:

1

heat recovery mode limits)

2

Antifreeze temperature limits must have appropriate glycol concentration

3

Field Insulation

If the optional factory-installation of thermal evaporation

to reduce heat loss and prevent condensation from forming.

Insulation should cover:

• the evaporator barrel, tube sheet, and waterboxes.

• the suction line from the top of the evaporator to the

• the compressor support brackets welded to the

evaporator.

• the liquid line from the expansion valve to the evaporator

inlet, including the expansion valve.

• the part load balance valve to the evaporator.

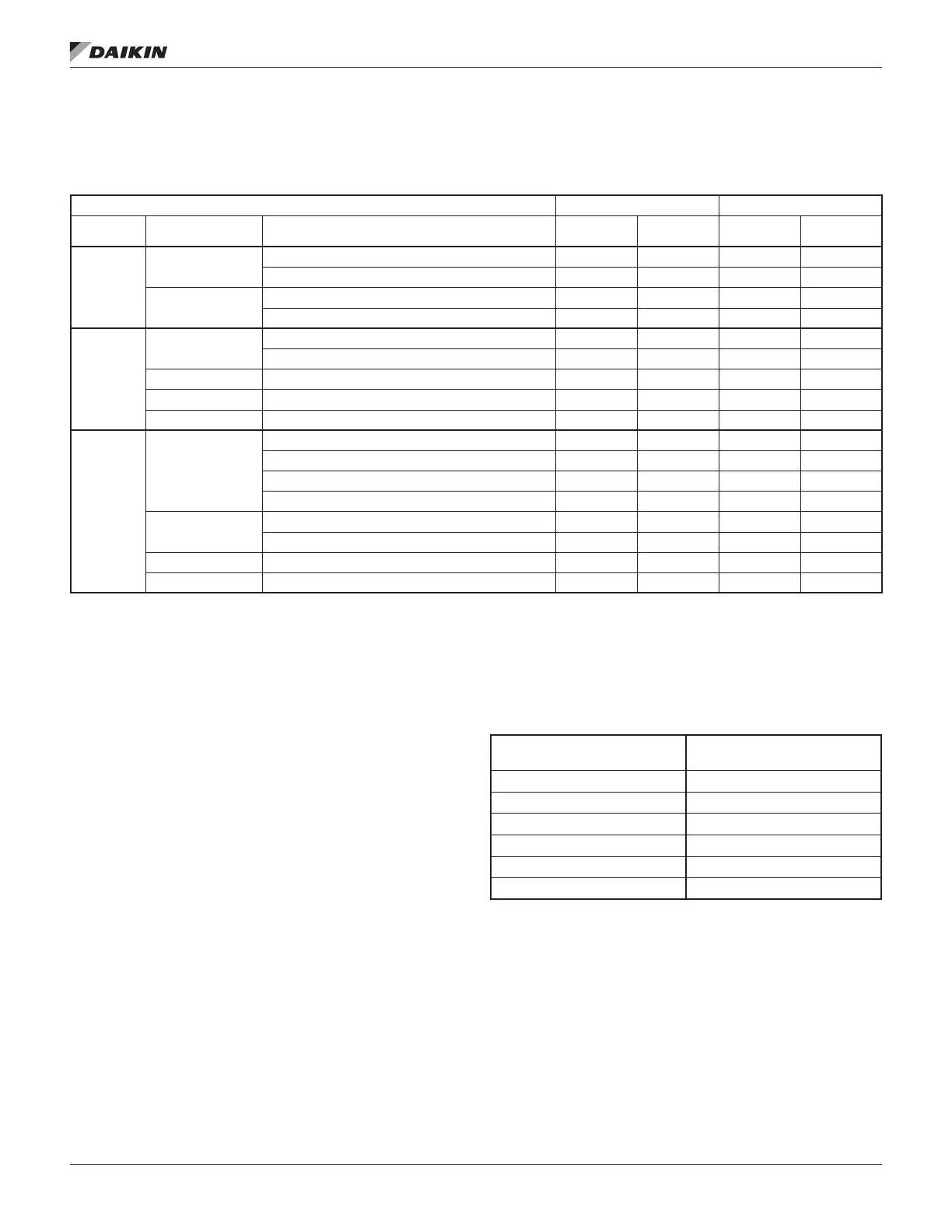

Approximate total square footage of insulation surface required

for individual packaged chillers is tabulated by code and can

be found in Table 4. Condenser references included for TSC

model units only.

Table 4: Insulation Area Required for Vessels

Vessel Code Insulation Area

E2612 / C2612 102 (9.4)

E3012 / C3012 115 (10.6)

E3612 / C3612 129 (11.9)

E4212 / C4212 148 (13.7)

E4216 / C4216 264 (24.5)

E4816 / C4816 302 (28.1)

Water Piping

All evaporators and condensers have OGS-type grooved water

connections (adhering to Standard AWWA C606) or optional

matching mechanical connections. Be sure that water inlet

markings. PVC piping should not be used.

Loading...

Loading...