IOM 1274-3 • CENTRIFUGAL WATER CHILLERS 32 www.DaikinApplied.com

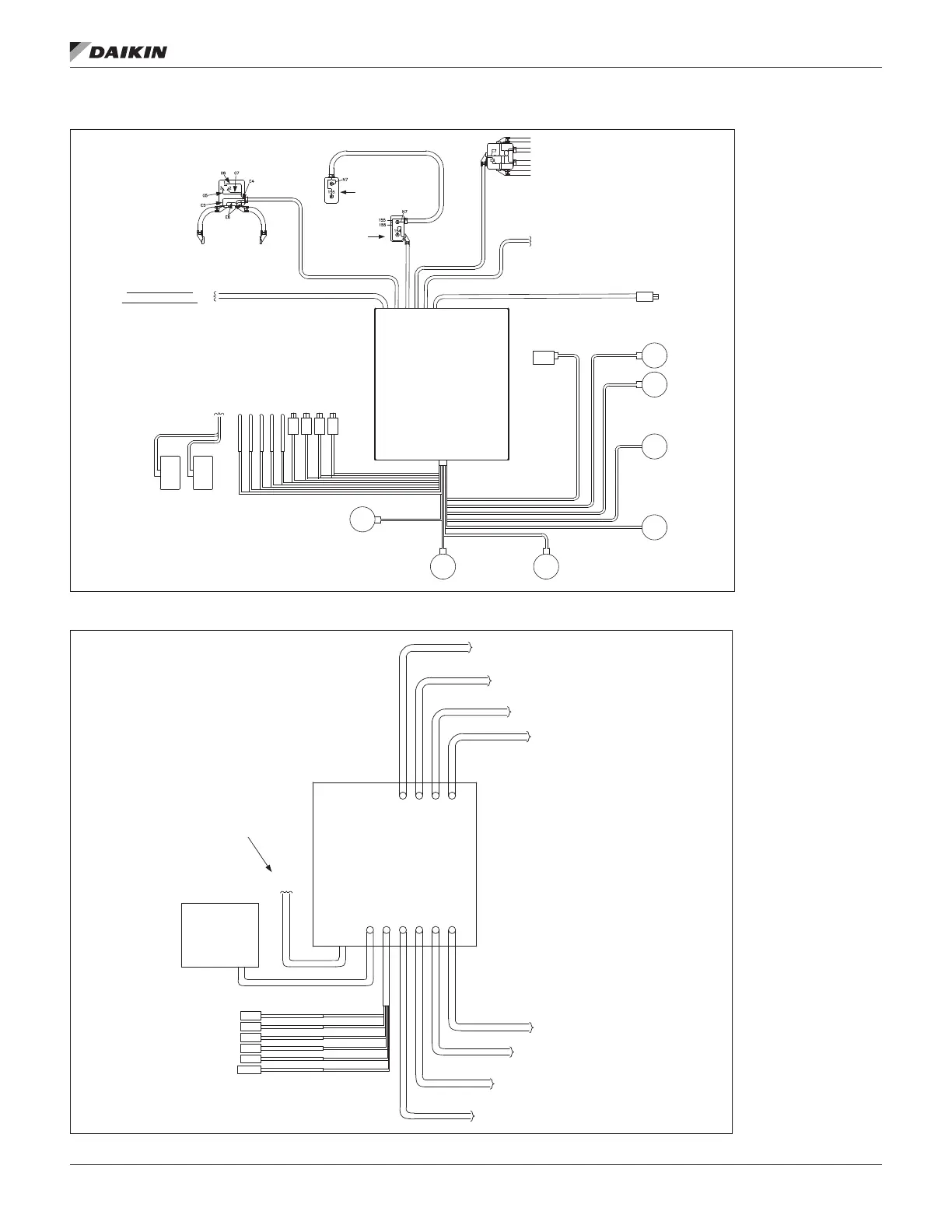

Figure 30: Compressor Control Panel Electrical and Sensor Connections

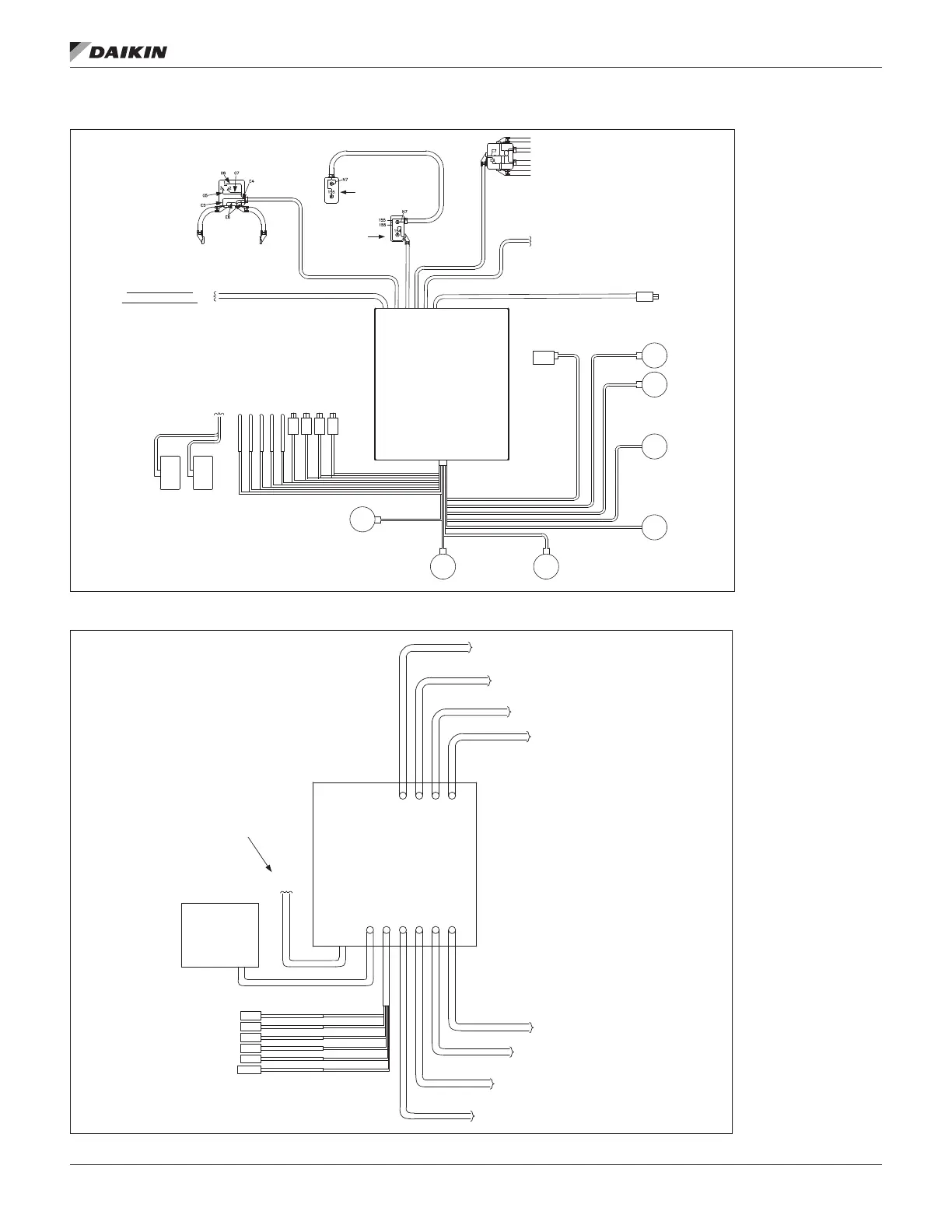

Figure 31: Unit Controller Electrical and Sensor Connections

MOTOR COOLING

SOLENOID

(WDC ONLY)

VANE OPEN

SWITCH

LIQ. INJ.

SOLENOID

HOT GAS

SOLENOID

(OPTION)

VANE CLOSE

SWITCH

VANE CONTROL

SOLENOIDS

OIL COOLER

PROPORTIONAL

VALVE

VFD / STARTER

CONTROL CABLE

OIL PUMP

HEATERS

COMPRESSOR

HEATERS

GUARDISTOR

UNLOAD

LOAD

SECOND HEATER CABLE FROM

COMPR. ON WSC / WDC / WCC

079-087 ONLY.

NUMBER OF HEATERS WILL VARY

DEPENDING ON COMPRESSOR SIZE.

JUNCTION BOX NOT ON ALL UNITS.

2

ND

BOX ONLY

ON 87-126

MOTORS.

CONNECT LEAD

155 T O TERMINAL

IF 2

ND

BOX IS NOT

USED.

(VFD OPTION ONLY)

SEE NOTE 1:

EITHER WIRED DIRECTLY FROM

STARTER

(IF STARTER IS FACTORY MOUNTED,

FREESTANDING, OR FIELD MOUNTED)

OR

LOCATED IN THE

COMPRESSOR TERMINAL BOX

(IF STARTER IS FREESTANDING OR

FIELD MOUNTED)

CLFS

FLOW SWITCHES

ELFS

COMPRESSOR

CONTROL BOX

CS4 OIL SUMP TEMP

CS5 CMP R SUCTI ON TEMP

CS7 CMPR DISCHARGE TEMP

CS10 EVAP. LEAVI NG WATER TEMP

CS9 OIL FEED T EMP

CS6 COND. PRESSURE SENSOR

CS3 EVAP. PRESSURE SENSOR

CS2 OIL FEED PRESSURE SENSOR

CS1 OIL SUMP PRESSURE SENSOR

HIGH

PRESSURE

SWITCH

CABLES ARE FIELD OR UNIT MOUNTED

US2

OPERATOR

INTERFACE

PANEL

COND. GPM SENSOR

(FIELD INSTALLED)

EVAP. GPM SENSOR

(FIELD INSTALLED)

TOWER BYPASS/TOWER VFD

(FIELD INSTALLED)

WATER RESET/REMOTE START-STOP/

MODE/DEMAND LIMIT

(FIELD INSTALLED)

WATER PUMPS

(FIELD INSTALLED)

TOWER STAGING

(FIELD INSTALLED)

ALARMS

(FIELD INSTALLED)

POWER

(FIELD INSTALLED)

UNIT CONTROL BOX

EVAP. ENTERING WATER TEMP.

COND. ENTERING WATER TEMP.

COND. LEAVING WATER TEMP.

US2

US3

US4

US5

US9

US10

LIQUID LINE TEMP.

(OPTIONAL) ENTERING HEAT RECOVERY

(OPTIONAL) LEAVING HEAT RECOVERY

Plan CABLE

UC POWER CABLE

POWE R AND SIGNAL CABLES FOR MONITOR

RUN CABLES TO

COMPRESSOR BOX

Loading...

Loading...