Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

16 REV022019

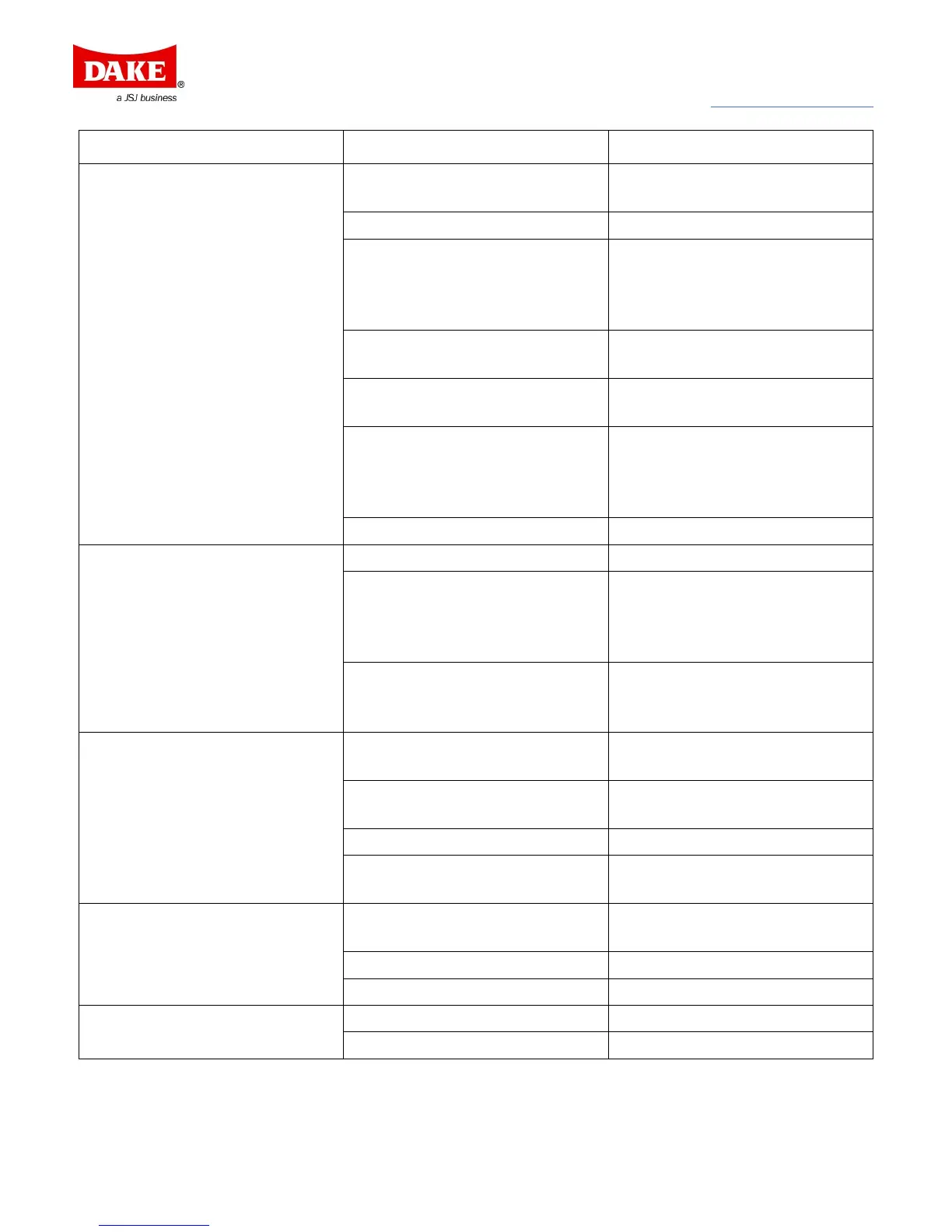

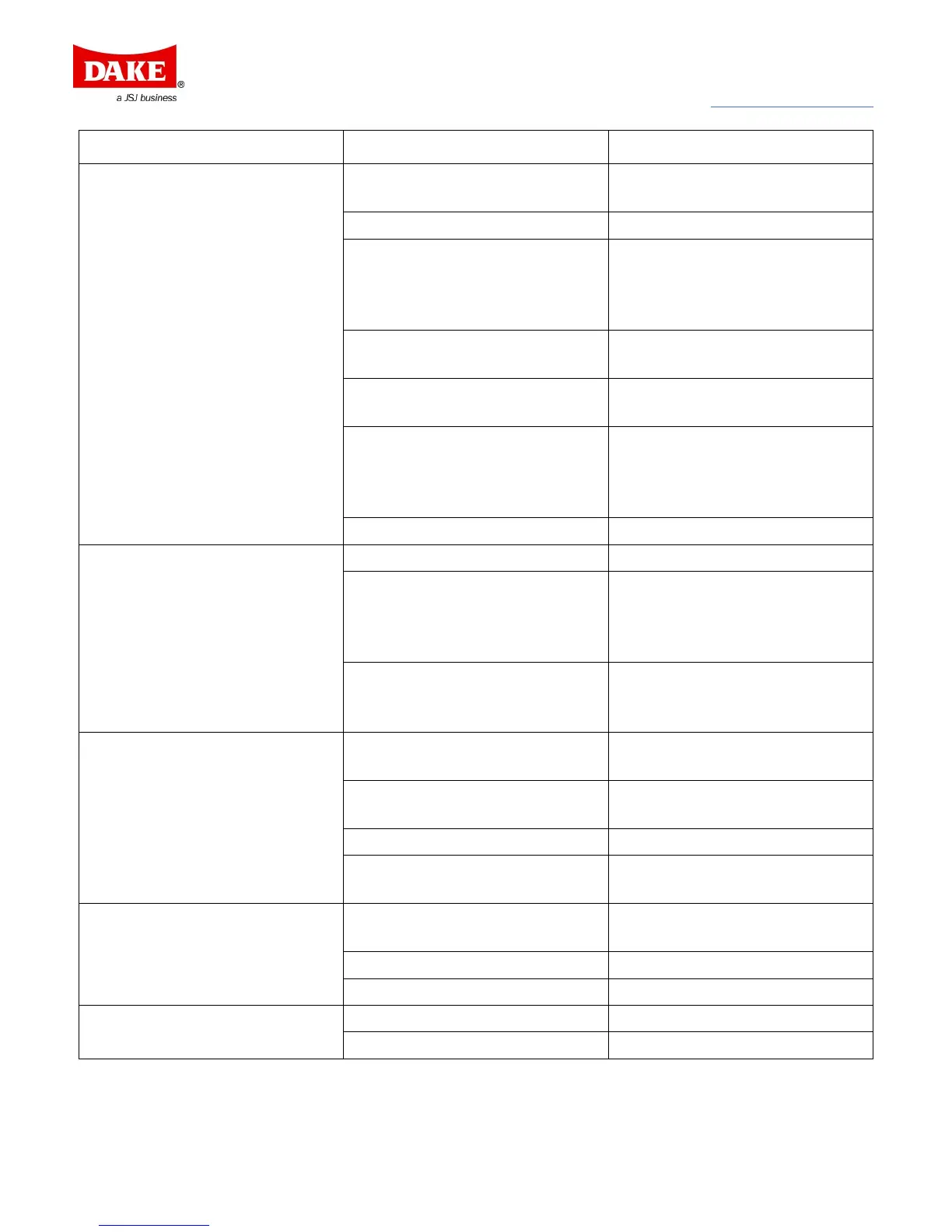

Premature blade dulling

Blade teeth are too coarse

Use a blade with finer

teeth/higher TPI

Feed pressure is too little

Decrease spring tension on

side of the saw. See

“CHANGING FEED RATE”

Hard spots or scale on

material

Reduce speed and/or

increase feed pressure

Work hardening of material

Increase feed pressure by

reducing spring tension

Blade is twisting

Replace with new blade. See

“BLADE REMOVAL AND

INSTALLATION” section in

Unusual wear on side/back of

blade

Blade guide bearings not

adjusted properly

Readjust guide bearings. See

“BLADE GUIDE BEARING

ADJUSTMENT” section of

Blade guide bearing bracket

is loose

Tighten guide bracket using

the adjustment knob (item

Teeth ripping from blade

Blade teeth too coarse for

material

Use blade with a higher TPI

Blade speed too slow

Decrease feed pressure

and/or increase blade speed

Re-clamp work more securely

Blade teeth loading up with

material

Use a coarser tooth blade, or

us brush to remove chips

Rough cuts

Blade speed and/or feed

pressure is too high

Lower blade speed and/or

feed pressure

Blade tension is too loose

Increase tension on the blade

Blade is twisting

Blade tension is too high

Loading...

Loading...