Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

8 REV022019

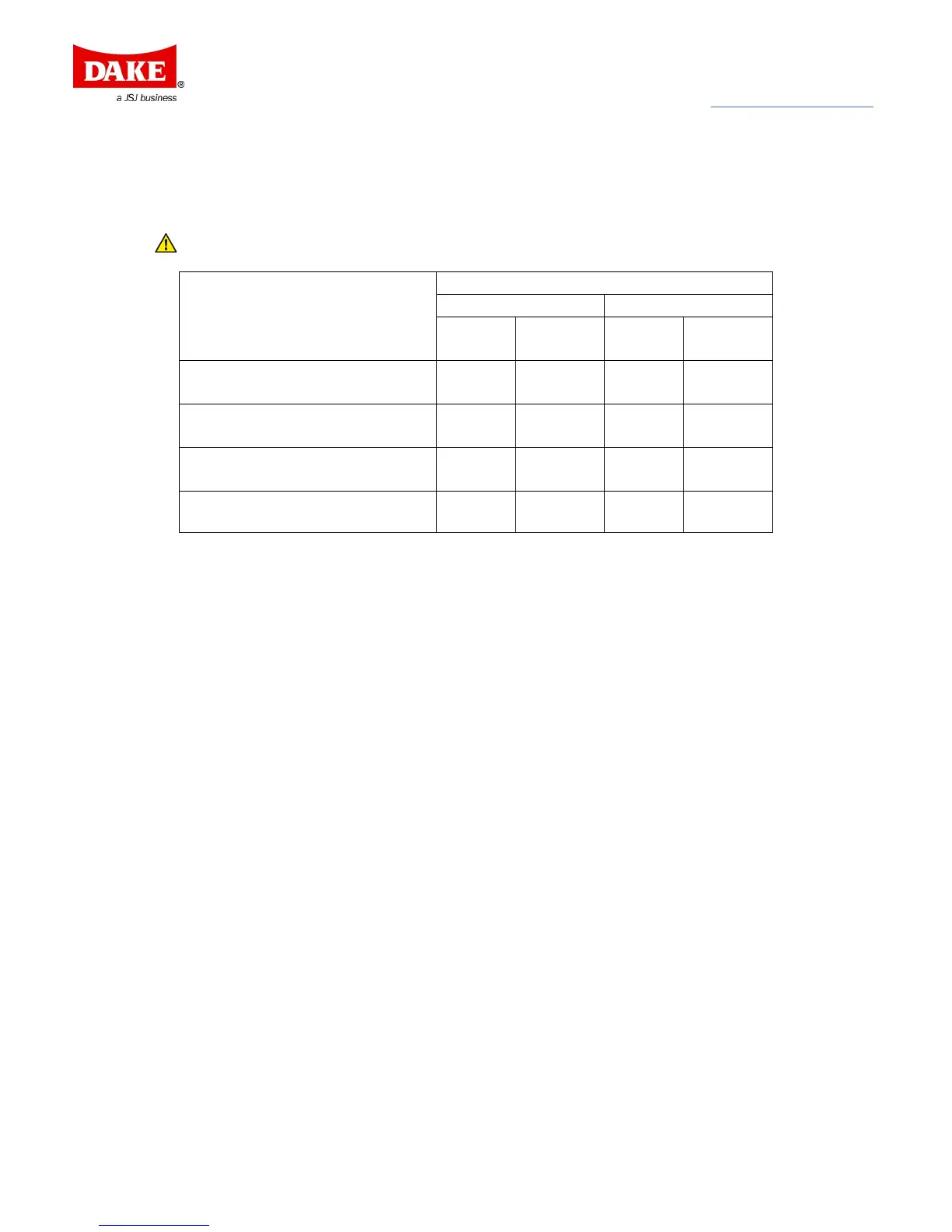

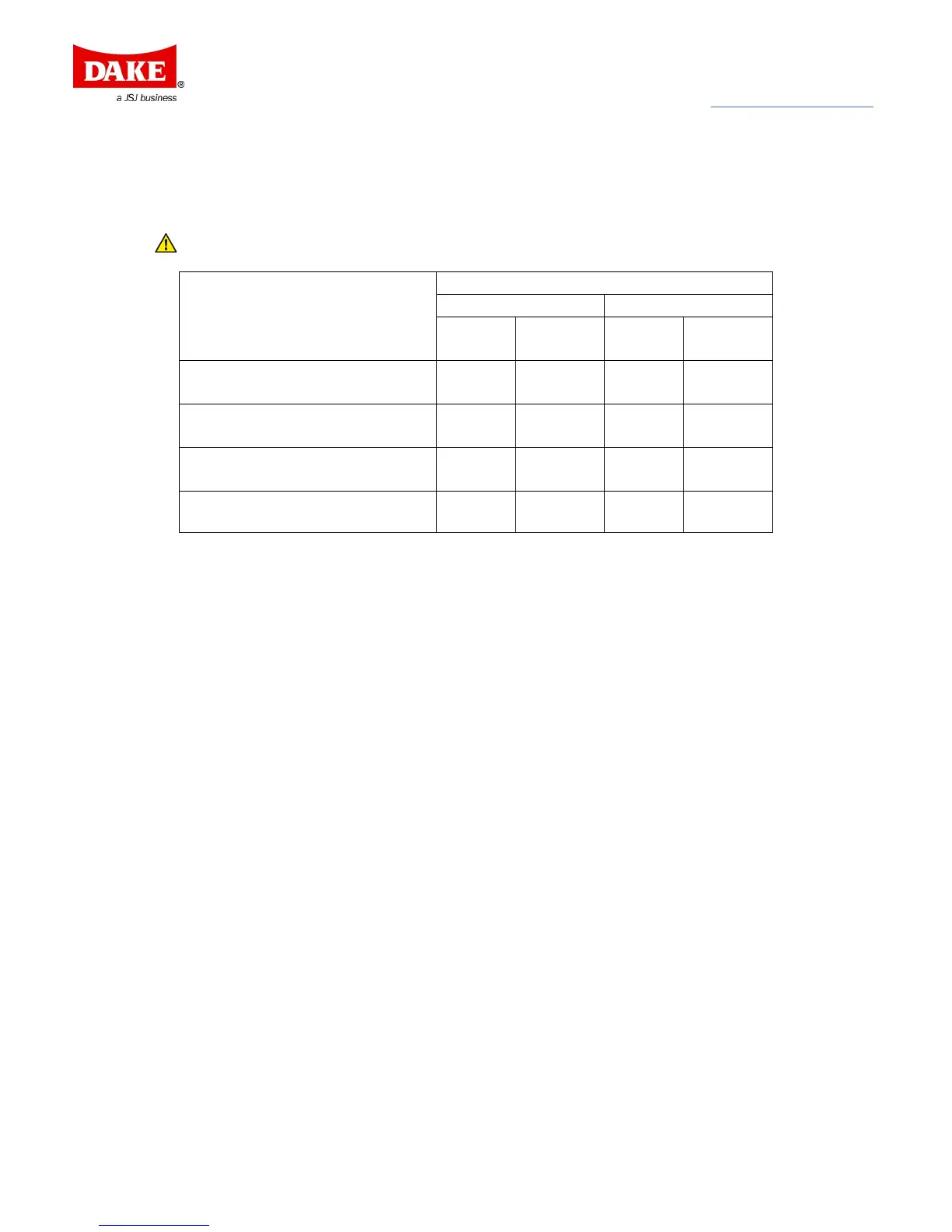

BLADE SPEEDS

Band speed recommendations presented on this chart are approximations and are to be used

as a starting point for most applications. For exact sawing parameters consult your blade

supplier. 120V outlets use 60 Hz columns.

Material

Tool, Stainless Alloy Steels,

Bearing Bronze

85 98 70 81

Med. to High Carbon Steels,

Hard Brass or Bronze

130 164 110 135

Low to Med. Carbon Steel,

Soft Brass

180 246 150 203

Aluminum, Plastic 235 328 195 270

COOLANT

Use a water-soluble coolant

Coolant is mixed 10:1, 10 parts water to one-part coolant. Once the coolant is mixed pour it into

the tray and let it run down into the reservoir. If a lot of coolant pools on one side of the tray the

saw may need to be leveled to let all the coolant drain from the tray equally and ensure all of the

coolant in the system is cycled when cutting.

OPERATION

VICE

Quick Vise: To open the quick vice to accept the workpiece, turn the vice handwheel counter-

clockwise 1/2 a turn. This will allow the outer jaw of the vice to move freely along the screw.

Place workpiece into the vice and use the handwheel, turning clockwise to tighten the vice

securely around your workpiece.

Loading...

Loading...