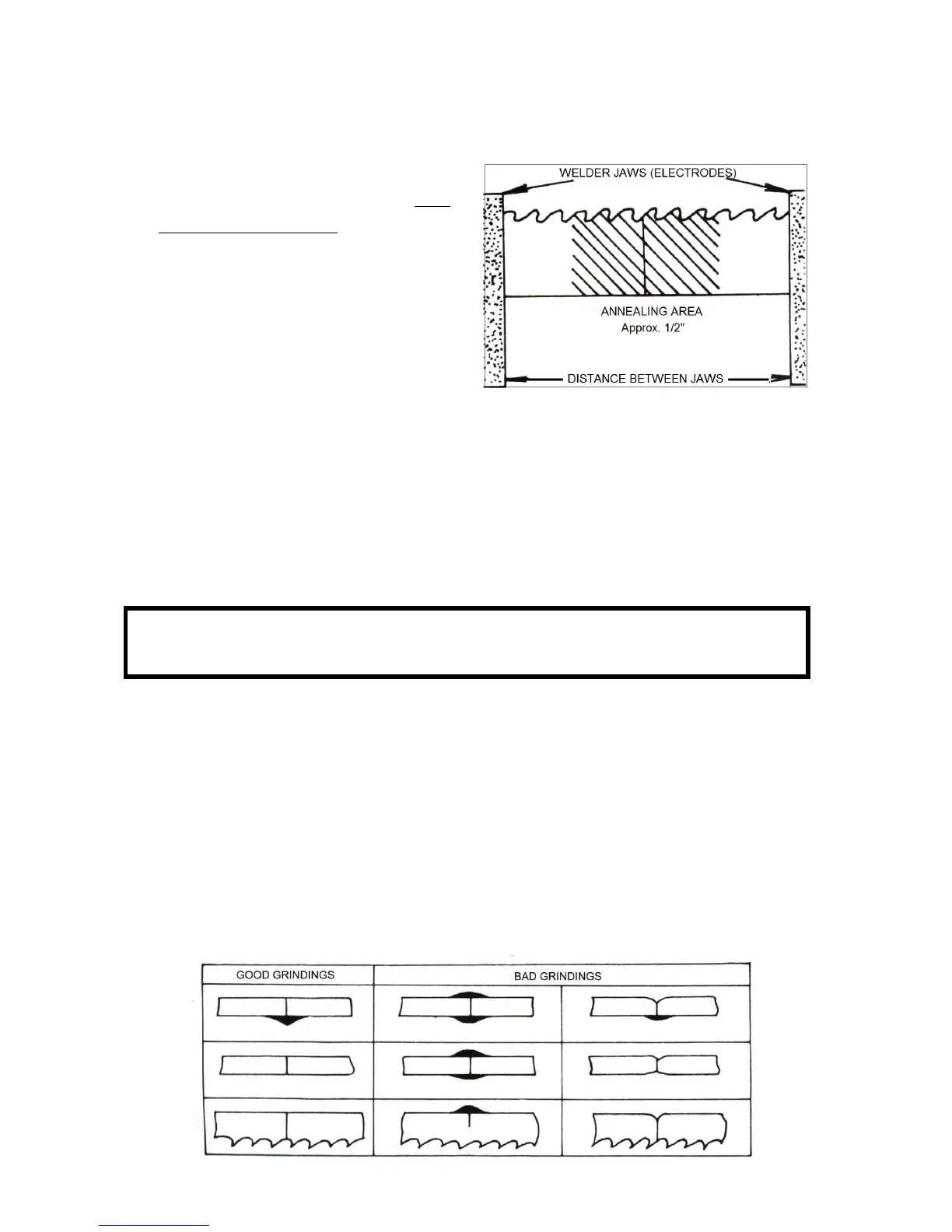

ANNEALING (Bi-Metal)

Set up blade for annealing as mentioned above for carbon blades steps 1 & 2.

Heat the band slowly by jogging the

annealing switch button until the weld

just begins to emit light (this would be

the dullest red color) or minute puff of

smoke. The desired color may not be

visible in normal room light. Always

shade the weld area with your hand.

Cool the weld quickly by releasing the

annealing button. Repeat this

operation 4 or 5 times.

▲NOTE: This procedure should be followed both before and after grinding

BI-METAL Blades.

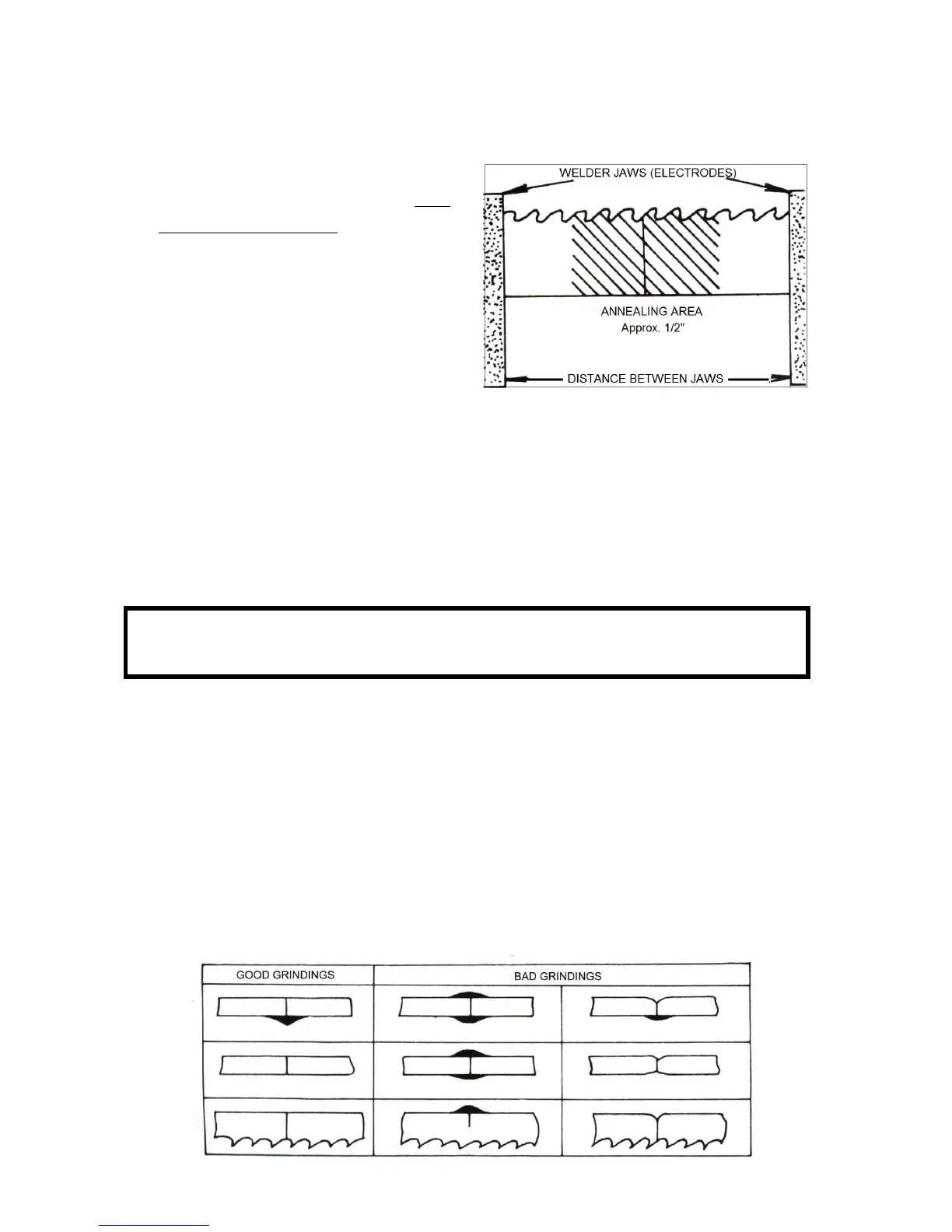

GRINDING THE WELDED BLADE

▲ WARNING

Keep hands away from rotating grinding wheel. When not in use make, sure

wheel is covered with built in cover

After welding, the blade must be dressed to remove excess metal or flash from the weld.

Grind the welded area down to the same thickness as the rest of the band. Handle the blade

carefully.

Grind Carefully: do not hit the teeth; or grind deeper than the thickness of the blade; or

overheat the weld area. Be sure to remove flash from the back edge of the blade. Any flash

or “stub” teeth that project beyond the normal set or height of the other teeth must be

ground off.

Anneal the welded area that was ground again. Anneal 2 or 3 times using a lower

temperature. (Just as area starts to emit light)

Loading...

Loading...