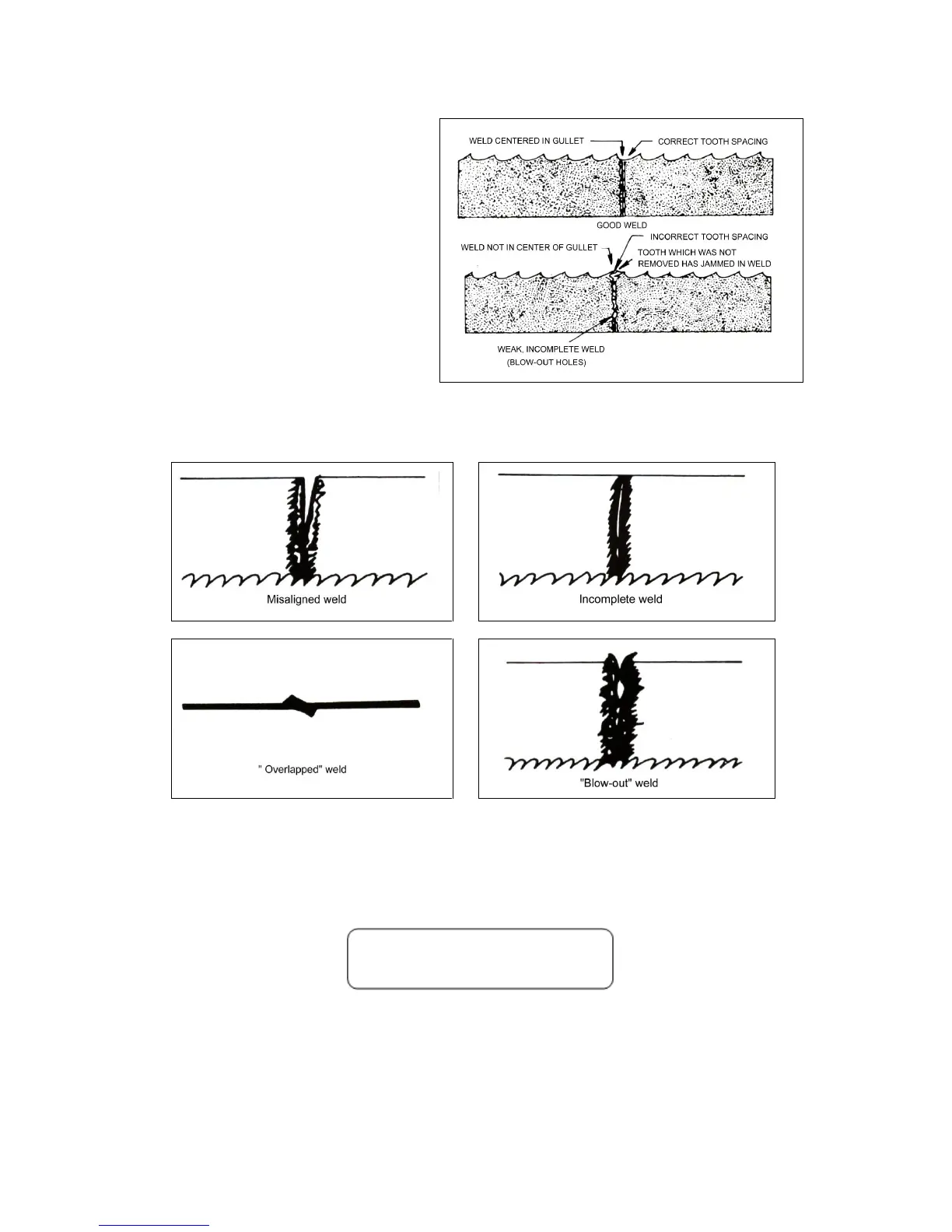

When the blade is removed from the

welder it should be inspected

carefully.

The spacing of the teeth should be

uniform and the weld should be

located in the center of the gullet.

Major jaw misalignment is easily

noted at this time from the weld

appearance. See the trouble shooting

chapter if the weld is imperfect.

▲CAUTION: This welder is designed for intermittent use. Repeated welding

within a short period of time may cause the welder to overheat.

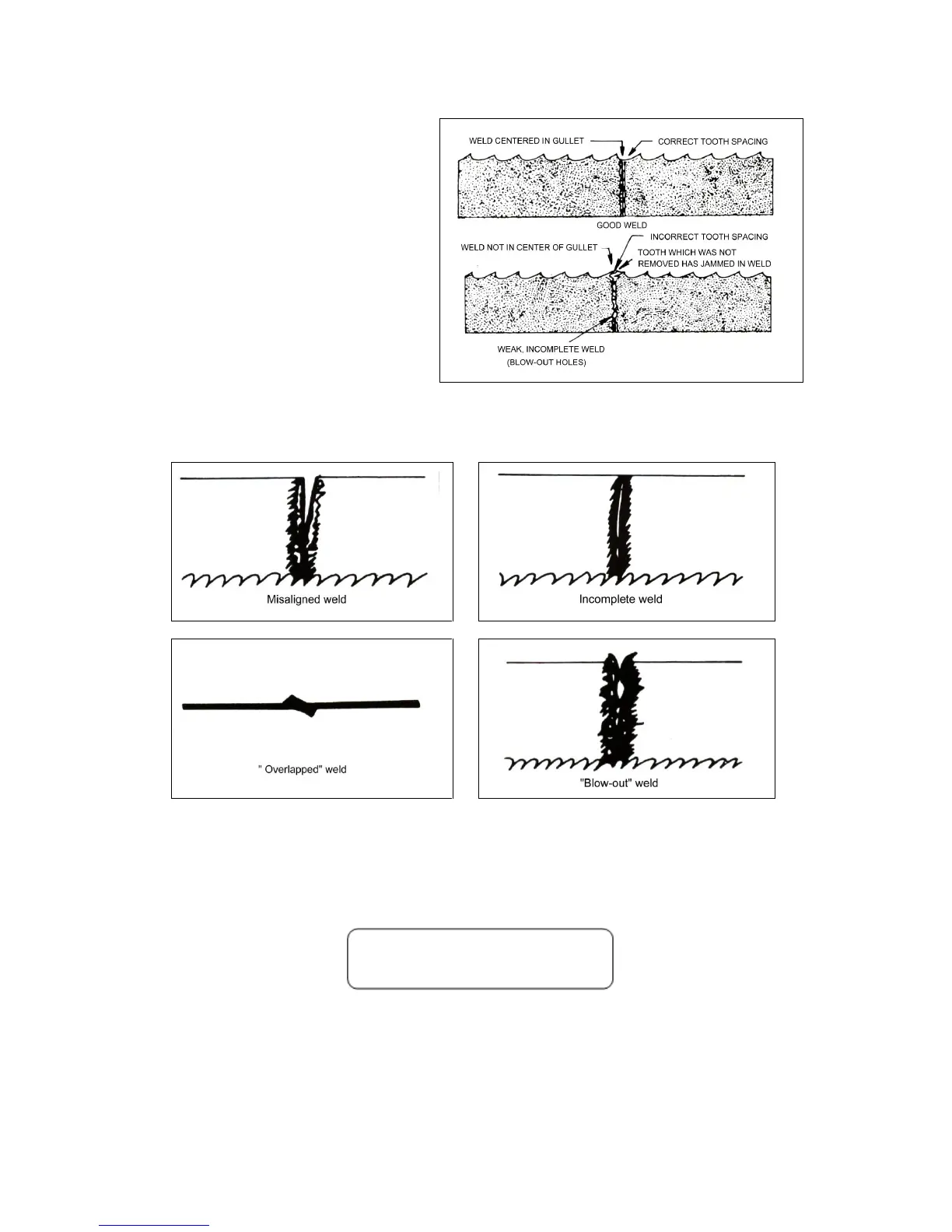

MISALIGNED WELD

(1) Dirt or scale on jaws or blade.

(2) Blade ends not cut off square.

(3) Blade ends not correctly aligned when clamped in jaws.

(4) Worn jaws or inserts.

(5) Jaws are not aligned correctly.

Loading...

Loading...