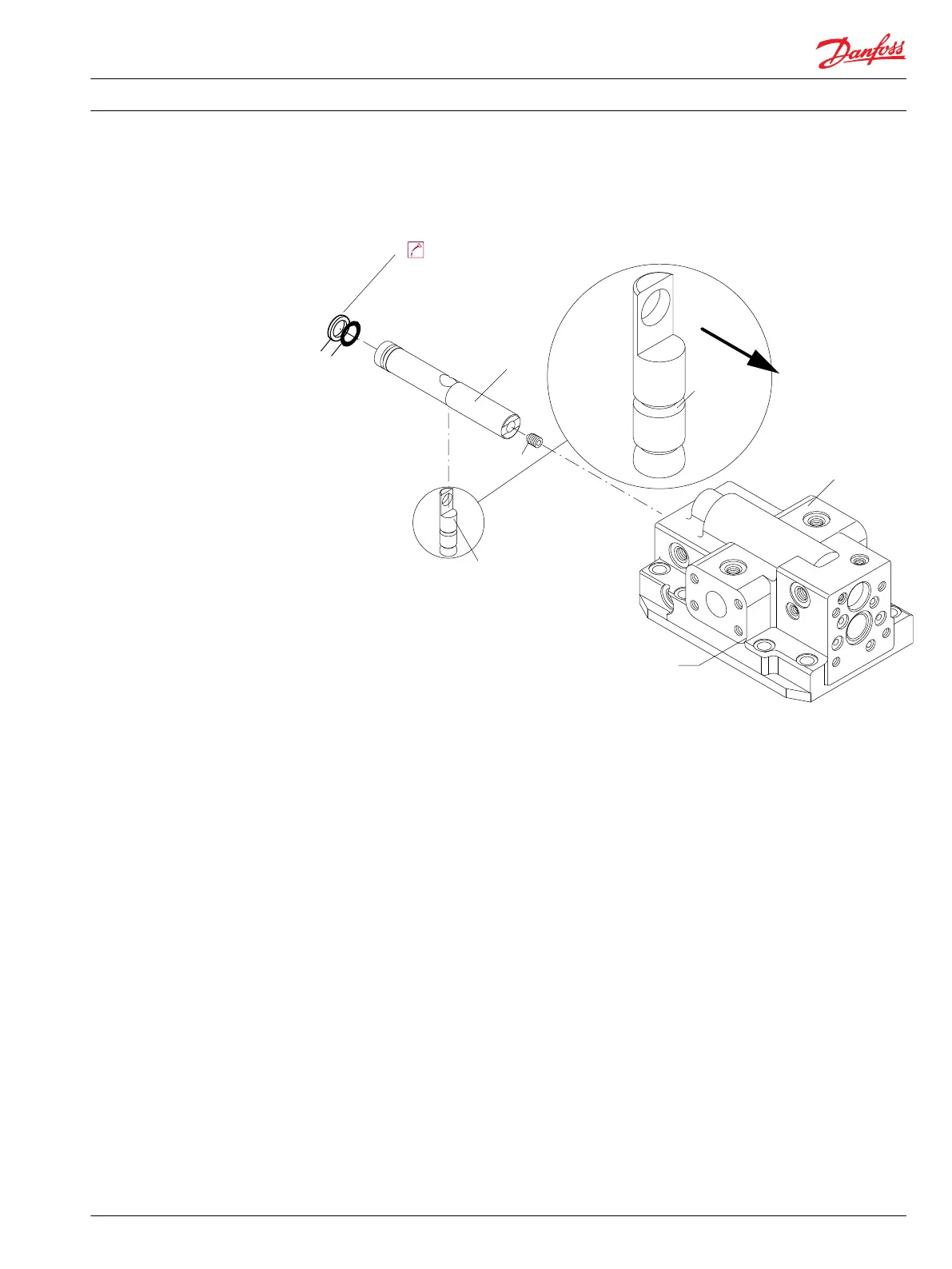

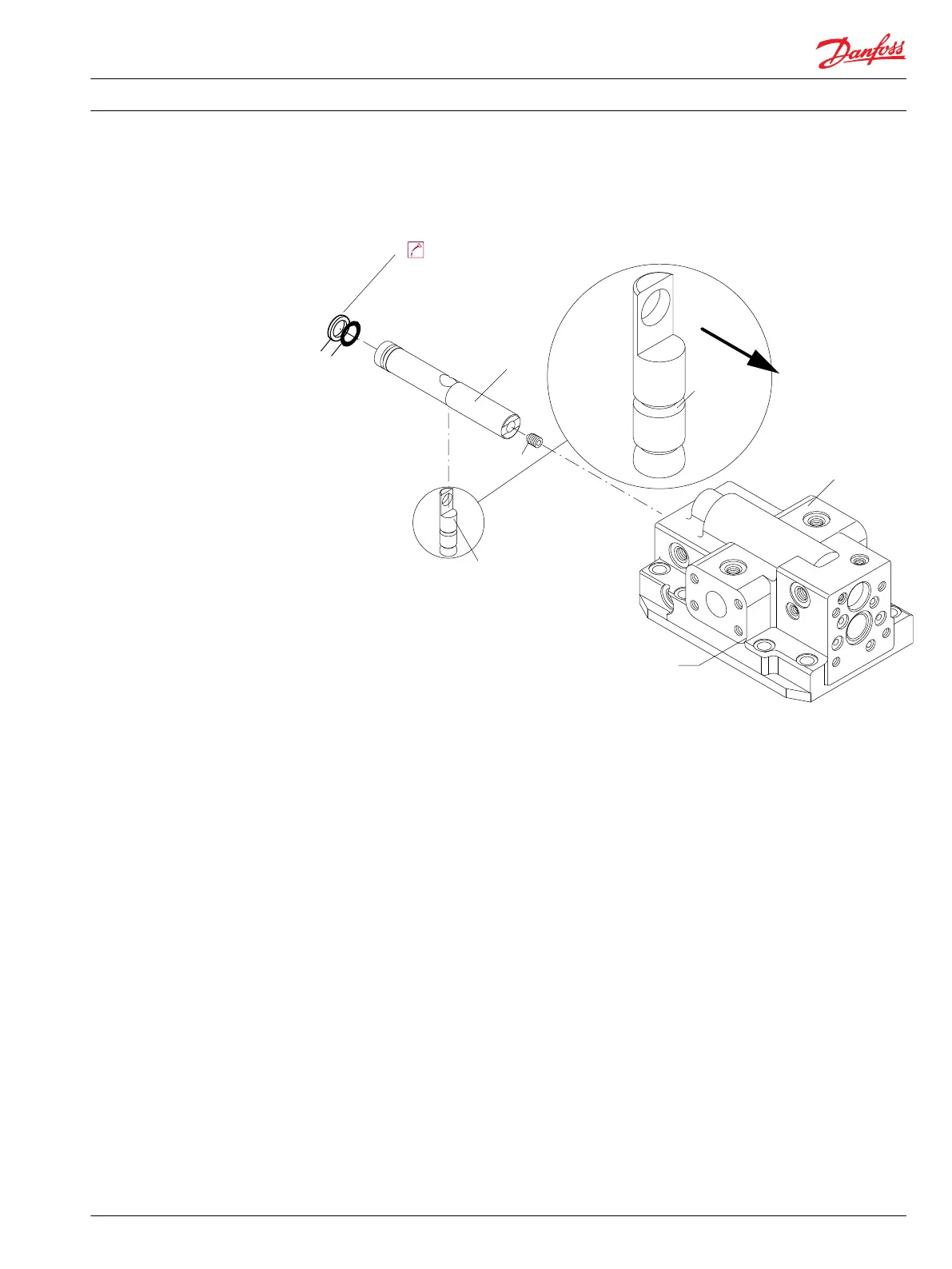

2. Install the cone-point set screw (F26) so that its point enters the groove in the feedback fork (F24) /

setting lug. Do not tighten the set screw yet. See page 21 for final assembly instructions.

Cone-point screw and feedback fork

F24

(110, 160, 250)

End cap (side port style shown)

typical for 110, 160, and 250 frame sizes

G10

F26

F12

Multi-function

block/control

Groove

Lubricate with hydraulic fluid

F10

F11

P104 097

All frame sizes

1. Position feedback fork (F30) (060 cc) or feedback fork/setting lug (080 cc - 250 cc) perpendicular to

the setting piston for proper control spring operation.

2. Insert a 26.9 mm [1.06 in] diameter rod, with the end machined perpendicular to its axis, into the

valve sleeve bore in the end cap. Align the fork while tightening the cone-point set screw (F26).

3. Using a 3 or 5 mm internal hex wrench, torque the cone-point set screw to 5 N•m [44 lbf•in].

4. Install and torque the lock screw (F28) to

•

7 N•m [62 lbf•in] using a 3 mm internal hex wrench for a 60 cc motor

•

34 N•m [25 lbf•ft] using a 5 mm internal hex wrench for the 80 cc through 250 cc motors

Repair Instructions

Series 51 and 51-1 Bent Axis Motors Repair Instructions

Assembly

11009449 • Rev BA • December 2014 21

Loading...

Loading...