4. Tighten the screws by hand in a double-X pattern while rotating the motor shaft to ensure proper

positioning of the synchronizing shaft rollers.

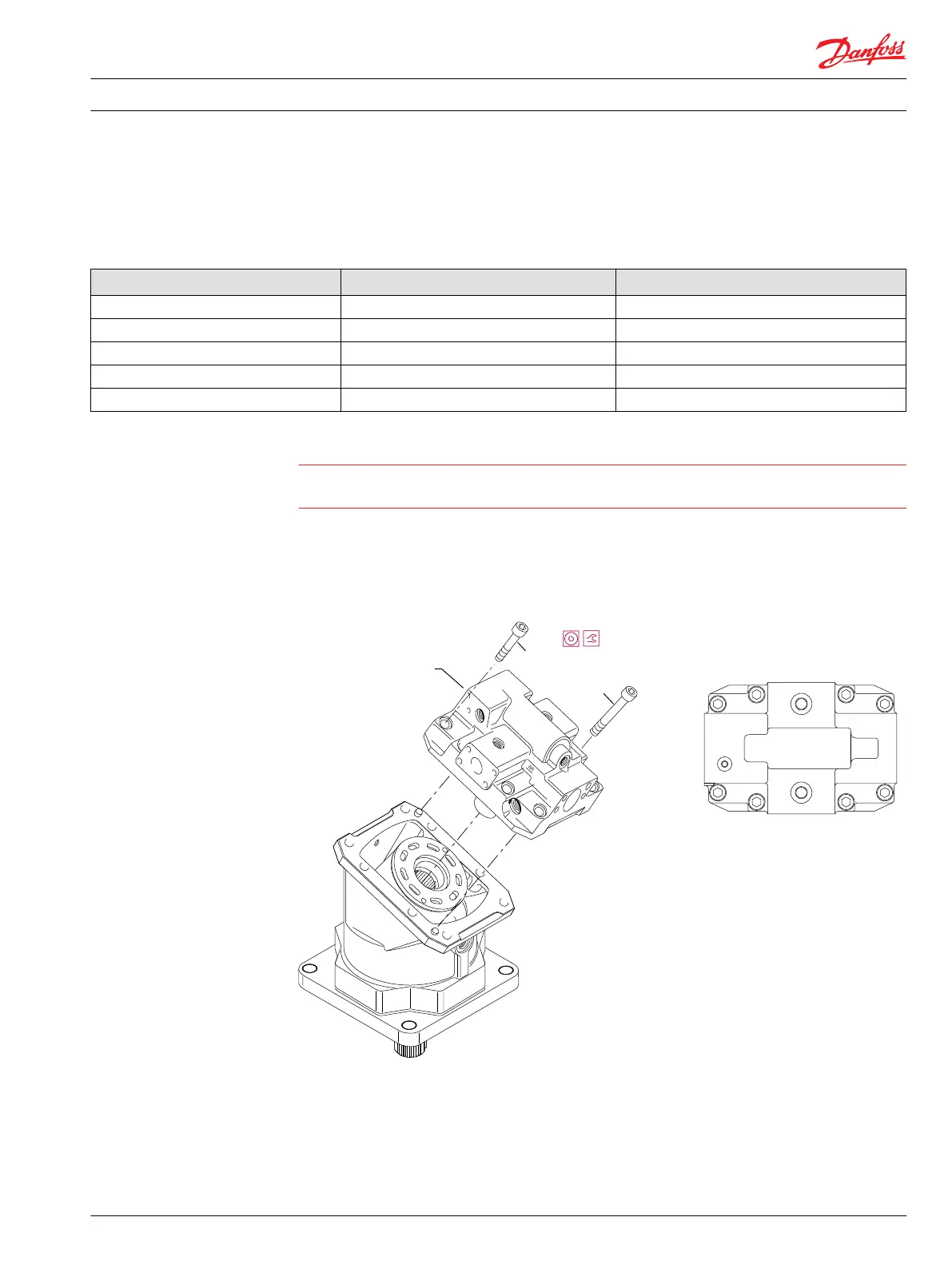

5. When the end cap is in position, torque the screws in a double-X pattern as shown in the table:

Endcap screw torque

Frame size Wrench size Torque N•m [lbf•ft]

060 8 mm 66 [49]

080 8 mm 78 [58]

110 10 mm 115 [85]

160 10 mm 135 [100

250 12 mm 213 [157]

Caution

Do not force the end cap into position on the housing. If necessary, reassemble the components to

ensure proper alignment.

6. Recheck the end cap screw torque.

7. Reinstall the minimum angle servo cover, control springs (if used), 4-way valve spool and sleeve (if

used), and control and multifunction block (if used). Refer to Series 51 and 51-1 Service Manual,

11008567 for instructions.

Torquing pattern

G34

SAE flange version shown

cartridge version similar

G32

Endcap assembly

with valve segment

Double-X pattern torquing sequence

(110 frame size with side port end cap shown)

3/11

7/15

P104 106

2/10

5/13

6/14

1/9

4/12

8/16

see table

Following procedures in the Series 51 and 51-1 Service Manual, 11008567: Install the control and

multi-function block (if installed). Install the 4-way valve spool and sleeve (if installed). Install the

threshold springs and guides. Install the control springs (if installed). Install the ramp springs and

guides (if installed). Install the minimum angle servo cover from the motor. Install the loop-flushing

valve and charge relief valve.

Repair Instructions

Series 51 and 51-1 Bent Axis Motors Repair Instructions

Assembly

11009449 • Rev BA • December 2014 31

Loading...

Loading...