3. Turn the sensor counterclockwise (CCW) 1/2 turn (180°) to establish the nominal gap of 0.71 mm

[0.028 inch].

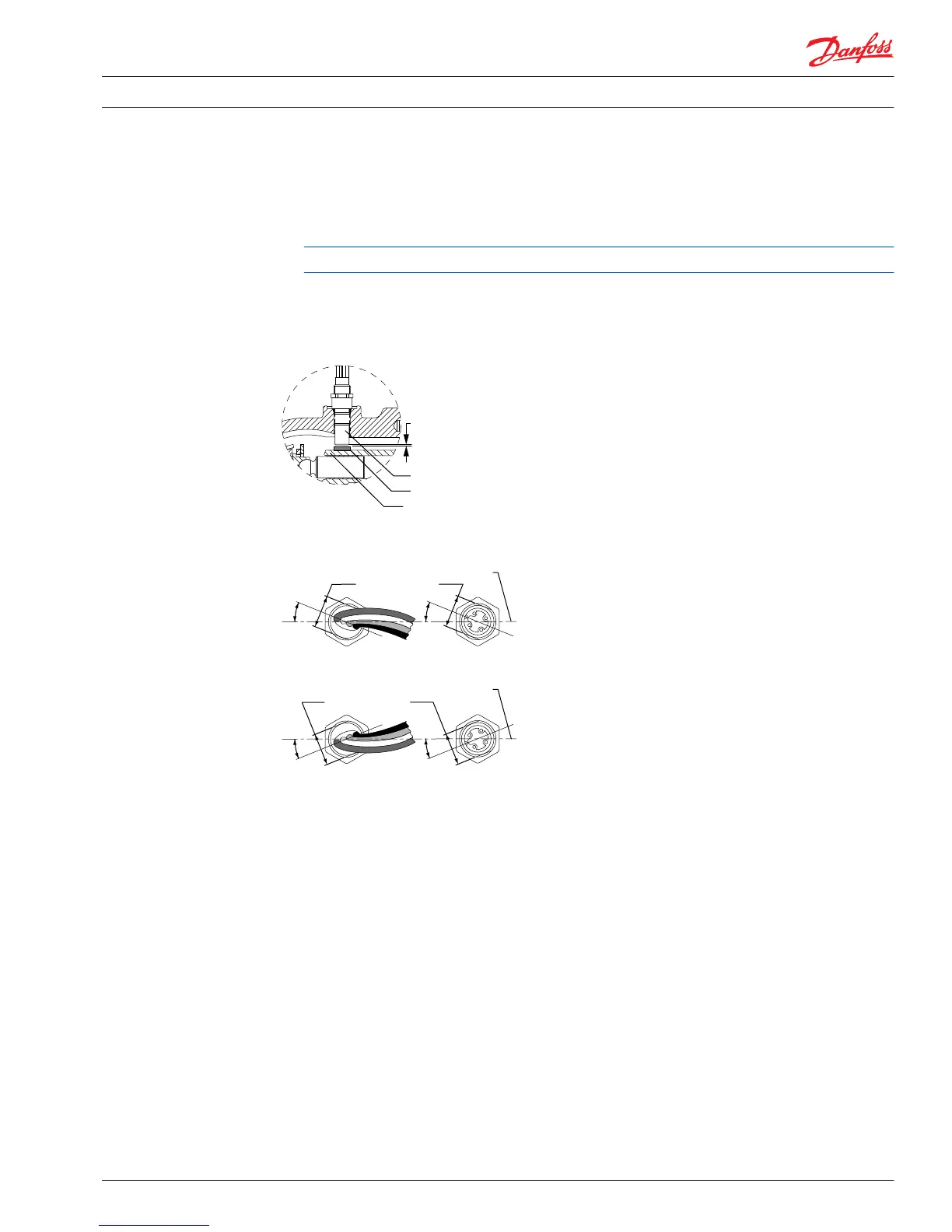

4. Then turn the sensor clockwise (CW) until the wrench flats on sensor body are positioned at a 22°

angle to the pump shaft center line.

Most open-end wrenches have a 22° handle offset.

5. The final sensor position should be between 1/2 (180°) and 1/4 turn (90°) counterclockwise (CCW)

from the point where the sensor contacts the speed ring.

6. Hold sensor in position with a 1/2 inch hex wrench while tightening the lock nut to 13 N•m [10 lbf•ft].

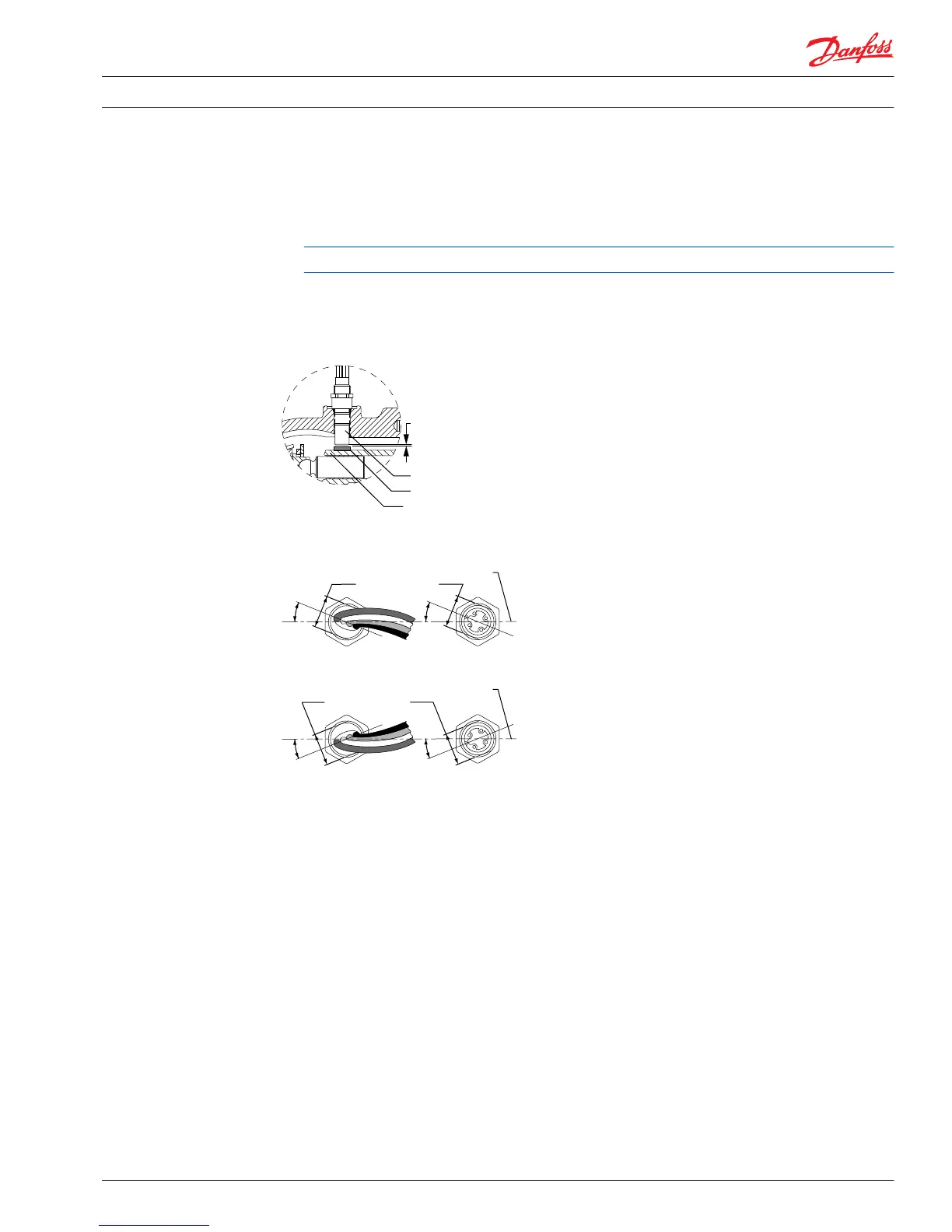

Cross section view of speed sensor in variable pump

Loading...

Loading...