AK-PC 781A Capacity controller RS8HE202 © Danfoss 2017-07 51

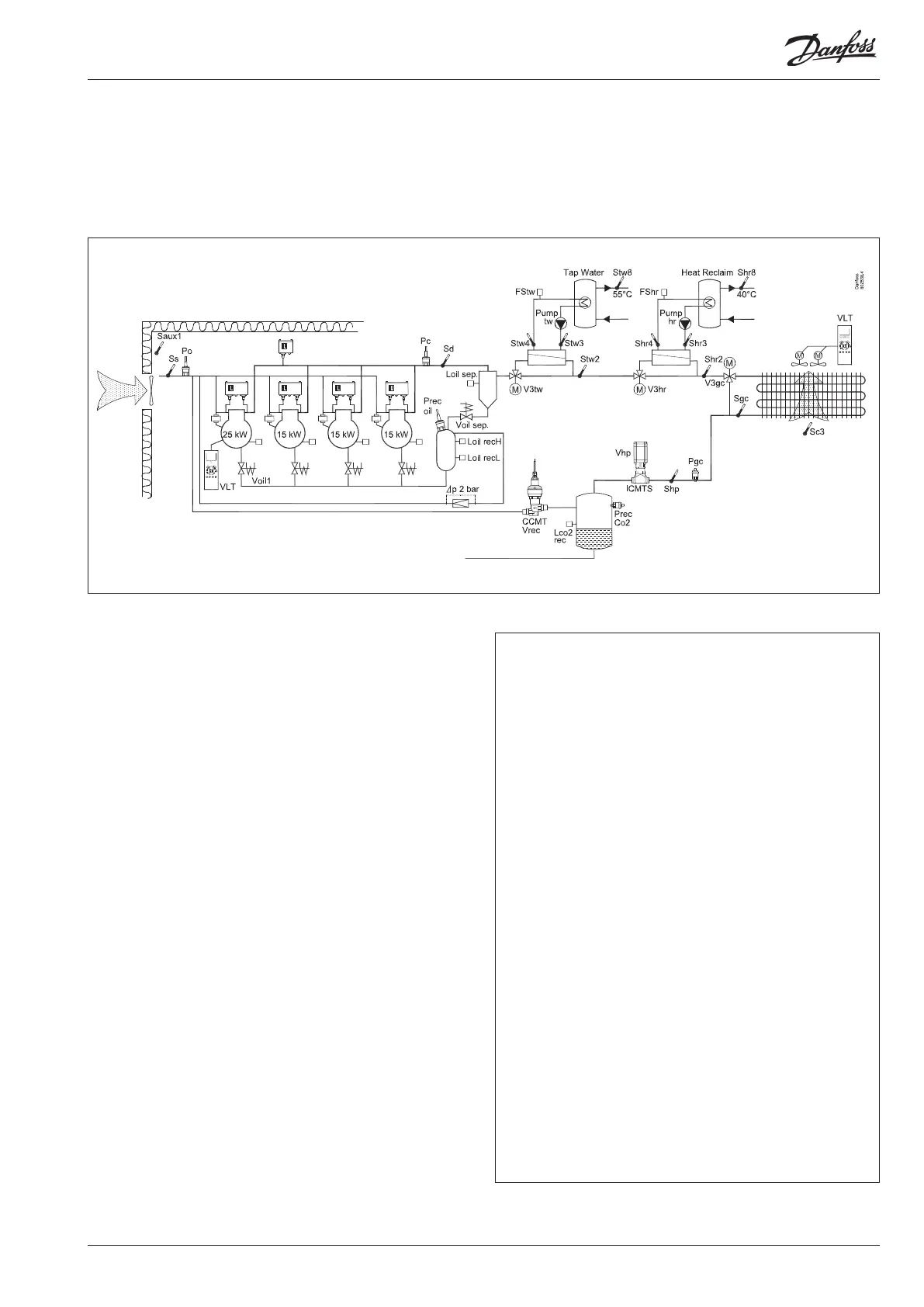

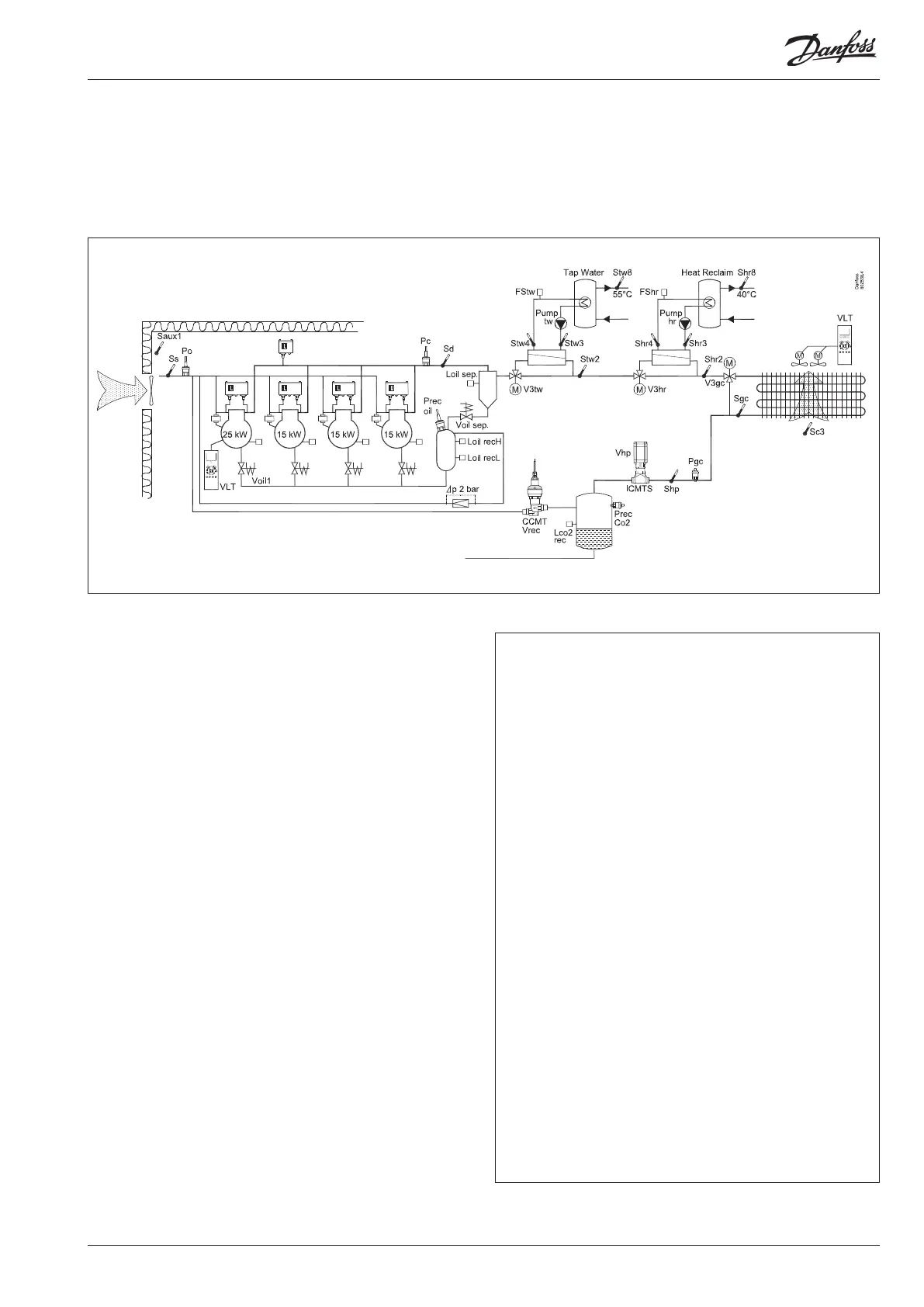

Refrigerating plant example

We have decided to describe the setup by means of an example

comprising a MT compressor group and a high pressure control.

The example is the same as the one given in the "Design" section,

i.e. the controller is an AK-PC 781A + extension modules.

There is also an internal main switch as a setting. Both, this and the

external compressor stop must be “ON” before any adjustment is made.

Warning

The main switch will stop all regulations, including high-pressure regula-

tion.

Compressor Group

• MT circuit

• Refrigerant CO2 (R744)

• Variable compressor and 3 single step compressors

• 4 only compressors with "Best fit"

• Safety monitoring of each compressor

• Common high-pressure monitoring

• Po setting -15°C, night displacement 5 K

• Oil management of each compressor

High pressure control:

• Gas cooler with speed controlled fans (Pgc Max. = 100 bar)

• High pressure control with signal from Sgc and Shp

• Pc regulates floating based on outdoor temperature sensor Sc3

• Control of high pressure valve ICMTS

• Heat recovery for hot tap water. Relay and 0-10 V

• Heat recovery for heating. Relay and 0-10 V

Receivers:

• Monitoring of liquid level of refrigerant

• Control of pressure in refrigerant receiver (reference 34 bar)

• Control of pressure in oil receiver

Fan in plant room

• Thermostat control of fan in engine room

Safety functions:

• Monitoring of Po, Pc, Sd and superheat in suction line

• Po max = -5°C, Po min = -35°C

• Pc max = 103.5 bar

• Sd max = 120°C

• SH min = 5 °C, SH max = 35 °C

• Monitoring of low and high level in oil receiver

Other

• Start/stop of heat recovery tw and hr

• External compressor stop used

Loading...

Loading...