180R9346 | AQ240486503020en-001702 | 21© Danfoss | 2023.03

Operation guide Installation, Operation and Maintenance APP 53-92 pumps

2. Benets

1. Introduction

• Zero risk of lubricant contamination:

- Oil lubricants are replaced with the

pumped medium, water, so there is no

contamination risk from the pump.

• Low maintenance costs:

- Ecient design and all-stainless steel

construction ensure exceptionally long

life. When Danfoss specications are

met, service intervals of 8,000 hours can

be expected. Service is easy, and can be

carried out on-site due to the simple

design and few parts.

• Low energy costs:

- The highly ecient axial piston design

provides the lowest energy

consumption of any comparable pump

on the market.

• Easy installation:

- The most compact and lightest design

available.

- The pump can be installed horizon-

tally in dierent positions rotating it

around the shaft (see section 10 for

example).

No pulsation dampeners necessary due

to extremely low pressure pulsation.

- Powered directly by electric motors or

combustion engines (with special

coupling).

- All pumps are supplied with an

integrated ushing valve that allows the

uid to ow from inlet to the outlet,

when the pump is not running.

• High reliability:

- All parts are made of high corrosion

resistant materials e.g. Duplex

(EN1.4462/ UNS S31803) and

Super Duplex (EN1.4410/UNS S32750)

stainless steel and carbon reinforced

PEEK.

• Certied quality:

- Available with positive material

idencation (PMI) certication on

request.

- ISO 9001, ISO 14001, IAFT 16949

- ATEX certication available for APP S (all

Super Duplex) and APP S 674 (API).

Please see relevant data sheets.

3. Application examples

Danfoss APP pumps are built into a broad range

of RO desalination plants around the world:

• Containerized solutions for hotels, resorts

and residences on islands and in coastal

regions

• Mobile systems for humanitarian and

military organizations

• Onboard systems for ships and yachts

• Oshore platforms for the oil and gas

industry

• Municipal and regional waterworks

The Danfoss range of APP high-pressure pumps

is designed according to EN 809 for use in RO

applications with low viscosity and corrosive

uids such as sea water.

Danfoss APP pumps are positive displacement

pumps with axial pistons that move a xed

amount of water in each cycle. Flow is propor-

tional to the number of input shaft revolutions

(rpm).

Unlike centrifugal pumps, they produce the same

ow at a given speed no matter what the

discharge pressure.

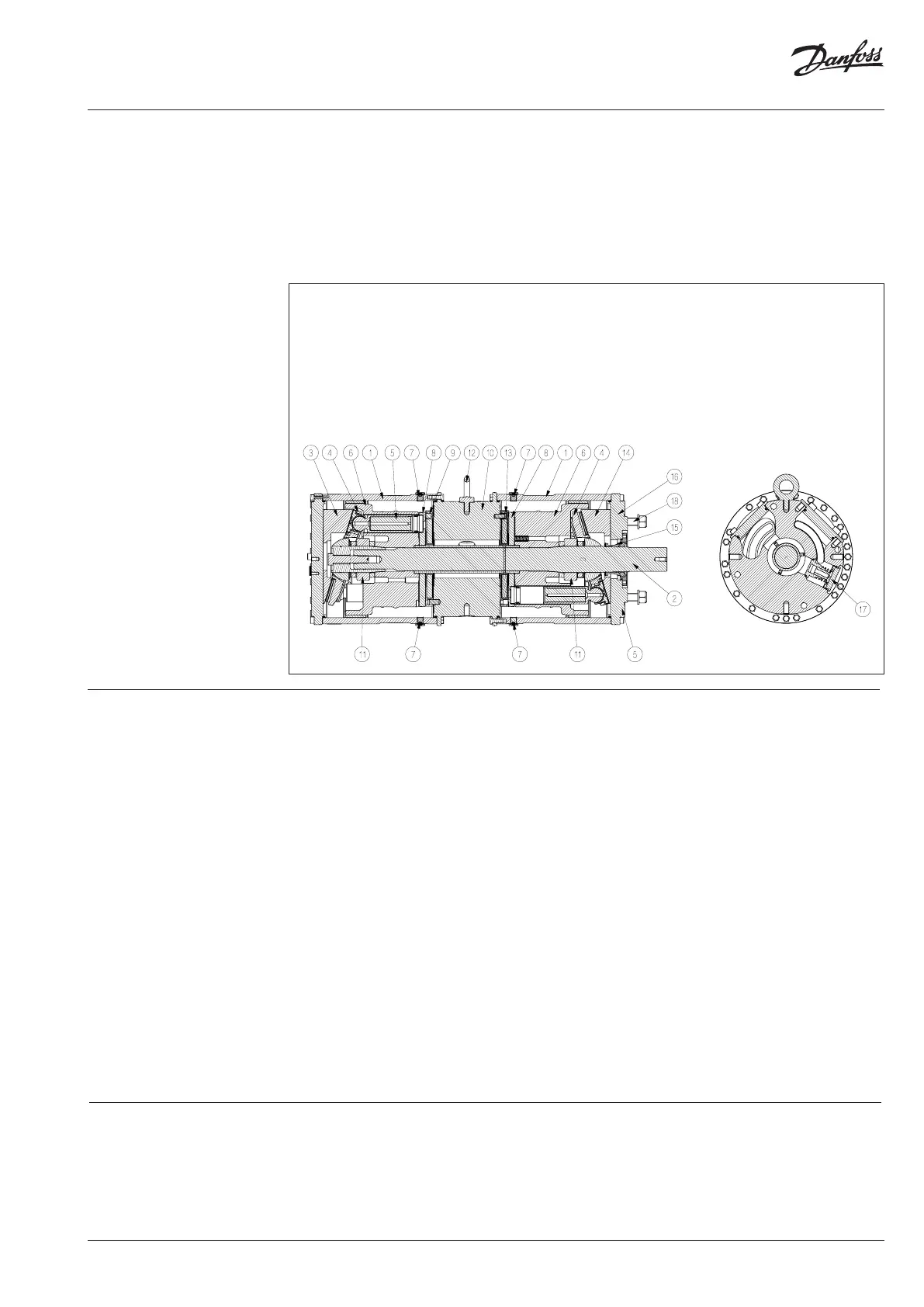

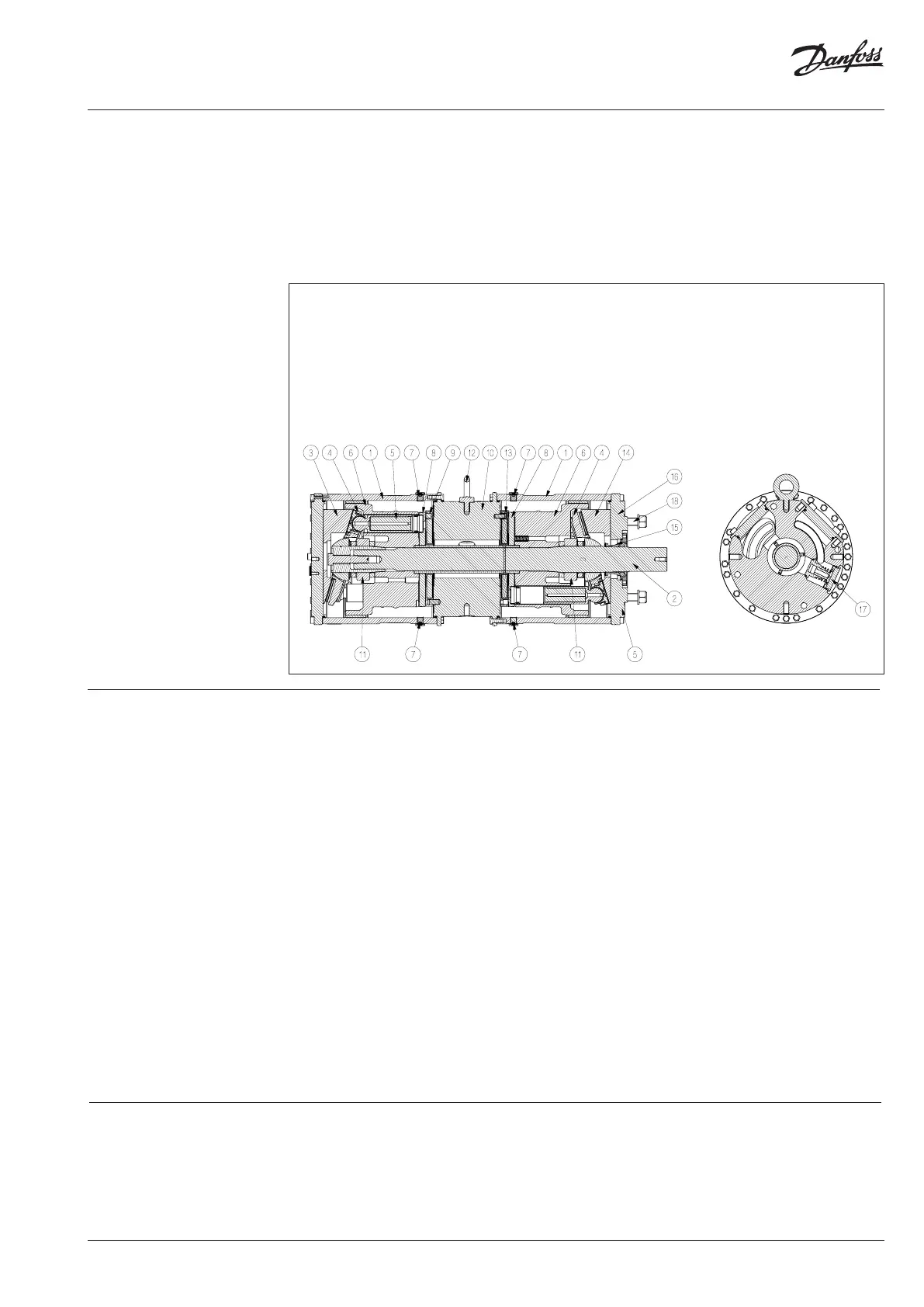

The sectional drawing below illustrates the main

components of the APP 53-92 pump range.

1 Housing

2 Shaft

3 Swash plate (non drive end)

4 Retainer plate

5 Piston

6 Cylinder barrel

7 Bleeding / drain plug

8 Valve plate

9 Port plate (non drive end)

10 Center ange

11 Spring cartridge

12 Eye bolt

13 Port plate (drive end)

14 Swash plate (drive end)

15 Shaft seal

16 Motor ange

17 Flushing valve

18 Tail stock screws

Loading...

Loading...